Batch production process of canned stewed beef with hericium erinaceus

A production process and batch technology, applied in the field of batch production technology of monkey mushroom stewed beef

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

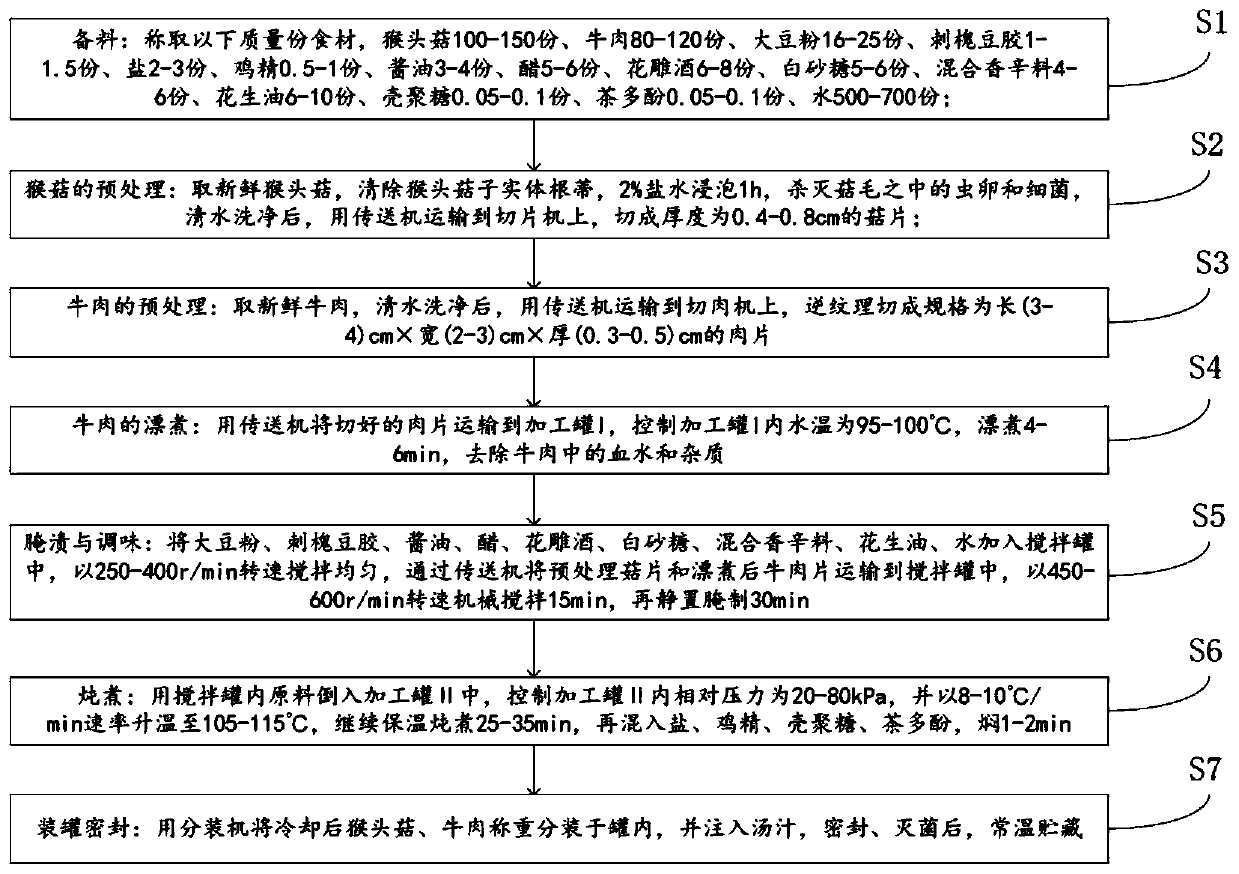

Method used

Image

Examples

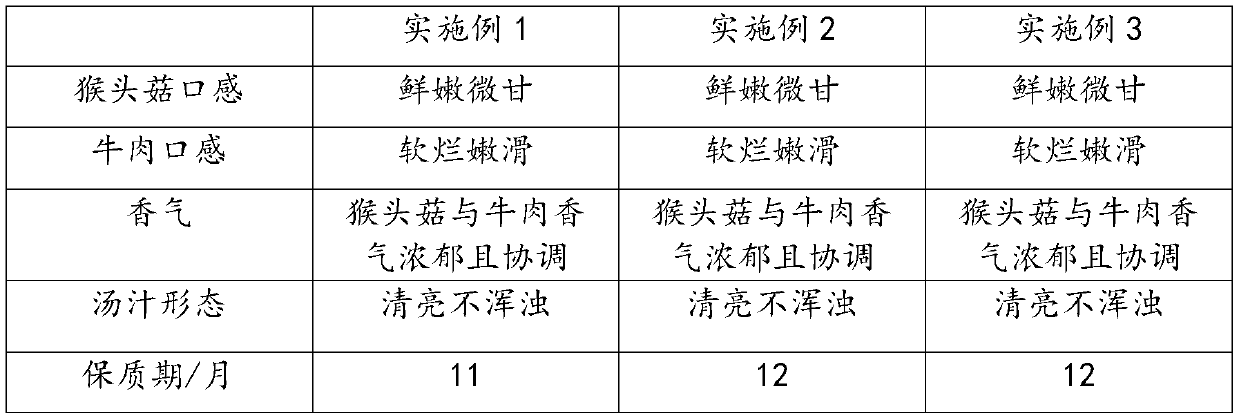

Embodiment 1

[0022] A batch production process of canned monkey mushroom stewed beef, comprising the following steps:

[0023] S1: Prepare ingredients: Weigh the following ingredients by weight, 100 parts of Hericium erinaceus, 80 parts of beef, 16 parts of soybean powder, 1 part of locust bean gum, 2 parts of salt, 0.5 parts of chicken essence, 3 parts of soy sauce, 5 parts of vinegar, Huadiao wine 6 parts, 5 parts of white sugar, 4 parts of mixed spices, 6 parts of peanut oil, 0.05 parts of chitosan, 0.05 parts of tea polyphenols, 500 parts of water;

[0024] Among them, the mixed spices include the following components by mass: 8 parts of garlic, 6 parts of ginger, 6 parts of green onion, 3 parts of pepper, 8 parts of pepper, 3 parts of pepper, 2 parts of star anise, 1 part of tangerine peel, 0.6 part of cumin, perilla 1 part of leaf, 0.6 part of mint, 1 part of passion grass, 0.4 part of lemongrass;

[0025] S2: Pretreatment of Hericium erinaceus: Take fresh Hericium erinaceus, remove...

Embodiment 2

[0032] A batch production process of canned monkey mushroom stewed beef, comprising the following steps:

