Method for preparing sodium alginate-polymethacryloyloxyethyl trimethylammonium chloride organic flocculant

A technology of polymethacryloyloxyethyltrimethylammonium chloride and methacryloyloxyethyltrimethylammonium chloride, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/ Sludge/sewage treatment and other directions can solve the problems of complex modification steps, small application range, poor water solubility, etc., and achieve the effect of obvious adsorption and bridging effect, good flocculation effect, and improved activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation of simulated surface water in the embodiment:

[0029] (1) Weigh 1.0 g of humic acid and 0.4 g of sodium hydroxide, dissolve with about 800 mL of deionized water and stir for 1 hour, and finally set the volume to 1 L to obtain humic acid stock solution;

[0030] (2) Weigh 5 g of kaolin, add 1 L of deionized water to dissolve and stir for 1 h, pour into a graduated cylinder to settle for 20 min, take 800 mL of the upper layer, and obtain a kaolin stock solution;

[0031] (3) Prepare water samples with tap water and humic acid stock solution at a volume ratio of 100:1, and adjust the turbidity to 14.5-15.5 with kaolin stock solution.

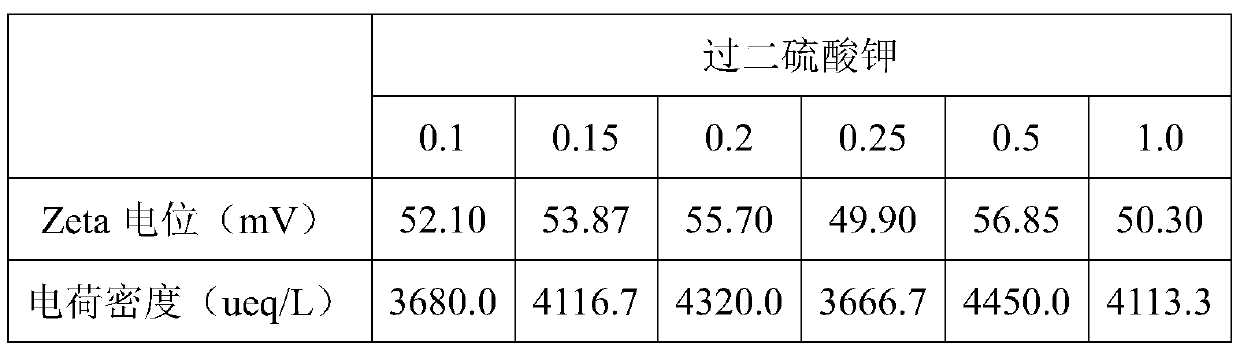

[0032] The water quality index of the simulated surface water is shown in Table 1 below, and the final treatment effect is represented by UV 254 The removal rate (%) is indicated.

[0033] Table 1 Water quality indicators of simulated water samples

[0034] pH UV 254

Embodiment 1

[0036] A kind of preparation method of sodium alginate-polymethacryloyloxyethyltrimethylammonium chloride organic flocculant, the steps are as follows:

[0037] (1) Take 1g of sodium alginate, add 100mL of deionized water, heat and dissolve to obtain sodium alginate solution;

[0038] (2) Heat the sodium alginate solution to 70°C, continuously feed high-flow nitrogen gas, and continue to stir for 30 minutes to make the sodium alginate solution full of bubbles to obtain a bubble-filled sodium alginate solution. The flow rate of high-flow nitrogen gas is: 200mL / min;

[0039] (3) Add 0.5g potassium peroxodisulfate to the sodium alginate solution full of bubbles to activate and react for 20min, then add 75wt% methacryloxyethyl trimethyl chloride dropwise in batches for three times Ammonium solution 20mL, continue to react at 70°C for 1h; the whole step is carried out under the protection of nitrogen;

[0040] (4) After the reaction, cool to room temperature, purify with acetone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com