Preparation method of titanium alloy material with good biocompatibility and antibacterial function coating

A biocompatibility, titanium alloy technology, applied in the direction of coating, metal material coating process, tissue regeneration, etc., can solve the problems of low deposition efficiency, lattice displacement, infection, etc., to achieve good biocompatibility, coating The effect of uniform layer and good crystallization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

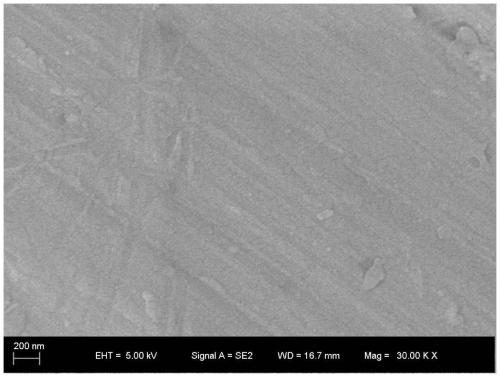

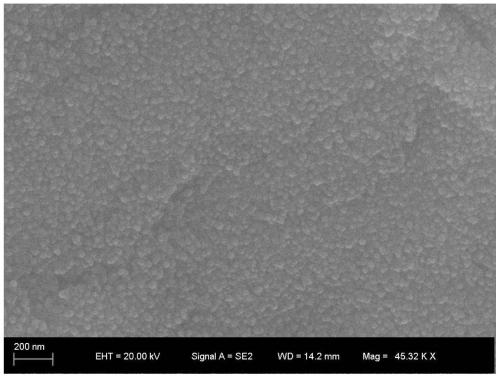

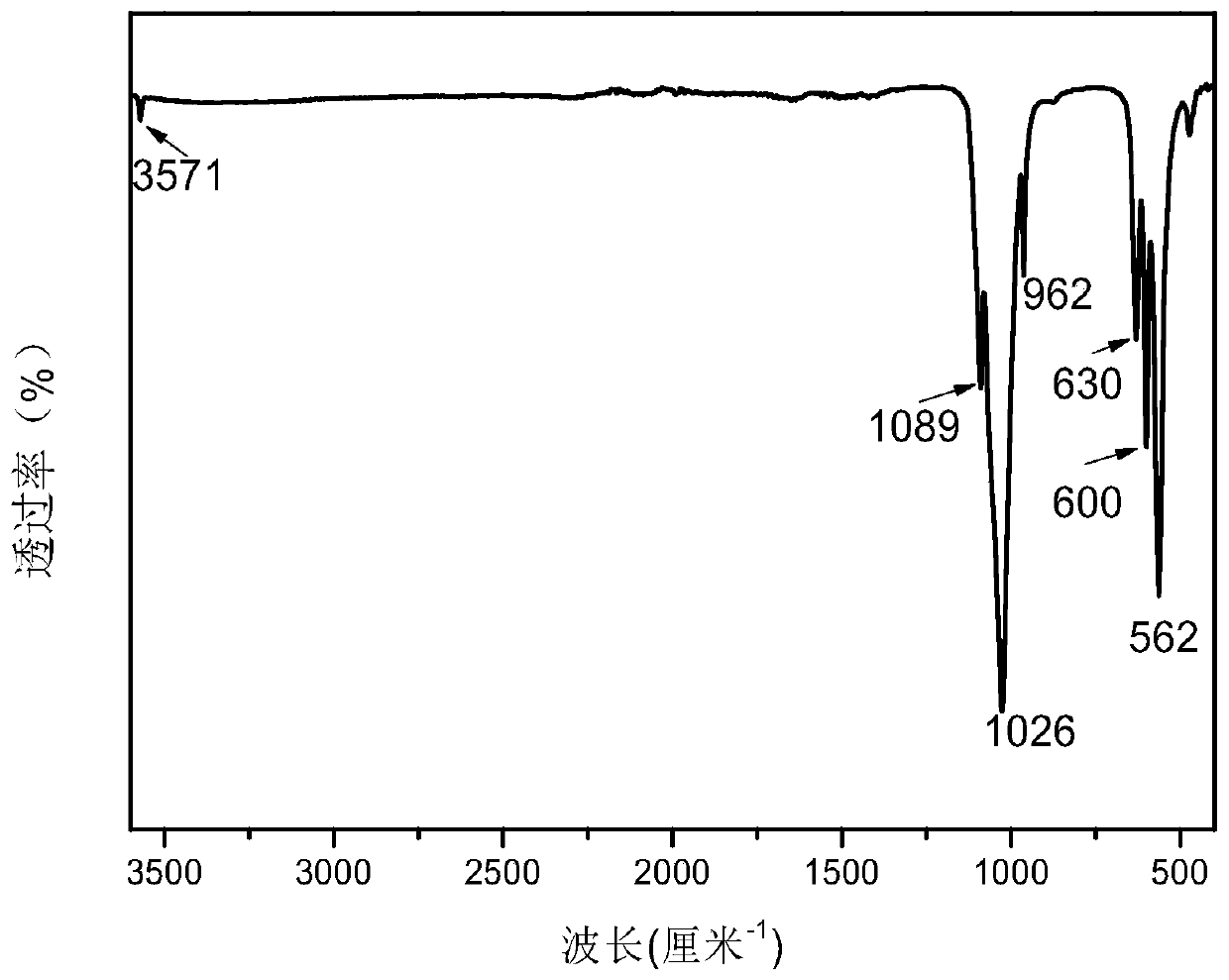

[0029] Dissolve 7.88g of calcium nitrate tetrahydrate and 2.64g of diammonium hydrogen phosphate in 30ml and 20ml of deionized water, respectively. The sanded material was first soaked in absolute ethanol for 10 min, then soaked in 2% hydrochloric acid for 1.5 h, then ultrasonically cleaned in deionized water, and finally dried at 100 °C. Under the condition of stirring, put the titanium alloy material and the calcium source solution in 1 into a closed reaction kettle. Add the phosphorus source solution into the reaction kettle, and adjust the pH of the solution to 10, and then react in an oven at 180°C for 24 hours. After the reaction is completed, the material is taken out and ultrasonically cleaned in deionized water, and then the material is placed in a 5 g / L levofloxacin-ethanol solution for 1 h, washed in phosphate buffered saline solution for 10 min in a shaker, and then dried in an air-dried oven at 80°C for 40 minutes to remove residual solvent and obtain good bioco...

Embodiment 2