[0033] S1: Prepare ingredients: Weigh the following ingredients by weight, 125 parts of monkey mushroom, 100 parts of beef, 20 parts of soybean flour, 1.3 parts of locust bean gum, 2.5 parts of salt, 0.8 parts of chicken essence, 3.5 parts of soy sauce, 5.5 parts of vinegar, 7 parts of Huadiao wine 5.5 parts of white sugar, 5 parts of mixed spices, 8 parts of peanut oil, 0.08 parts of chitosan, 0.08 parts of tea polyphenols, 600 parts of water;

[0034] Among them, the mixed spices include the following components by mass: 9 parts of garlic, 7 parts of ginger, 7 parts of green onion, 3.5 parts of pepper, 10 parts of pepper, 3.5 parts of pepper, 2.5 parts of star anise, 1.5 parts of tangerine peel, 0.8 part of fennel, perilla 1.5 parts of leaves, 0.8 parts of mint, 1.5 parts of passion grass, 0.5 parts of lemongrass;

[0035] S2: Pretreatment of Hericium erinaceus: Take f...

Embodiment 3

[0042] A batch production process of canned monkey mushroom stewed beef, comprising the following steps:

[0043]S1: Prepare ingredients: Weigh the following ingredients by weight, 150 parts of Hericium erinaceus, 120 parts of beef, 25 parts of soybean flour, 1.5 parts of locust bean gum, 3 parts of salt, 1 part of chicken essence, 4 parts of soy sauce, 6 parts of vinegar, Huadiao wine 8 parts, 6 parts of white sugar, 6 parts of mixed spices, 10 parts of peanut oil, 0.1 part of chitosan, 0.1 part of tea polyphenols, 700 parts of water;

[0044] Among them, the mixed spices include the following components by mass: 10 parts of garlic, 8 parts of ginger, 8 parts of green onion, 4 parts of pepper, 12 parts of pepper, 4 parts of pepper, 3 parts of star anise, 2 parts of tangerine peel, 1 part of cumin, perilla 2 parts of leaves, 1 part of mint, 2 parts of passion grass, 0.6 parts of lemongrass;

[0045] S2: Pretreatment of Hericium erinaceus: Take fresh Hericium erinaceus, remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com