Graphene composite dry powder with high solid content and preparation method, epoxy zinc-rich coating and preparation method

A graphene composite, high solid content technology, applied in the field of nanomaterials, can solve problems such as unfavorable application and large solvent usage, and achieve the effects of long salt spray resistance, slow solvent volatilization rate, and easy dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0101] The preparation method of the graphene composite dry powder with high solid content is to disperse the graphene in the high volatilization rate solvent first, then mix the high volatilization rate solvent dispersed with graphene and the low volatilization rate solvent, and then separate the high volatilization rate solvent by distillation. solvent, the graphene composite dry powder with high solid content can be obtained. Specific steps are as follows:

[0102] S101: adding graphene, dispersant and stabilizer to a high-volatility solvent to disperse, stir and grind to obtain A solution;

[0103] S102: Add a low-volatility solvent to the A solution, disperse and stir, and obtain a B solution;

[0104] S103: distilling solution B to obtain graphene composite dry powder with high solid content.

[0105] Mix graphene, dispersant, stabilizer and high volatilization rate solvent, and disperse and grind graphene evenly in high volatilization rate solvent; then add low volati...

Embodiment approach

[0109] As a second embodiment of the present invention, an epoxy zinc-rich coating is provided, including: epoxy resin solution, bentonite, zinc powder, iron-titanium powder, graphene composite dry powder with high solid content, polyamide wax slurry , polyethylene wax, xylene and n-butanol. The mass ratio of epoxy resin solution, bentonite, zinc powder, iron-titanium powder, graphene composite dry powder with high solid content, polyamide wax paste, polyethylene wax paste, xylene and n-butanol is 25:2.5:30:30: (2.5-10):0.5:1:7:3. The epoxy resin in the epoxy resin solution accounts for 75 wt%, and the solvent is a mixed solution of xylene and n-butanol. Compared with the previous use of low-content graphene composite slurry, epoxy zinc-rich coatings use high-solid-content graphene composite dry powder, which greatly reduces the amount of graphene material added; while high-solid-content graphene composite dry powder is half In solid state, graphene is well dispersed, only n...

Embodiment 1A

[0120] This example shows a preparation process of graphene composite dry powder with high solid content.

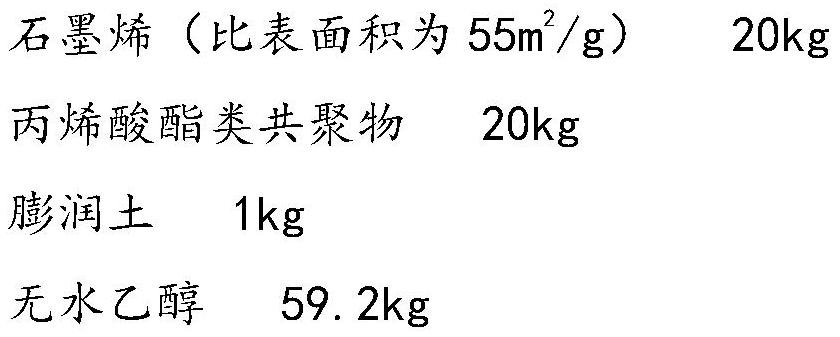

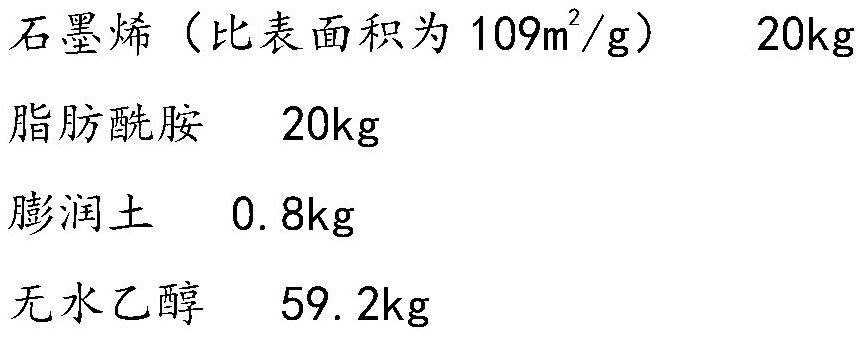

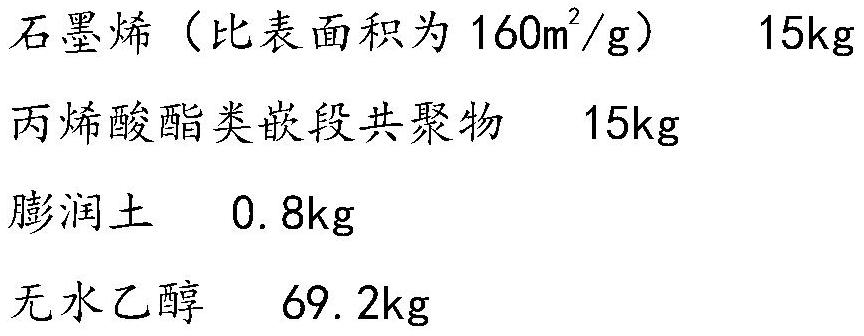

[0121] Step 1): Provide the following raw materials:

[0122]

[0123] Step 2): Prepare A solution:

[0124] Mix graphene, acrylate copolymer, bentonite and absolute ethanol, put the mixed solution into a disperser and stir for 20 minutes, the disperser speed is 800rpm; then use a horizontal sand mill to grind the solution to a particle size of less than 10 μm , to obtain A solution.

[0125] Step 3): Prepare B solution:

[0126] Mix solution A and low volatilization rate solvent at a ratio of 100:10, the low volatilization rate solvent is diethylene glycol butyl ether, then put the mixed solution of A solution and low volatilization rate solvent into a disperser and stir for 20 minutes, disperse The rotating speed of machine is 800rpm, obtains B solution.

[0127] Step 4): use the distillation equipment with condensing device to distill the B solution, set the dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com