Preparation method of self-healing hydrogel

A hydrogel and self-healing technology is applied in the field of preparation of self-healing hydrogels and achieves the effects of easy control of conditions, simple operation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Dissolve 0.01g of dopamine in NaOH aqueous solution with pH=14, and pre-polymerize with stirring at room temperature for 10 minutes; then, add 0.25g of ammonium persulfate, 0.003g of N,N'-methylenebisacrylamide and 2.5g of acrylic acid monomer, fully After dissolving, add 20 μL of N,N,N',N'-tetramethylethylenediamine, stir evenly, and react in a water bath at 80°C for 1 hour to completely polymerize the acrylic acid monomer and dopamine, thereby obtaining , toughness and self-healing hydrogels.

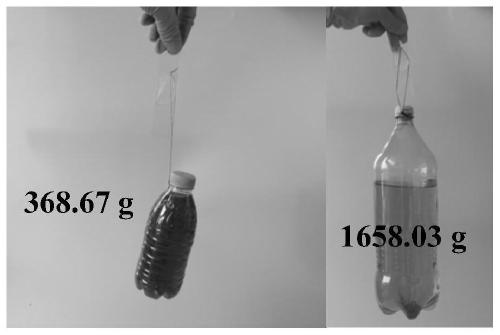

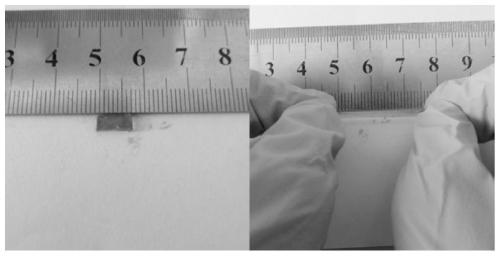

[0028] After determination, the self-healing hydrogel adhered glass sheet (adhesion area 3.5mm 2 ) can withstand objects with a mass of more than 1658g. The self-healing hydrogel can be bent in any direction without breaking, and quickly restores to its original shape after the bending force is released. Its tensile elongation exceeds 4.

Embodiment 2

[0030] Dissolve 0.09g of dopamine in KOH aqueous solution with pH = 10, pre-polymerize with stirring at room temperature for 10min, then add 0.3g of ammonium persulfate, 0.015g of N,N'-methylenebisacrylamide and 7g of acrylic acid monomer to make After fully dissolving, add 800μL N,N,N',N'-tetramethylethylenediamine, stir evenly, and react in a 90°C water bath for 0.5h, so that the acrylic acid monomer and dopamine are completely polymerized, so as to obtain Hydrogels with stretch, toughness and self-healing properties.

Embodiment 3

[0032] Dissolve 0.001 g of dopamine in Na at pH = 8 2 CO 3 In the aqueous solution, stir and pre-polymerize at room temperature for 50 minutes, then add 0.09g ammonium persulfate, 0.005g N,N'-methylenebisacrylamide and 1.5g acrylic acid monomer to fully dissolve, then add 15μL N,N, N',N'-Tetramethylethylenediamine, stirred evenly, and reacted in a water bath at 20°C for 80 hours to complete the polymerization of acrylic acid monomer and dopamine, so as to obtain water with adhesion, stretching, toughness and self-healing properties gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com