Vanadium lithium phosphate cathode material and preparation method thereof

A technology of lithium vanadium phosphate and positive electrode materials, which is applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems that cannot meet the requirements of extremely high power use, does not have the feasibility of large-scale production, and has poor safety. Guarantee the normal consumption of electrolyte, improve the effect of high-power charging and discharging, and high consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

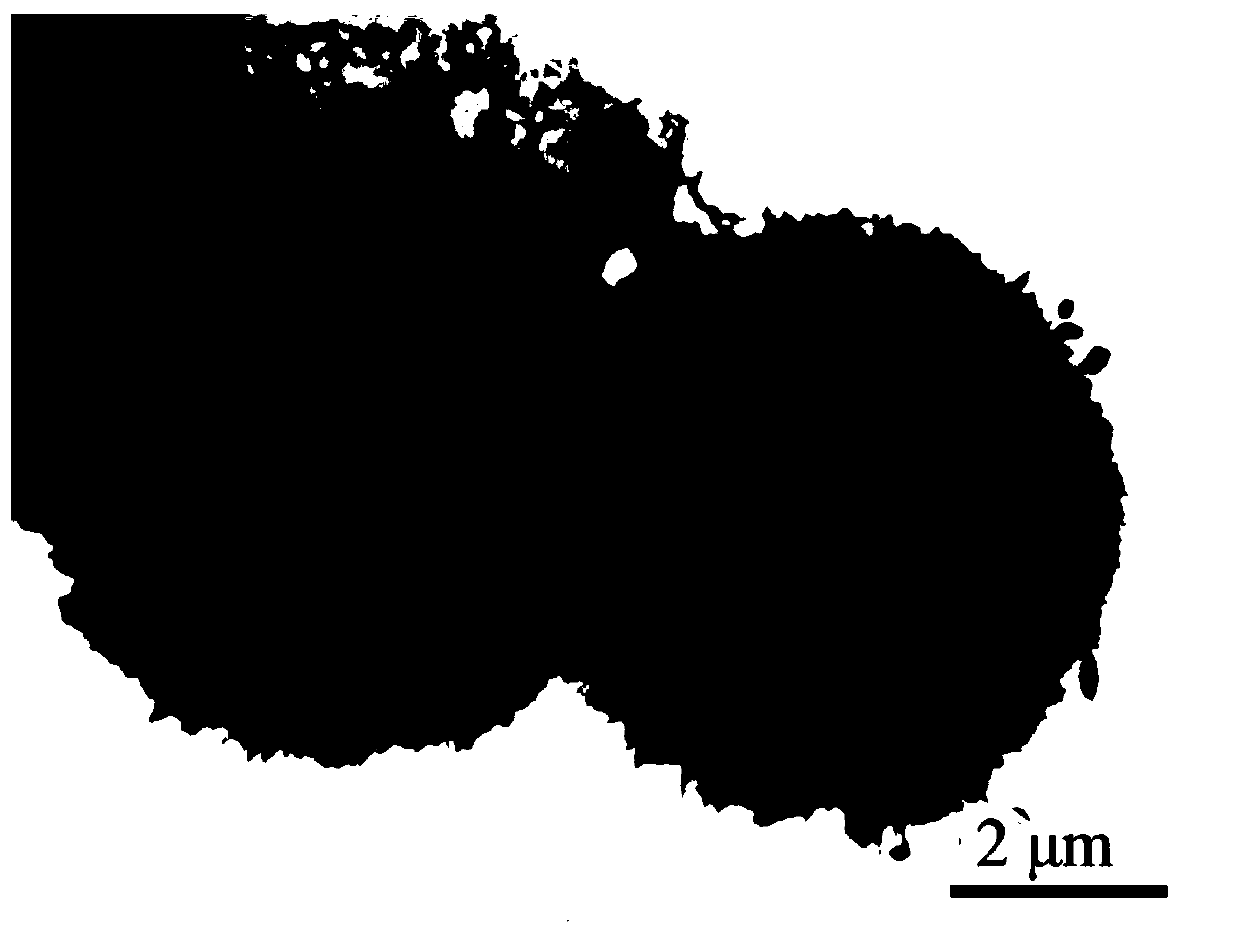

[0028] Embodiment 1: A lithium vanadium phosphate positive electrode material, the preparation method is as follows, first weigh 345.9 grams of 85% phosphoric acid, 222.3 grams of ammonium metavanadate, 5.3 grams of iron oxide, 126 grams of lithium hydroxide, and 35 grams of sucrose and 20g sodium dodecylbenzenesulfonate, the above raw materials are dispersed in 1760g of deionized water to form a suspension with a solid content of 30%; then the above suspension is added to the reactor and heated to 200 React at ℃ for 15 hours, after the reaction is completed and cooled to room temperature, wash, filter and dry to obtain the precursor powder of lithium vanadium phosphate; then weigh 9 grams of ammonium metavanadate and 450 grams of lithium vanadium phosphate precursor powder, and carry out the process in a high-speed disperser Mix well, then roast the above-mentioned raw materials at high temperature for 8 hours under the protection of nitrogen atmosphere, the roasting temperatu...

