Probiotics liposome and preparation method thereof

A technology of probiotics and liposomes, which is applied in the direction of liposome delivery, dairy products, milk preparations, etc., can solve problems such as no patent reports, and achieve improved stability and activity, stable system, increased survival rate and The effect of the number of colonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

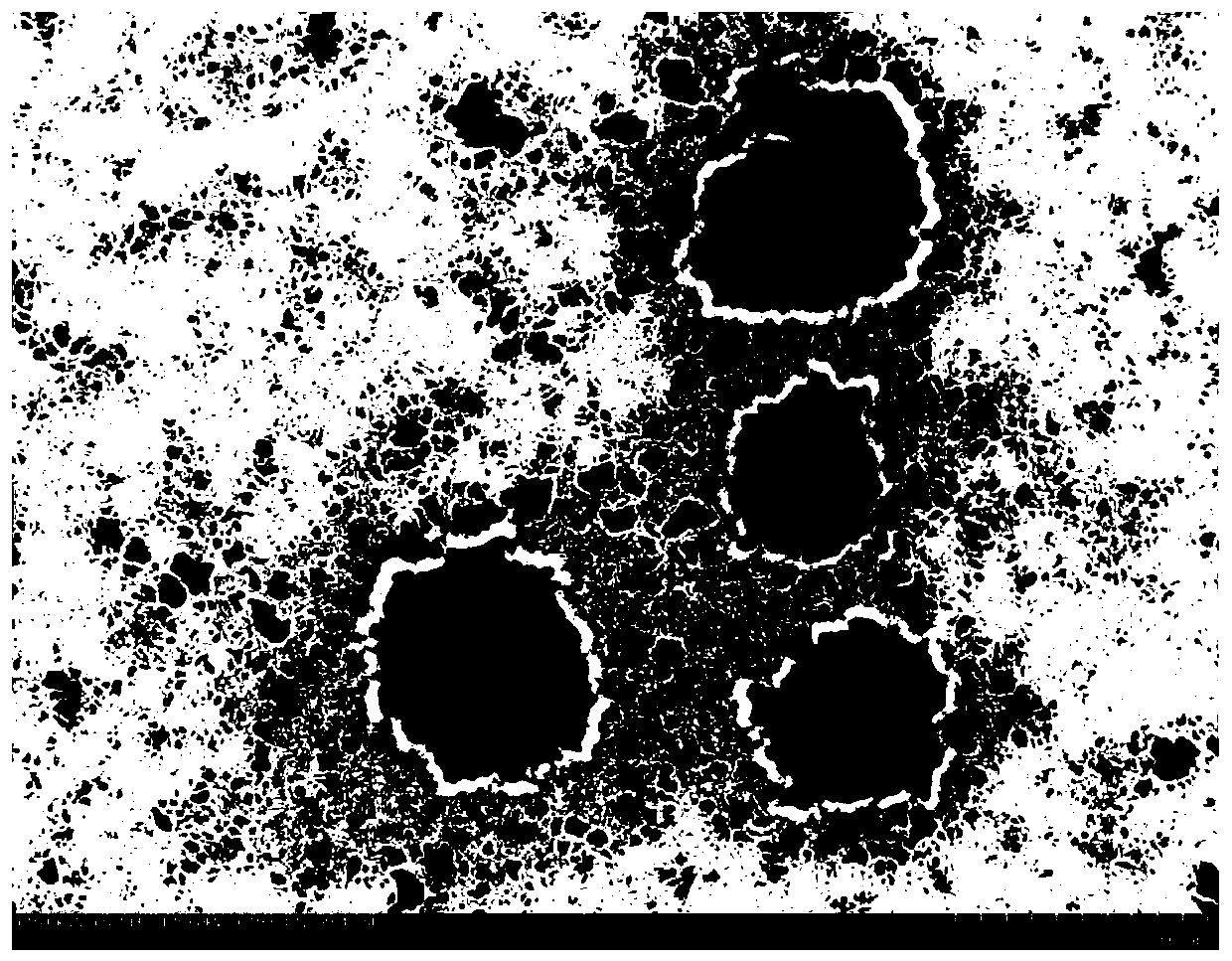

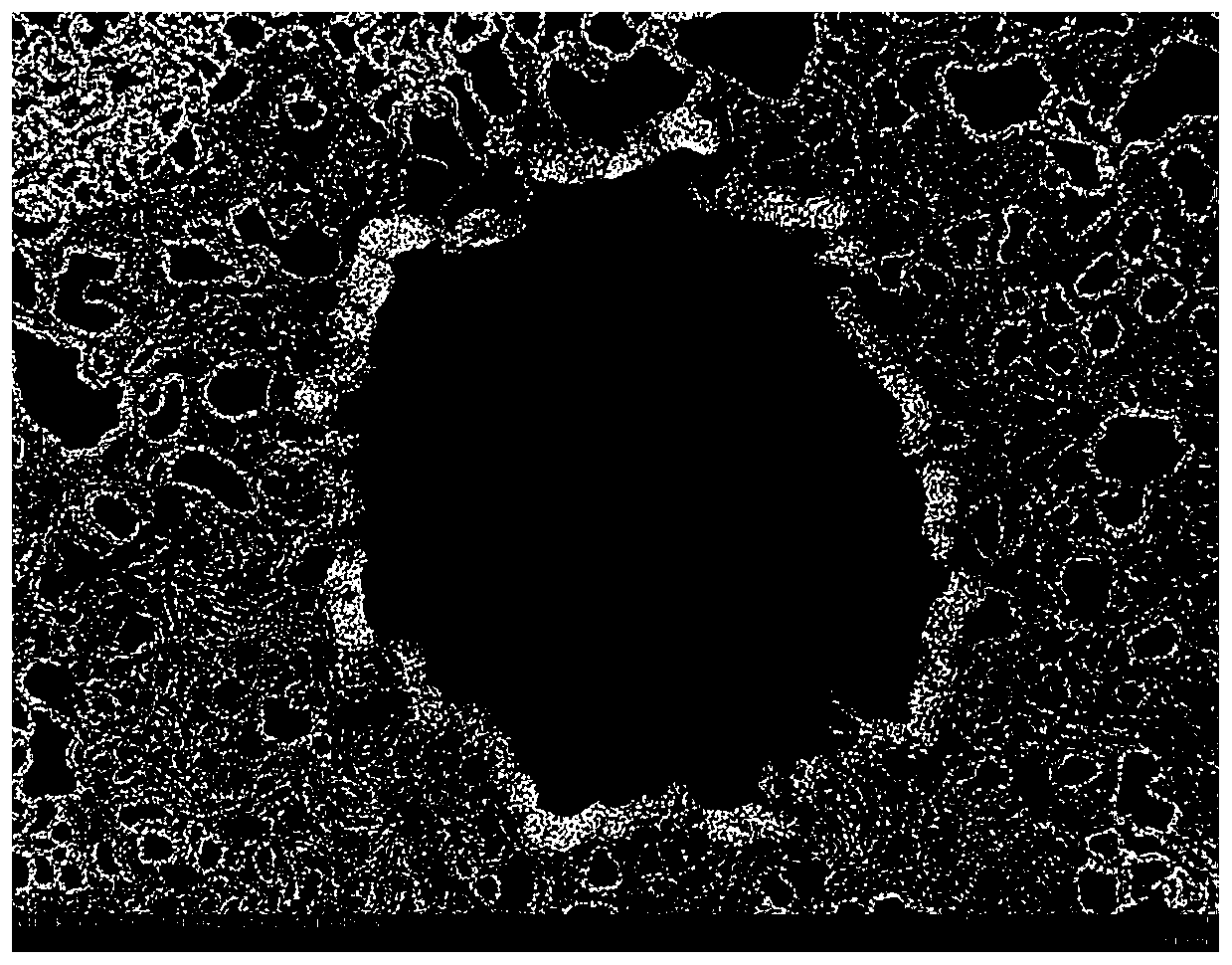

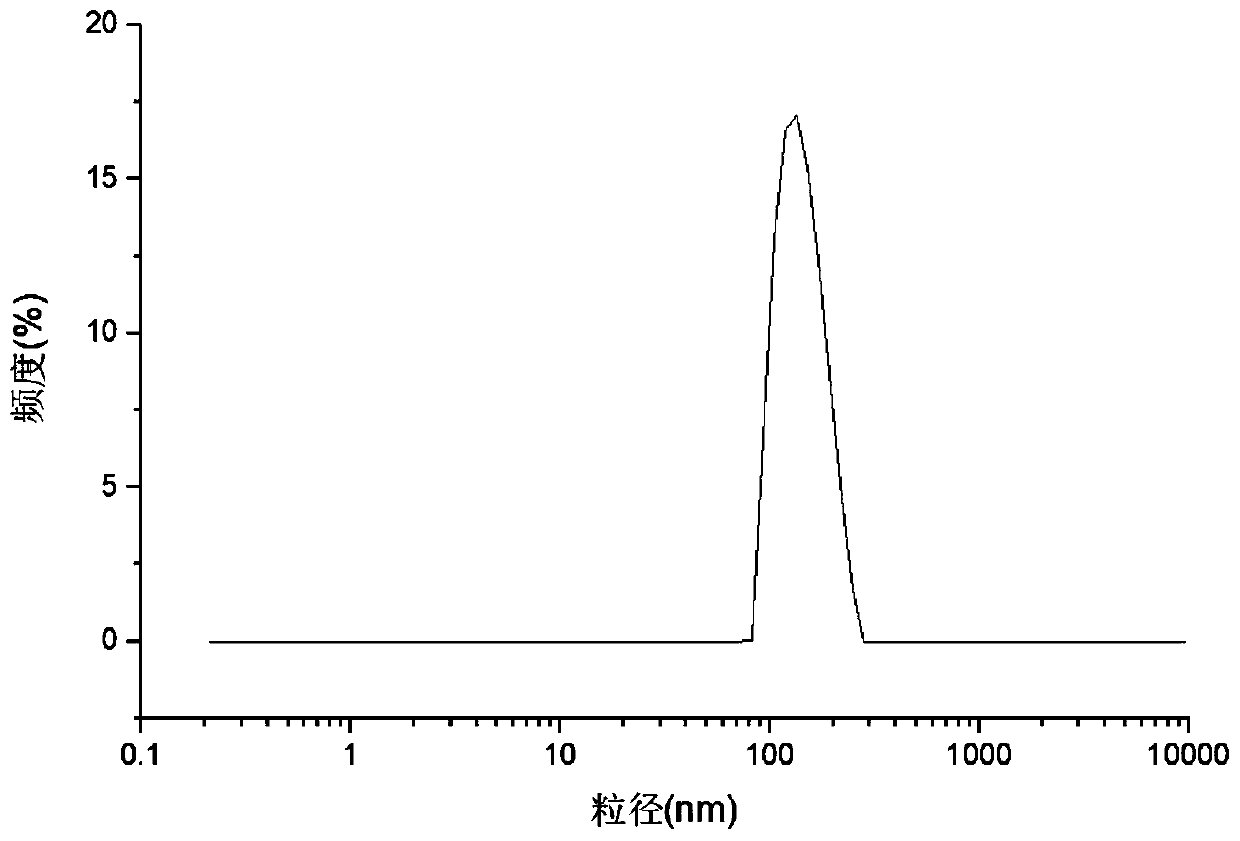

Image

Examples

Embodiment 1

[0038] (1) Take 140 mg of soybean lecithin and 23 mg of cholesterol required for making liposomes with a ten-thousandth balance, and place them in a rotary steamer;

[0039] (2) Measure 5 mL of chloroform and add it to the rotary steamer, shake it to fully dissolve soybean lecithin and cholesterol, and form a clear and transparent mixed solution 1;

[0040] (3) Place the rotary evaporating bottle with mixed solution 1 at 45° C. on a 150rmp rotary evaporator for 30 min under reduced pressure to remove chloroform and form a uniform transparent film on the wall of the bottle. The steaming bottle was placed in a vacuum drying oven to dry for 12 hours to remove residual chloroform;

