A method for improving the efficiency of sludge anaerobic digestion while reducing the ecotoxicity of heavy metals

An anaerobic digestion and heavy metal technology, applied in the field of solid waste recycling, can solve problems such as low treatment efficiency, and achieve the effects of increasing methane accumulation, improving microbial activity, and reducing land use risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

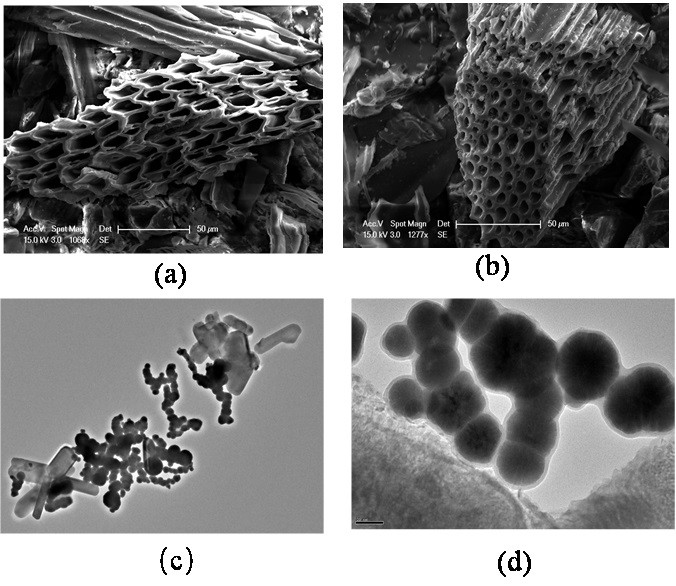

[0032] Embodiment: The specific steps of this embodiment are as follows: biochar pretreatment: under room temperature conditions, the original straw is first soaked in ZnCl 2 Activation in solution, straw raw material and ZnCl 2 The mass ratio is controlled to be 1:2; stirring and centrifuging (4000r min -1 ) and bake at (105±5)°C to constant weight. After drying, use a vacuum tube furnace to carbonize. Under the protection of nitrogen, it will be pyrolyzed at 550-580°C for 180 minutes, and the heating rate will be 20°C·min. -1 , carbonization time is 180min.

[0033] Wash with deionized water and dry at low temperature until constant weight. Soak 30g of pretreated biochar in 150mL of HCl solution with a concentration of 1.5mol / L for 24h, and then place it in a 600w WXJ-Ⅲ microwave digestion apparatus for further modification. The modified biochar material is dried at low temperature and ground through a 100-mesh sieve.

[0034] Preparation of biochar-supported zero-valen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com