Embodiment 2

[0030] Embodiment 2: a kind of lithium vanadium phosphate cathode material, the preparation method is as follows, first weigh the lithium phosphate of 365.8g, the vanadyl oxalate of 477.7g, the sucrose of 126.5g and 84g triton, the above-mentioned raw materials are dispersed in 1581g of Prepare a suspension with a solid content of 40% in deionized water; then add the above suspension into a reaction kettle, heat it to 150°C under airtight conditions and react for 10 hours, after the reaction is completed and cooled to room temperature, wash, filter and dry to obtain vanadium phosphate Lithium precursor powder; then take by weighing 18 grams of ammonium metavanadate and 450 grams of lithium vanadium phosphate precursor powder, fully mix in a high-speed disperser, then above-mentioned raw materials are roasted at a high temperature for 5h under nitrogen atmosphere protection, and the roasting temperature is 600°C, and then cooled to room temperature to obtain lithium vanadium pho...

Embodiment 3

[0031] Embodiment 3: A lithium vanadium phosphate positive electrode material, the preparation method is as follows, first weigh 355g of ammonium dihydrogen phosphate, 181.1g of vanadium pentoxide, 0.4g of magnesium oxide, 201.3g of lithium acetate, 73.8g of poly Vinyl alcohol and 38g cetyltrimethylammonium bromide, the above raw materials are dispersed in 3400g of deionized water to form a suspension with a solid content of 20%; Heat to 250°C and react for 5 hours. After the reaction is completed and cool to room temperature, wash, filter and dry to obtain the precursor powder of lithium vanadium phosphate; then weigh 36 grams of ammonium metavanadate and 450 grams of lithium vanadium phosphate precursor powder, and Fully mixed in the machine, and then the above-mentioned raw materials were roasted at a high temperature for 2 hours under the protection of nitrogen atmosphere, the roasting temperature was 700 ° C, and then cooled to room temperature to obtain lithium vanadium p...

PUM

| Property | Measurement | Unit |

|---|---|---|

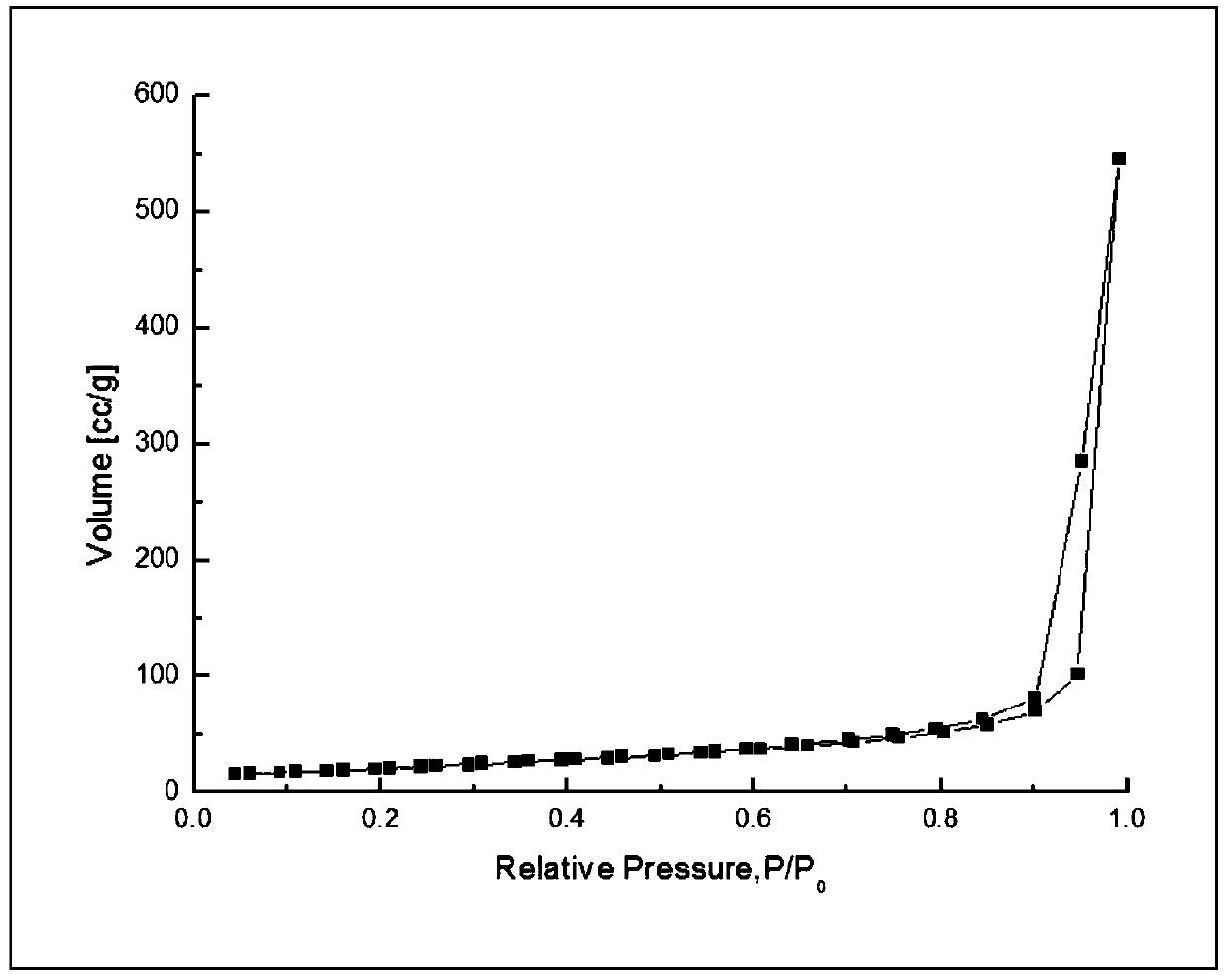

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com