[0041] (4) prepare pH=7.0 with ultrapure water, the phosphate buffer solution that mass fraction is 0.40%;

[0042] (5) Take 10mL of phosphate buffer solution and 17.5mg of probiotic freeze-dried powder respectively, put them in a centrifuge tube, mix well to obtain mixed solution 2, and preheat to 40...

Embodiment 2

[0047] (1) Weigh 150 mg of soybean lecithin and 25 mg of cholesterol required for making liposomes with a ten-thousandth balance, and place them in a rotary steamer;

[0048] (2) Measure 8 mL of chloroform and add it to the rotary steamer, and shake to fully dissolve the soybean lecithin and cholesterol to form a clear and transparent mixed solution 1;

[0049] (3) Place the rotary evaporating bottle with the above mixed solution 1 at 45° C. on a 100rmp rotary evaporator for 40 min under reduced pressure to remove chloroform and form a uniform transparent film on the bottle wall, and then The rotary evaporator was placed in a vacuum drying oven for 12 hours to remove residual chloroform;

[0050] (4) prepare pH=7.2 with ultrapure water, the phosphate buffer solution that mass fraction is 0.42%;

[0051] (5) Take 10mL of phosphate buffer solution and 15mg of probiotic freeze-dried powder and place them in a centrifuge tube, mix well to obtain a mixed solution 2, and preheat to...

Embodiment 3

[0056] (1) Weigh 160 mg of soybean lecithin and 20 mg of cholesterol for making liposomes with a ten-thousandth balance, and place them in a rotary steamer;

[0057] (2) Take another 10 mL of chloroform and add it to the rotary steamer, shake it to fully dissolve the soybean lecithin and cholesterol, and form a clear and transparent mixed solution 1;

[0058] (3) Place the rotary evaporating bottle with the above mixed solution 1 at 50° C. on a 50rmp rotary evaporator for 60 min under reduced pressure, remove chloroform, and form a uniform transparent film on the wall of the bottle, and then The rotary evaporator was placed in a vacuum drying oven for 12 hours to remove residual chloroform;

[0059] (4) prepare pH=7.5 with ultrapure water, the phosphate buffer solution that mass fraction is 0.45%;

[0060] (5) Take 10mL of phosphate buffer solution and 14mg of probiotic freeze-dried powder respectively and place them in a centrifuge tube, mix thoroughly to obtain a mixed solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com