Graphene quantum dot composite membrane for urban sewage purification treatment as well as preparation method

A graphene quantum dot, purification technology, applied in osmosis/dialysis water/sewage treatment, sterilization/microdynamic water/sewage treatment, chemical instruments and methods, etc., can solve the problem of irreversible membrane flux and easy to breed bacteria , low water flux, etc., to achieve the effect of long service life, avoiding secondary pollution and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

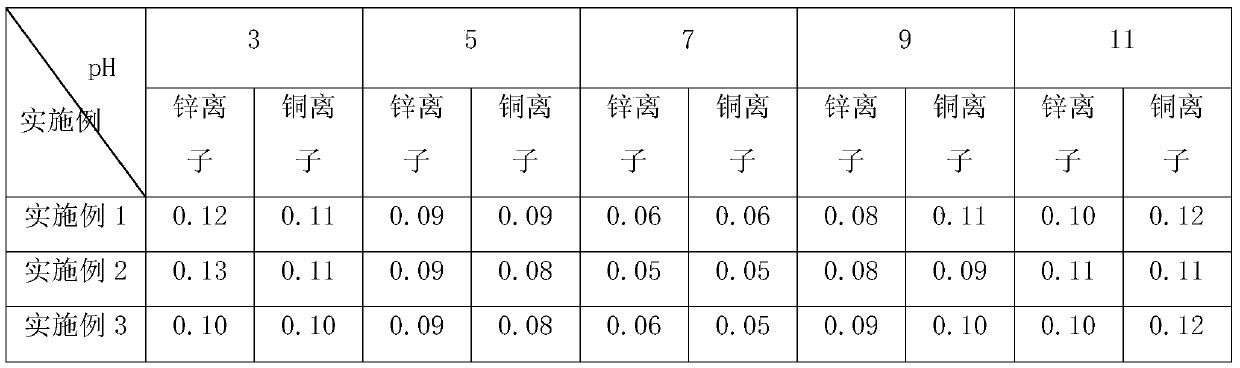

Examples

Embodiment 1

[0027] Embodiment 1: Composite membrane preparation one:

[0028] The base film of this embodiment is polyethylene film, the polyethylene film has a pore diameter of 50-60 nm, a thickness of about 1 mm, and a porosity of about 70%.

[0029] Before preparing the composite membrane, the basement membrane was pretreated, and poly-4-styrenesulfonic acid-maleic acid sodium salt was dissolved in deionized water to prepare a 25wt% soaking solution, and the basement membrane was placed in the soaking solution, and then soaked at 60 Heated in a water bath at ℃ for 1 hour, took out the basement film, ventilated in hot air at 30°C for 15 minutes, took it out, and air-dried naturally to obtain the pretreated basement film. The scale inhibitor is loaded on the basement membrane, which can prevent fouling and clogging of the composite membrane during the deposition process.

[0030] Graphene oxide preparation: slowly add 400ml of strong acid mixed with 98wt% concentrated sulfuric acid and ...

Embodiment 2

[0034] Embodiment 2: Composite membrane two

[0035] A polyethersulfone membrane is selected as the base membrane in this embodiment. The polyethersulfone membrane has a pore diameter of 60-70 nm, a thickness of about 1.5 mm, and a porosity of about 73%.

[0036] Before preparing the composite membrane, the basement membrane was pretreated, and poly-4-styrenesulfonic acid-maleic acid sodium salt was dissolved in deionized water to prepare a 25wt% soaking solution, and the basement membrane was placed in the soaking solution, and then soaked at 60 Heated in a water bath at ℃ for 1 hour, took out the basement film, ventilated in hot air at 30°C for 15 minutes, took it out, and air-dried naturally to obtain the pretreated basement film.

[0037] Graphene oxide preparation: slowly add 300ml of strong acid mixed with 98wt% concentrated sulfuric acid and 85wt% concentrated phosphoric acid according to the ratio of volume ratio = 9:1 to 5g graphite, then place it in a water bath and ...

Embodiment 3

[0041] Embodiment 3: Composite membrane three

[0042] The base membrane of this embodiment is a polyethersulfone membrane, the polyethersulfone membrane has a pore diameter of 60-70 nm, a thickness of about 2 mm, and a porosity of about 75%.

[0043] Before preparing the composite membrane, the basement membrane was pretreated, and poly-4-styrenesulfonic acid-maleic acid sodium salt was dissolved in deionized water to prepare a 25wt% soaking solution, and the basement membrane was placed in the soaking solution, and then soaked at 60 Heated in a water bath at ℃ for 1 hour, took out the basement film, ventilated in hot air at 30°C for 15 minutes, took it out, and air-dried naturally to obtain the pretreated basement film.

[0044] Graphene oxide preparation: slowly add 400ml of strong acid mixed with 98wt% concentrated sulfuric acid and 85wt% concentrated phosphoric acid according to the ratio of volume ratio = 9:1 to 8g graphite, then place it in a water bath and heat it to 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com