a bi 2 o 2 co 3 /bi 2 the w 6 :yb 3+ 、er 3+ Photocatalyst and its preparation method and application

A photocatalyst, -er3 technology, applied in the field of preparation of nano photocatalytic materials, can solve the problems of small specific surface area, unfavorable electron transfer and storage, easy recombination of photogenerated electrons and holes, and achieve good application prospects, simple process, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 Pure Bi 2 o 2 CO 3 preparation of

[0035] One, the preparation method is as follows:

[0036] Weigh 0.485g bismuth nitrate pentahydrate and dissolve it in a mixed solvent formed by 24ml ethylene glycol and 6ml deionized water, stir at room temperature until clarified to obtain a precursor solution; transfer the precursor solution to a 100ml hydrothermal reaction kettle, and The hydrothermal kettle was placed in an oven at 180°C for solvothermal reaction for 12 hours. After the reaction was completed, the oven was closed and the hydrothermal kettle was cooled to room temperature to obtain a precipitate. Take the precipitate in a centrifuge tube, centrifuge and wash three times with deionized water and absolute ethanol, and dry at 80°C for 12 hours to obtain pure Bi 2 o 2 CO 3 sample.

[0037] 2. Test results

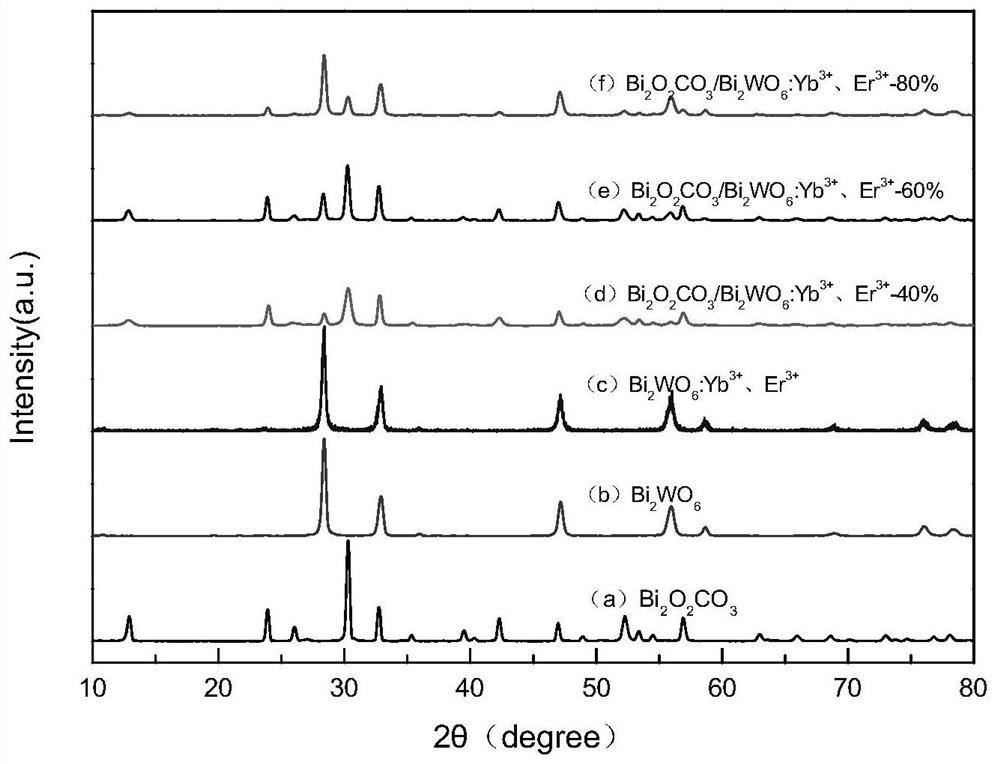

