CMUT for gas sensing and preparation method thereof

A gas sensing and mixed gas technology, applied in the analysis of fluids using sound waves/ultrasonic waves/infrasonic waves, the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, measuring devices, etc. The influence of the transmission spectrum cannot be detected, the detection system is complex and huge, etc., to achieve the effect of broadening the detection range, improving the success rate and stability, and improving the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

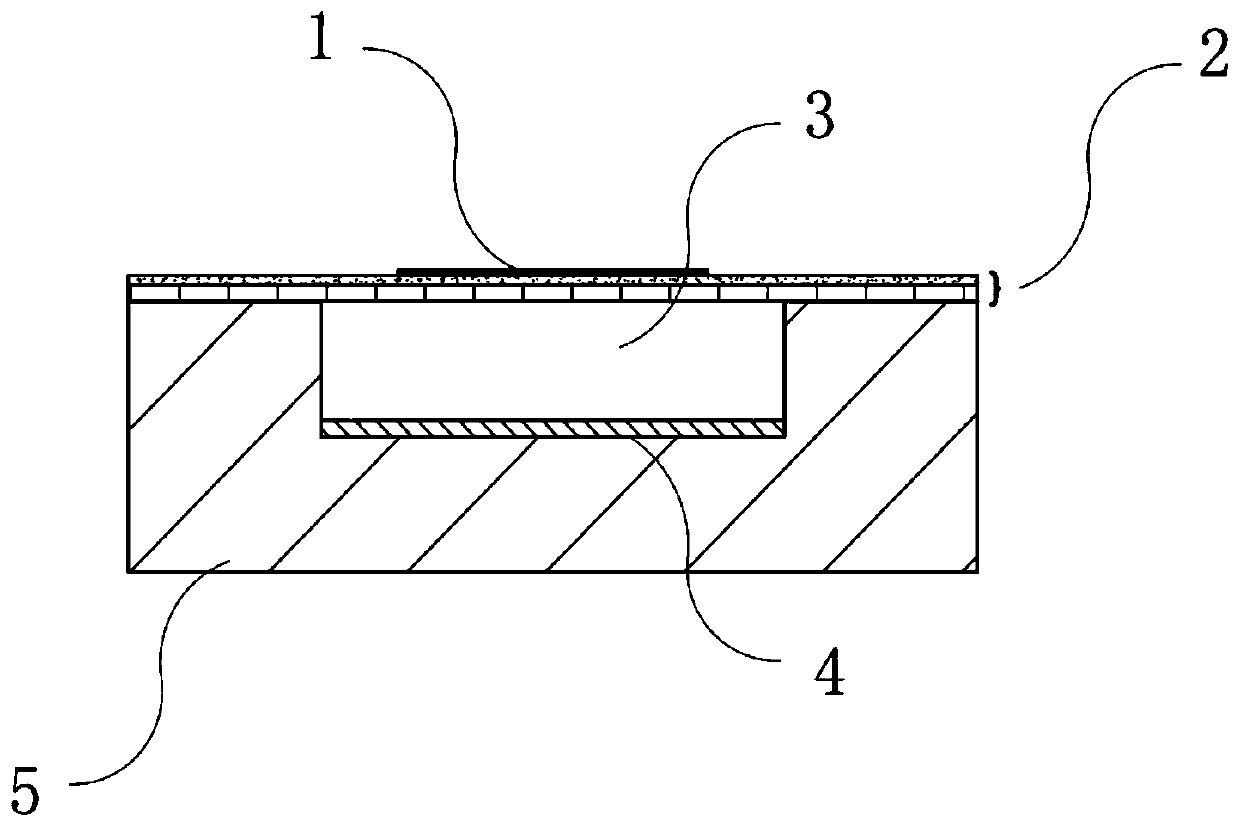

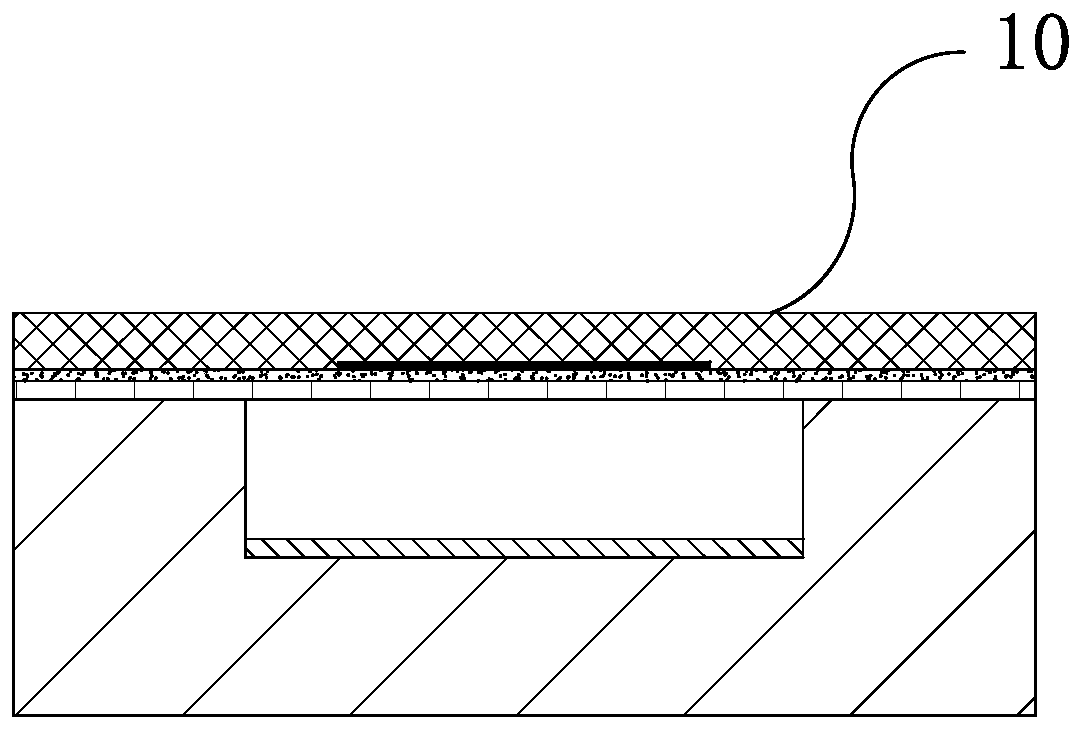

[0054] An embodiment of the present invention provides a capacitive ultrasonic sensor (CMUT), which is composed of several array elements, and each array element is composed of several sensitive units, see figure 1 , the structure of the single sensitive unit consists of an upper electrode 1 , a vibrating membrane 2 , an air or vacuum chamber 3 , a lower electrode 4 and a glass substrate 5 from top to bottom.

[0055] Air or vacuum cavity 3 is sandwiched between the vibrating film 2 and the glass substrate 5 to form a capacitor, and a DC voltage is applied to the electrodes at both ends of the CMUT in advance, so that an electrostatic field is formed between the upper electrode 1 and the lower electrode 4, and the vibrating film 2 Deformation occurs under the action of the electric field force, thereby forming a pre-tightening force in the vibrating membrane 2, and the vibrating membrane 2 is in a stable equilibrium state.

[0056] When the upper electrode 1 is grounded and an...

