Compound NH4GaS2 and preparation method and application thereof

A compound and reaction technology, applied in the field of sulfide preparation, can solve the problems of high energy consumption and complex operation of the preparation method, and achieve the effects of low energy consumption, simple and easy method, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Weigh 1mmol of indium oxide and 20mmol of thiourea and mix them evenly, then add them into 20mL PTFE lining, then weigh 1.5g of oxalic acid and pour them into the PTFE lining, then seal the PTFE Lining, put the lining into the stainless steel jacket.

[0032] 2) Put the polytetrafluoroethylene lining and stainless steel jacket in step 1) into an oven, and react at 230 ° C for 72 hours. After the reaction is complete, wash the product with distilled water to remove unreacted soluble impurities and obtain white granular crystals, namely Compound NH 4 GaS 2 .

Embodiment 2

[0034] 1) Weigh 1mmol of indium oxide and 15mmol of thiourea and mix them evenly, then add them into 20mL PTFE lining, then weigh 2.0g of oxalic acid and pour them into the PTFE lining, then seal the PTFE Lining, put the lining into the stainless steel jacket.

[0035] 2) Put the polytetrafluoroethylene lining and stainless steel jacket in step 1) into an oven, and react at 240°C for 120h. After the reaction is complete, wash the product with distilled water to remove unreacted soluble impurities and obtain white granular crystals, namely Compound NH 4 GaS 2 .

Embodiment 3

[0037] 1) Weigh 1mmol of indium oxide and 30mmol of thiourea and mix them evenly, then add them into 20mL PTFE lining, then weigh 1.0g of oxalic acid and pour them into the PTFE lining, then seal the PTFE Lining, put the lining into the stainless steel jacket.

[0038]2) Put the polytetrafluoroethylene lining and stainless steel jacket in step 1) into an oven, and react at 230°C for 168h. After the reaction is complete, wash the product with distilled water to remove unreacted soluble impurities and obtain white granular crystals, namely Compound NH 4 GaS 2 .

[0039] 2. Compound NH 4 GaS 2 testing and verification

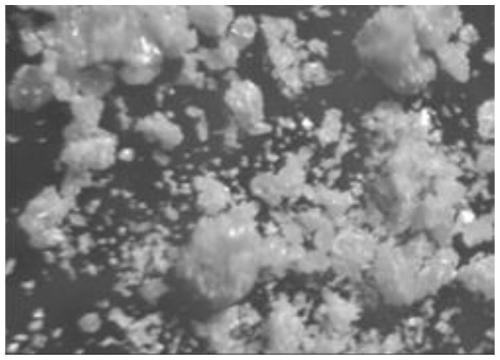

[0040] 1. The NH prepared in the above examples 4 GaS 2 The samples were observed under an optical microscope, and the results were as follows figure 1 shown.

[0041] It can be seen from the figure that when the sample is magnified 80 times, white granular crystals appear, and the large granular samples are stacked by smaller flake samples.

