Method for preparing protein inclusion body and recombinant human beta-neural growth factor

A technology for nerve growth factor and inclusion body, which is applied in the field of protein inclusion body and the preparation of recombinant human β-nerve growth factor, can solve the problems of low dilution and renaturation rate, unfavorable industrialized production, large renaturation volume, etc. , to achieve the effect of improving renaturation rate, reducing process cost and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of recombinant human β-nerve growth factor disclosed in some embodiments of the present invention comprises the following steps:

[0043] Step (1) performing chromatographic renaturation on the inclusion body of the recombinant human β-nerve growth factor precursor protein containing an enterokinase cleavage site to obtain the renatured precursor protein;

[0044] Step (2) performing enterokinase digestion on the renatured precursor protein to obtain an enzymatic hydrolysis product;

[0045] Step (3) separating and purifying the enzymatic hydrolysis product.

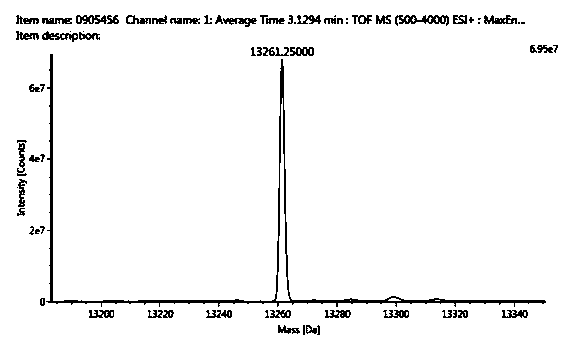

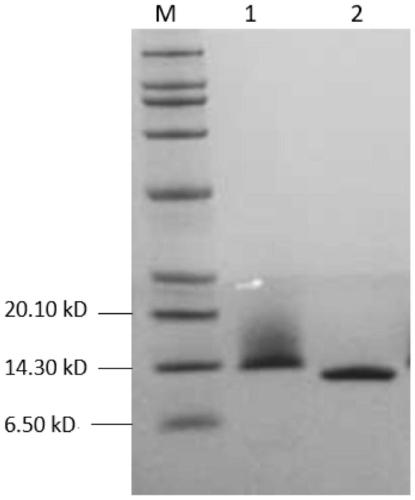

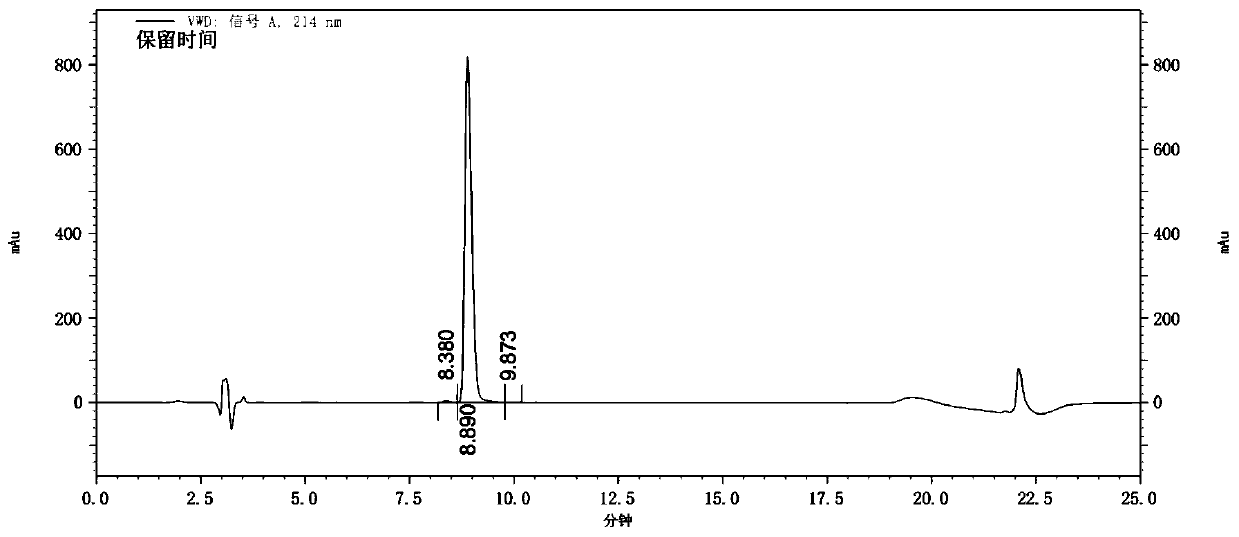

[0046]In the above examples, the chromatographic renaturation technology is applied to the renaturation of rhpro-NGF inclusion bodies. Compared with the traditional dilution renaturation method, it realizes renaturation under high concentration conditions, reduces the operation volume, and makes the renaturation process and purification process Completed under the same operating unit, the r...

Embodiment 1

[0074] Example 1: Construction of engineering bacteria expressing rhpro-NGF containing an enterokinase cleavage site

[0075] Referring to the codon preference of Escherichia coli, without changing the amino acid sequence, optimize the rhpro-NGF base sequence, and insert the base of the enterokinase recognition site DDDDK between the leader peptide and the mature peptide base sequence of the rhpro-NGF protein base sequence. Add the NdeI restriction site to the 5' end of the optimized base sequence, add the NotI restriction site to the 3' end, and add the stop codon sequence TAATAA between the 3' end of the target protein and the NotI restriction site, The base sequence shown in SEQ ID NO:1 was obtained, and the encoded amino acid sequence was shown in SEQ ID NO:2. The designed sequence is synthesized by chemical synthesis. Digest the synthetic sequence with NdeI / NotI, connect it with the expression plasmid pET-30a(+) cut with the same enzyme, transform Escherichia coli DH5α ...

Embodiment 2

[0080] Example 2: High-density culture of rhpro-NGF engineering bacteria and induced expression of target protein

[0081] Streak the rhpro-NGF engineered bacteria on LB plates (kan 100mg / L) and culture them in a constant temperature incubator at 37°C for about 16-18 hours until a single colony grows. Pick a single colony of engineered bacteria and inoculate in 20ml LB medium (kan 100mg / L), and culture at 37□, 230rpm for 8h. Transfer 0.1% to 250ml LB (kan 100mg / L), 1L Erlenmeyer flask, culture at 37°C, 230rpm for 13h. Four bottles were cultivated in parallel, 1000ml of bacterial solution was prepared, and 5% was inoculated into the medium of the upper tank of the fermenter NLF-2220L. Before inoculation, the pH was adjusted to 7.0 with ammonia water, and the temperature during the fermentation process was controlled at 36□. The pH value and dissolved oxygen of the culture medium are controlled by adding ammonia water and increasing the stirring speed and ventilation, and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com