Preparation of monolithic catalyst and application method thereof

A monolithic catalyst and photocatalyst technology, applied in the preparation of organic compounds, carbon-based compounds, chemical instruments and methods, etc., can solve the problems of poor product selectivity, low conversion rate, mismatching reduction potential, etc. Conditions are easy to control, high-efficiency magnetic induction heating, conducive to the effect of light-to-heat conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

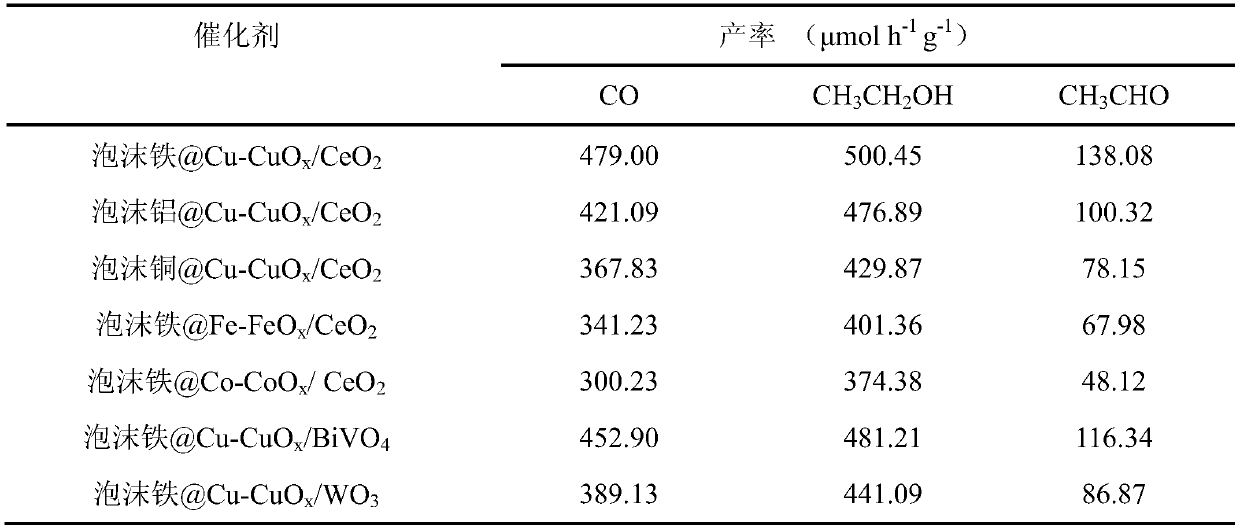

[0021] The invention discloses a method for preparing a monolithic catalyst. The catalyst uses metal foam materials such as iron foam, aluminum foam, and copper foam as carriers, and the CeO 2 、BiVO 4 、WO 3 The photocatalytic material is loaded on the surface of the metal foam, and then the Fe-FeO x , Cu-CuO x , Ni-NiO x 、Co-CoO x The co-catalyst is loaded on the surface of the above-mentioned catalytic material to prepare a monolithic catalyst. The specific operation steps are as follows:

[0022] Step 1: Preparation of photocatalytic material: Dissolve glacial acetic acid in absolute ethanol solvent at room temperature, stir for 20-40 minutes, and record it as solution A, dissolve cerium oxalate in absolute ethanol solvent, and add solution A dropwise Among them, the mass ratios of the above components are respectively: the mass ratio of glacial acetic acid to absolute ethanol is 1:10-1:12, and the mass ratio of cerium oxalate to absolute ethanol is 1:5-1:10. After the...

Embodiment 1

[0030] Preparation of photocatalytic material: Dissolve 10mL of glacial acetic acid in 100mL of absolute ethanol solvent at room temperature, stir for 30min, and record it as solution A, dissolve 10g of cerium oxalate in 100ml of absolute ethanol solvent, and add it dropwise to A Solution, continue to stir for 6 hours after the dropwise addition, and then place it in a dark place and seal it for 24 hours to obtain a uniform and stable CeO 2 Sol.

[0031] Other conditions remain the same, only the added metal salt precursor solution (BiVO 4 The precursors are bismuth nitrate and ammonium metavanadate, WO 3 The precursor is sodium tungstate), and different metal oxides can be obtained.

Embodiment 2

[0033] Preparation of metal foam material photocatalyst: The foam iron material was ultrasonically washed with absolute ethanol for 20 min, then washed with deionized water for 3 times, dried at room temperature and put into the prepared CeO 2 Immerse in the sol for 12 minutes, then take it out slowly by magnetic separation, filter off the excess sol, let it dry at room temperature for 12 hours, and finally bake it in a muffle furnace at 500°C for 60 minutes to prepare foamed iron-based CeO 2 catalyst of light.

[0034] Other conditions remain unchanged, only the added foam material carrier is changed, and the foamed iron-based photocatalyst, the foamed aluminum-based photocatalyst, and the foamed copper-based photocatalyst can be obtained respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com