Embodiment 2

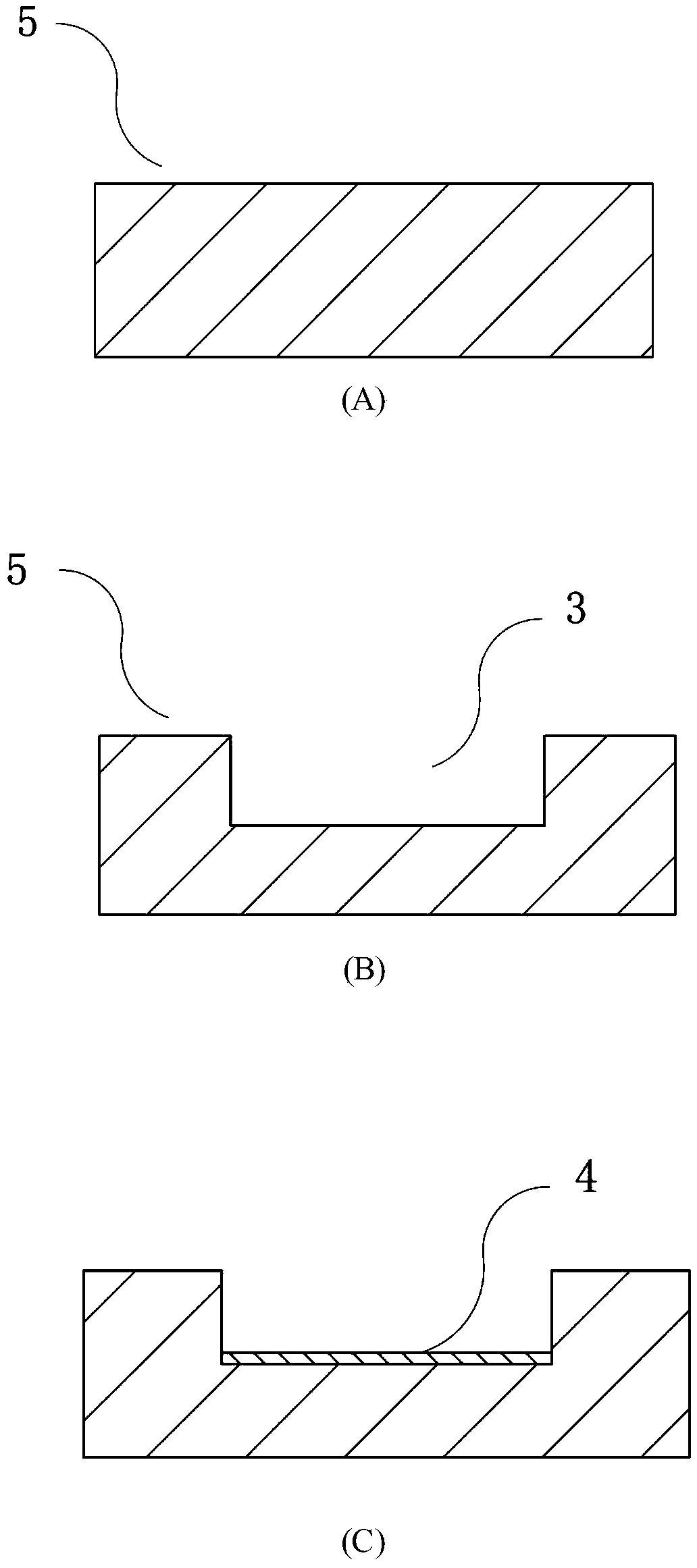

[0069] see image 3 , the embodiment of the present invention provides a method for preparing a CMUT applied to mixed gas analysis based on two types of sensing technologies, the preparation method comprising:

[0070] The SOI wafer and BF33 glass bonding technology used in the embodiment of the present invention overcomes the defect of through holes on the diaphragm caused by the surface silicon process for releasing the sacrificial layer, and at the same time avoids the problems caused by the whole piece of low-resistance silicon as the lower electrode. The parasitic capacitance, and the processing reliability of this process is high.

[0071] The process flow of SOI wafer and BF33 glass bonding is as follows:

[0072] Referring to Figure (A), the glass substrate 5 is prepared, and the glass substrate 5 is made of Schott glass BF33 specially used for anodic bonding, so as to form a high-strength bond with the device layer of the SOI wafer;

[0073] Referring to Figure (B),...

Embodiment 3

[0080] The resonance frequency of a single vibrating membrane 2 in the CMUT is:

[0081]

[0082] Among them, t is the thickness, r is the radius, E is the equivalent Young's modulus, m is the equivalent mass, and v is the equivalent Poisson's ratio.

[0083] When gas molecules with a mass of Δm are adsorbed on the surface of the vibrating membrane 2, the equivalent mass m of the vibrating membrane 2 e =m+Δm, resulting in a decrease in the resonant frequency. Adsorb and desorb a certain concentration of gas within a specific period of time. By detecting the change of the resonance frequency of each array element in the first working area in real time, collect and record the resonance peak pattern, and save it as a database after signal processing and algorithm processing, so as to realize Subsequent rapid identification of unknown gas mixtures.

[0084] The sensitivity of a single diaphragm 2 to mass is:

[0085]

[0086] Among them, ρ is the equivalent density of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com