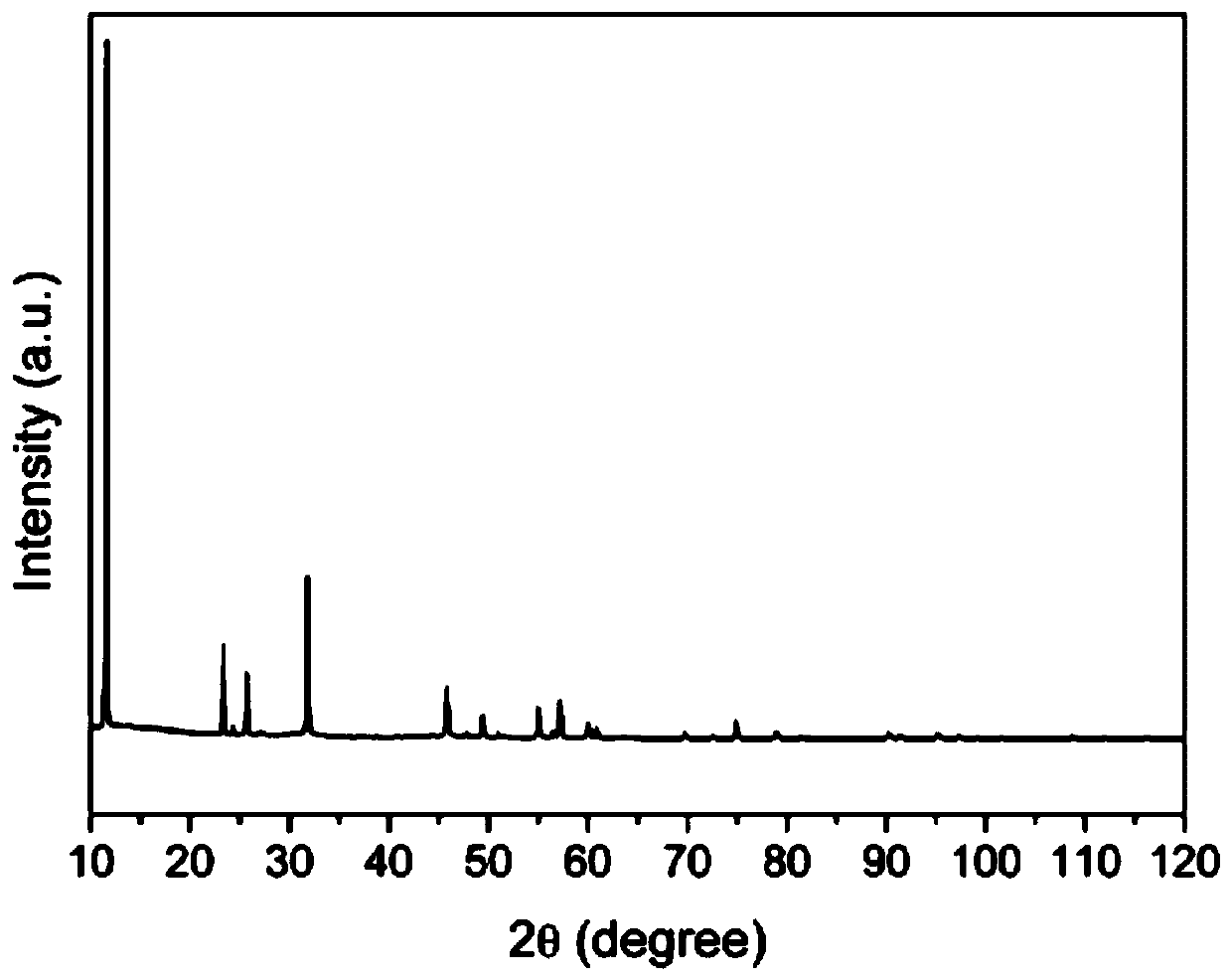

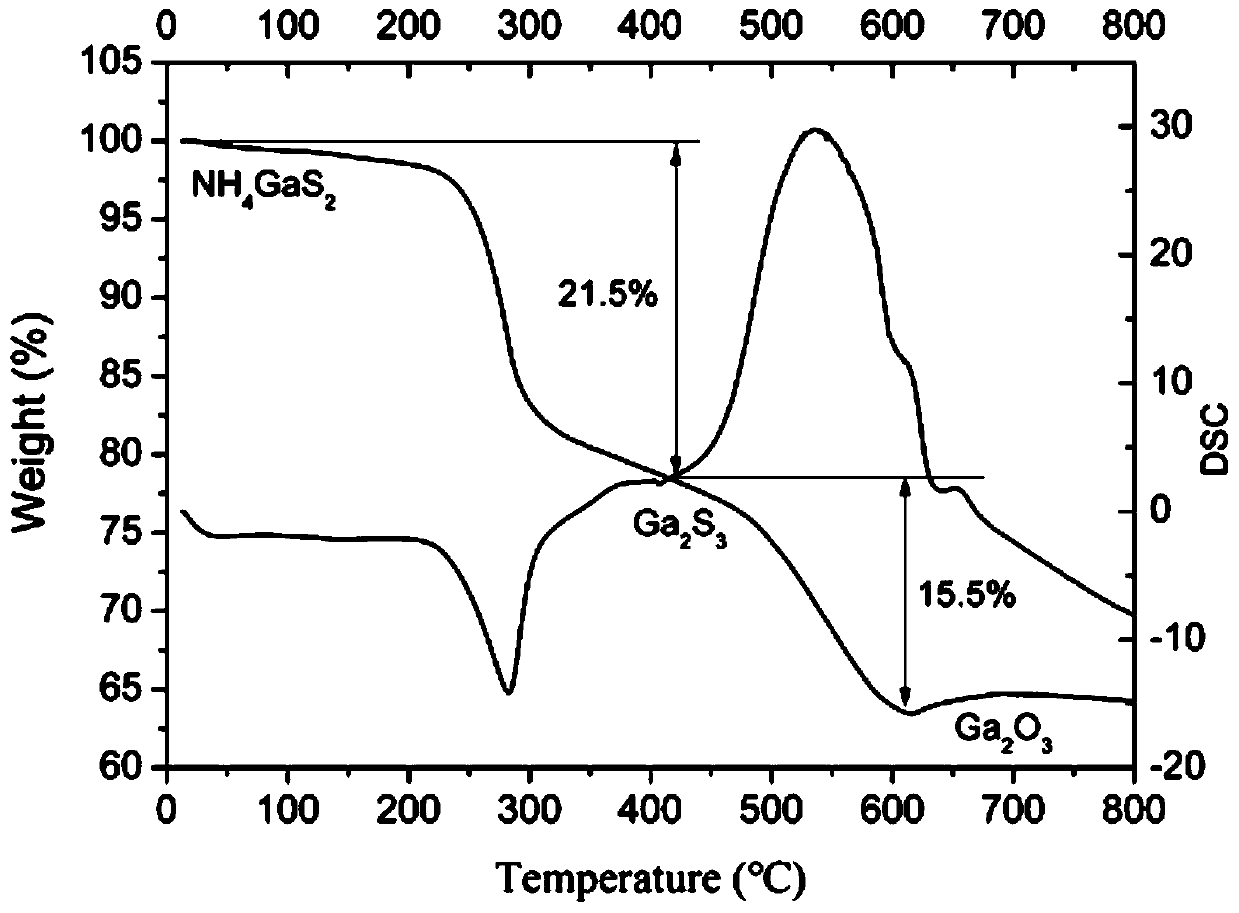

[0042] 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com