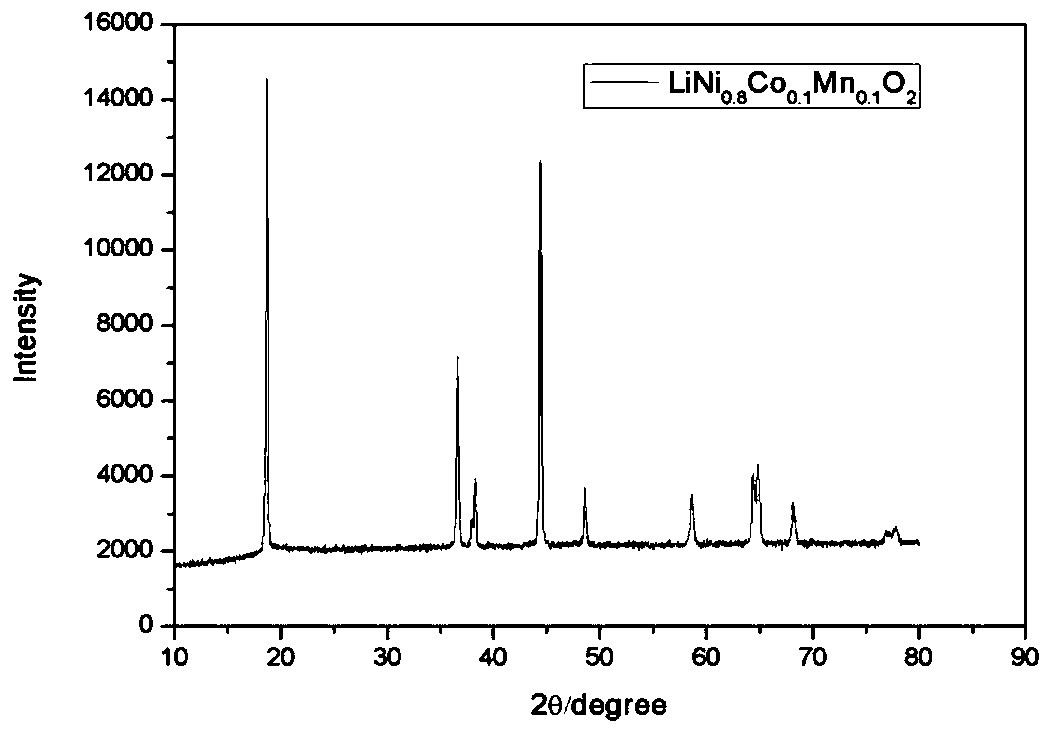

Method for improving electrochemical performance of high-nickel ternary positive electrode material by magnesium fluoride/sodium synergic modification

A technology of synergistic modification and positive electrode material, applied in the field of lithium-ion batteries, can solve the problems of poor material structure stability, decreased Coulombic efficiency, poor cycle performance, etc. Effect of Ion Diffusion Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0018] (1) Weigh 0.009mol of precursor powder, 0.00954mol of lithium hydroxide monohydrate and 0.00045mol of sodium carbonate, put the three in a beaker and add 20-30mL of absolute ethanol, ultrasonically shake for 30min and put them in an oven Dry at 80°C, grind in a mortar for 70 minutes, place the sample in a tube furnace, pre-sinter at 500°C for 5 hours in an oxygen atmosphere, calcinate at 750°C for 15 hours, and cool to room temperature with the furnace to obtain Li 0.9 Na 0.1 Ni 0.8 co 0.1 mn 0.1 o 2 Cathode material.

[0019] (2) After weighing 5% magnesium nitrate and ammonium fluoride in absolute ethanol, add 95% Li 0.9 Na 0.1 Ni 0.8 co 0.1 mn 0.1 o 2 Stir for 3 hours, dry and grind, add 2 drops of absolute ethanol at the right time during the grinding process, place the obtained mixed sample in a tube furnace, heat up to 500°C at a heating rate of 5°C / min under an argon atmosphere, and keep it for 4h, then cool down to At room temperature, the composite m...

Embodiment example 2

[0023] (1) Weigh 0.036mol of precursor powder, 0.03816mol of lithium hydroxide monohydrate and 0.0018mol of sodium carbonate, put the three in a beaker and add 80-120mL of absolute ethanol, ultrasonically shake for 30min and put them in an oven Dry at 80°C, grind in a mortar for 70 minutes, place the sample in a tube furnace, pre-sinter at 500°C for 5 hours in an oxygen atmosphere, calcinate at 750°C for 15 hours, and cool to room temperature with the furnace to obtain Li 0.9 Na 0.1 Ni 0.8 co 0.1 mn 0.1 o 2 Cathode material.

[0024] (2) After weighing 5% magnesium nitrate and ammonium fluoride in absolute ethanol, add 95% Li 0.9 Na 0.1 Ni 0.8 co 0.1 mn 0.1 o 2 Stir for 3 hours, dry and grind, add 2 drops of absolute ethanol at the right time during the grinding process, place the obtained mixed sample in a tube furnace, heat up to 500°C at a heating rate of 5°C / min under an argon atmosphere, and keep it for 4h, then cool down to At room temperature, the composite m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com