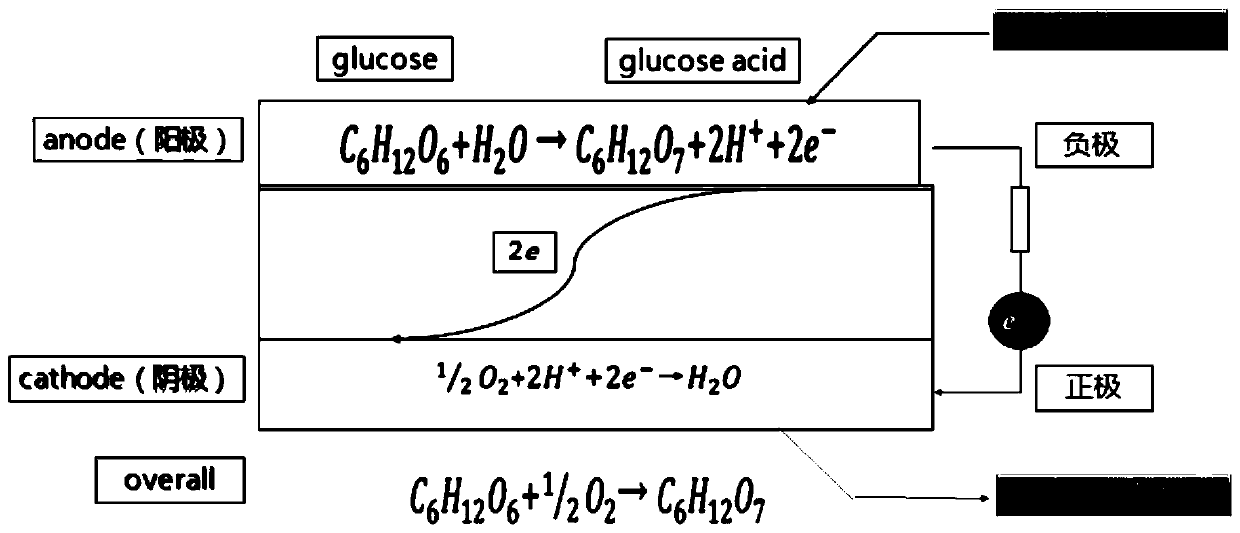

Fuel cell electrocatalytic porous gold electrode with sugar as raw material, preparation method thereof and application of fuel cell electrocatalytic porous gold electrode in artificial intelligence sensor

A technology of micro-fuel cells and gold electrodes, applied in battery electrodes, electrodes, electrotherapy, etc., can solve the problems of unstable enzyme electrodes, high prices, and obstacles to large-scale applications, and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing a negative electrode electrocatalytic porous gold electrode of a fuel cell using glucose carbohydrates as raw materials, comprising the following steps:

[0045] 1) Using nickel foam as the base material, electrodeposit gold-tin alloy;

[0046] 2) Removing metal tin to obtain a modified porous gold electrode. Further, step 1) uses nickel foam as the working electrode, and conducts electrodeposition in a gold-tin alloy solution to obtain a modified porous gold electrode.

[0047] Preferably, in step 1), the composition of the gold-tin alloy solution used for electrodeposition is: gold sulfite 10g / L-50g / L, tin methanesulfonate 10g / L-50g / L, citric acid 40g / L-90g / L, potassium pyrophosphate 50g / L~90g / L, potassium sulfate 10g / L~30g / L; further preferably, in step 1), the composition of described gold-tin alloy solution is: gold sulfite 20g / L ~40g / L, tin methanesulfonate 20g / L~40g / L, citric acid 50g / L~80g / L, potassium pyrophosphate 60g / L~80g / L, potassi...

Embodiment 1

[0057] Preparation of porous gold: nickel foam is used as the working electrode, platinum sheet is used as the counter electrode, and gold-tin alloy solution is used as the electroplating solution. 2 Electrodeposition at current density for 20 min. The composition of the gold-tin plating solution is 20 g / L of gold sulfite, 30 g / L of tin methanesulfonate, 50 g / L of citric acid, 70 g / L of potassium pyrophosphate, and 20 g / L of potassium sulfate.

[0058] After electroplating, wash it with deionized water, then dry it in the air, then soak the electrode in the etching solution 20M potassium hydroxide solution, take it out and soak it in deionized water for 30 minutes, air dry naturally or heat it in an oven at 60°C to obtain foam Nickel modified porous gold.

Embodiment 2

[0060] Preparation of porous gold: use nickel foam as the working electrode, platinum sheet as the counter electrode, and gold-tin alloy solution as the plating solution. 2 Electrodeposition at current density for 20 min. The gold-tin plating solution is composed of gold sulfite 30g / L, tin methanesulfonate 20g / L, citric acid 80g / L, potassium pyrophosphate 70g / L, and potassium sulfate 20g / L.

[0061] After electroplating, wash with deionized water, then dry in the air, then soak the electrode in 10M potassium hydroxide solution of etching solution, take it out and soak in deionized water for 30min, air dry naturally or heat and dry in an oven at 80°C to obtain foam Nickel modified porous gold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com