[0042]Dissolve 78.8 g of calcium nitrate tetrahydrate and 24.5 g of diammonium hydrogen phosphate in 300 ml and 200 ml of deionized water, respectively. Sandpaper-polished materials were first soaked in absolute ethanol for 15 min, then soaked in 1% hydrochloric acid for 2 h, finally put in deionized water for cleaning and ultrasonication, and finally dried at 120 °C. Under the condition of stirring, put the titanium alloy material and the calcium source solution in 1 into the reaction kettle. Add the phosphorus source solution into the reaction kettle, adjust the pH of the solution to 11, and then react in an oven at 190°C for 30 h. After the reaction is completed, the material is taken out and ultrasonically cleaned in deionized water, and then the material is placed in a 5 g / L levofloxacin-ethanol solution for 1 h, washed with phosphate buffer in a shaker for 10 min, and then dried in an air-dried oven at 80°C for 40 min to remove residual solvents and obtain a good antib...

Embodiment 3

[0045] Dissolve 100g of calcium nitrate tetrahydrate and 34.95g of diammonium hydrogen phosphate in 500ml of deionized water respectively. Sandpaper-polished materials were first soaked in absolute ethanol for 5 min, then soaked in 1% hydrochloric acid for 1 h, finally put in deionized water for cleaning and ultrasonication, and finally dried at 85 °C. Under the condition of stirring, put the titanium alloy material and the calcium source solution in 1 into the reaction kettle. Add the phosphorus source solution into the reaction kettle, and adjust the pH of the solution to 9, and then react in an oven at 160°C for 18 h. After the reaction is completed, the material is taken out and ultrasonically cleaned in deionized water, and then the material is placed in a 5 g / L levofloxacin-ethanol solution for 1 h, washed with phosphate buffer in a shaker for 10 min, and then dried in an air-dried oven at 80°C for 40 min to remove residual solvents and obtain a good antibacterial and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com