Comprehensive treatment system and method of sludge

A technology of disposal system and disposal method, applied in dewatering/drying/concentrating sludge treatment, pyrolysis treatment sludge, by-product vaporization, etc. Sludge treatment methods need to be improved and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

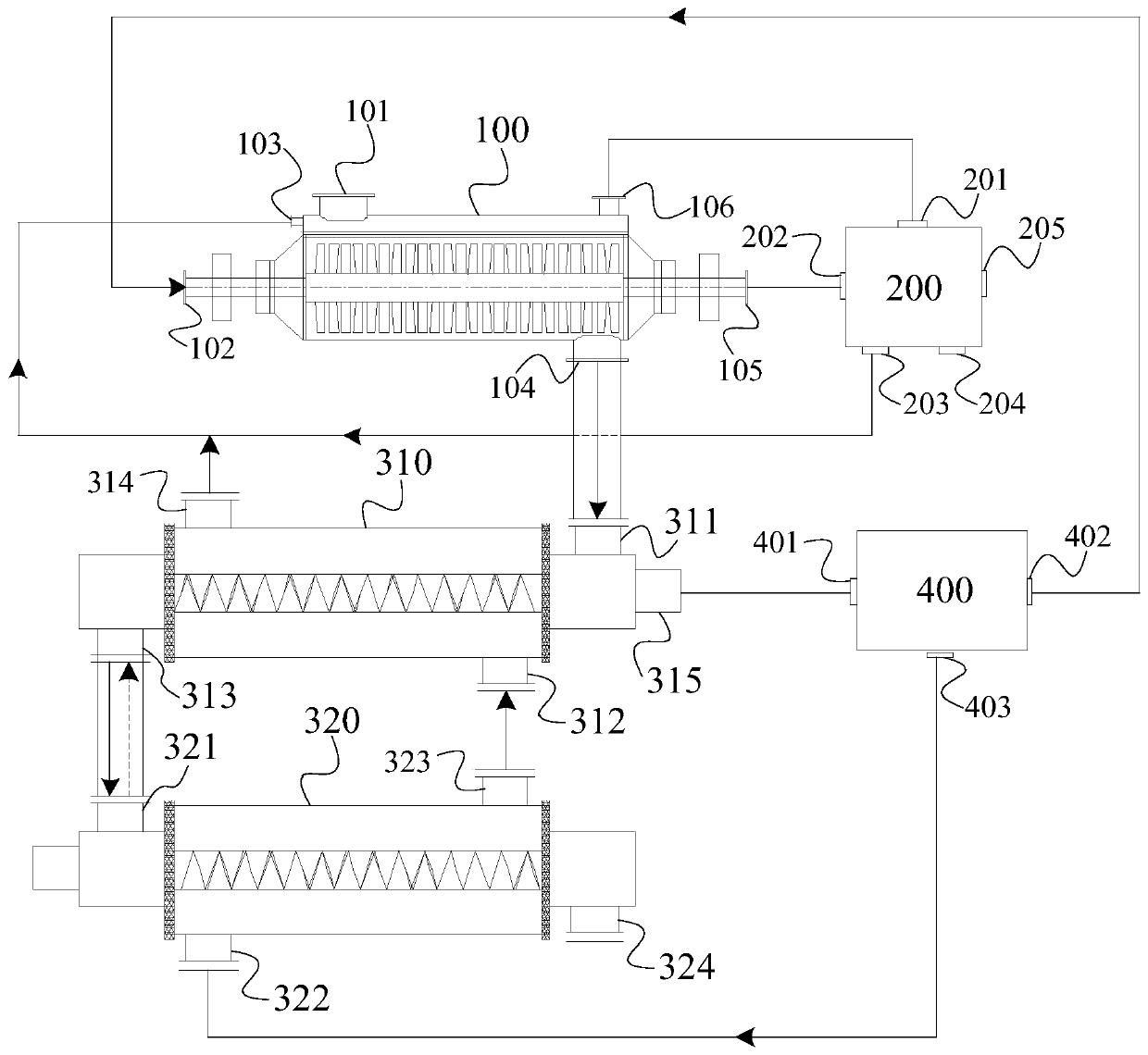

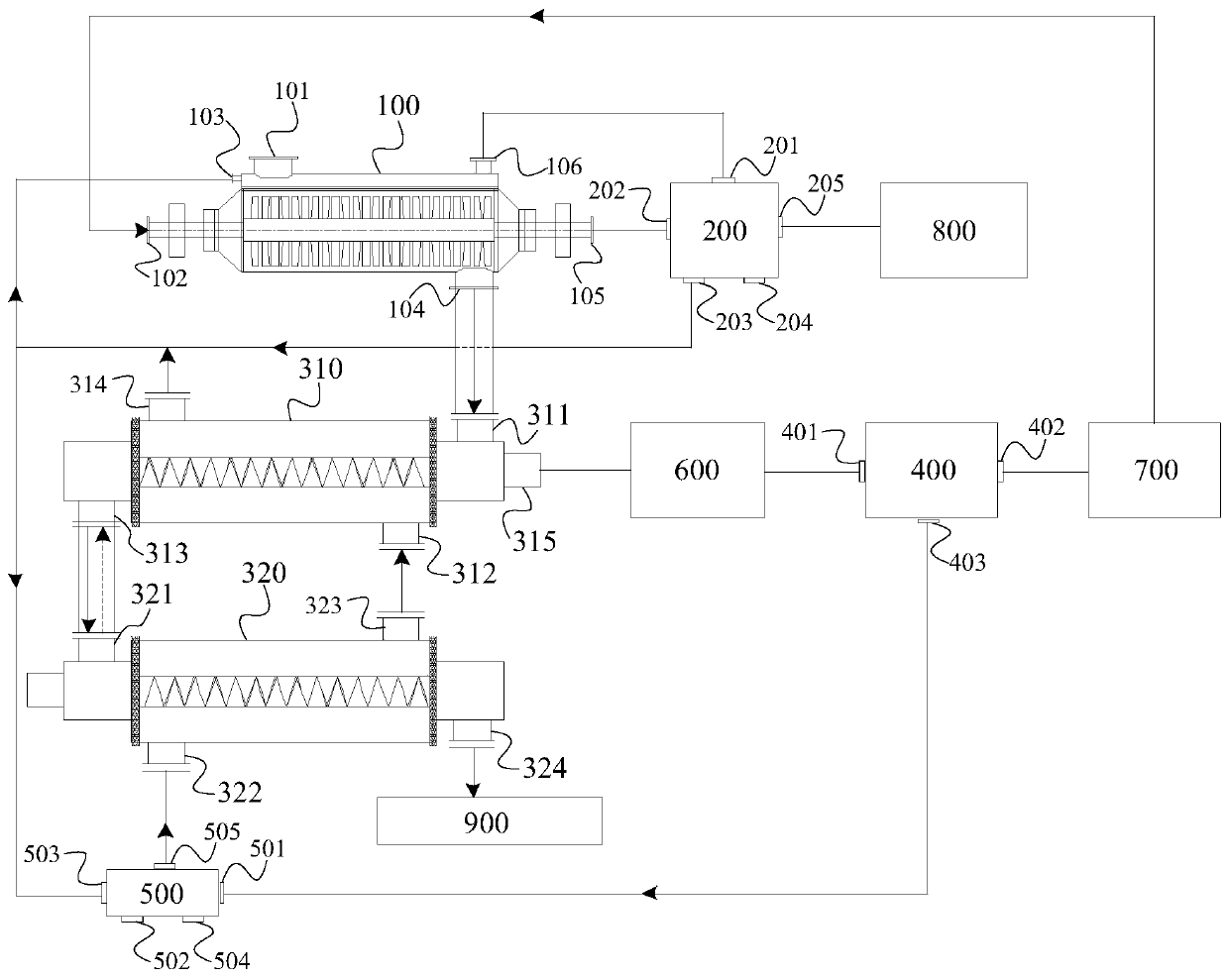

Image

Examples

Embodiment

[0100] The sludge with a moisture content of 80% is mixed with the oil-containing activated carbon output from the first dry distillation unit and sent to the paddle dryer, and dehydrated and dried for 60 minutes under the conditions of a water vapor temperature of 160°C and a furnace flue gas of 200°C. Obtain sludge with a moisture content of 50%; the sludge enters the first carbonization device through a vertical chute, performs dehydration and pre-carbonization at a flue gas temperature of 600°C (first carbonization treatment), and then enters the second carbonization device; the first carbonization device The steam generated in the first carbonization device, the pyrolysis gas introduced by the second carbonization device, and the non-condensable gas generated by partial sludge pyrolysis are mixed in the first carbonization device to form the second mixed gas, which makes the pyrolysis gas cool down, and tar is precipitated and adhered. On the surface of the sludge, it is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com