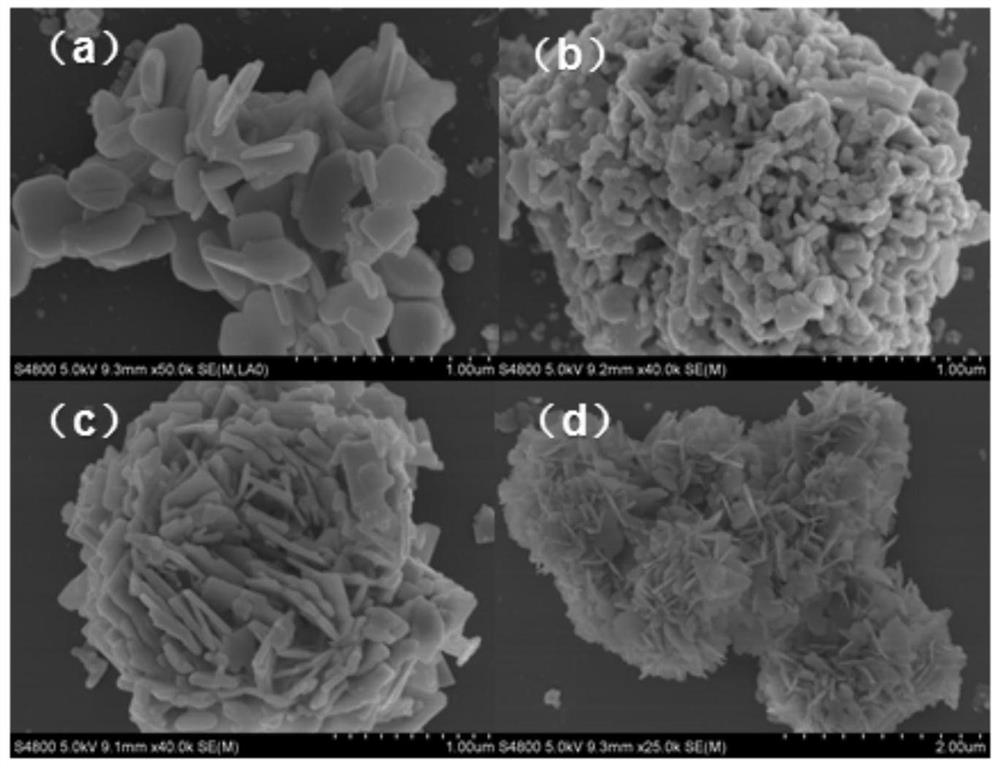

[0038] figure 1 The curve in (a) is pure Bi 2 o 2 CO 3 XRD detection of samples. It can be seen from the figure that the pure Bi 2 o ...

Embodiment 2

[0040] Embodiment 2 Pure Bi 2 WO 6 preparation of

[0041] One, the preparation method is as follows:

[0042] Dissolve 2mmol of bismuth nitrate pentahydrate in 10ml (0.4mol / L) of dilute nitric acid to obtain a clear and transparent A solution; dissolve 1mmol of sodium tungstate dihydrate in 20ml of deionized water to obtain a clear and transparent B solution. Add solution A to solution B dropwise, adjust the pH of the mixed solution to 1 with 0.4 mol / L dilute nitric acid, and stir at room temperature for 60 minutes to obtain a white suspension. The reaction system was transferred to a polytetrafluoroethylene stainless steel reaction kettle, solvothermally reacted at 160°C for 20 hours, then cooled naturally, the precipitate was washed with deionized water and absolute ethanol for 3 times and centrifuged, and dried in an oven at 80°C Afterwards, it was calcined in a muffle furnace at 550 °C for 4 h to obtain Bi 2 WO 6 Nano powder.

[0043] 2. Test results

[0044] figu...

Embodiment 3

[0046] Example 3 Bi 2 WO 6 : Yb 3+ 、Er 3+ preparation of

[0047] One, the preparation method is as follows:

[0048] (1) Dissolve 0.3mmol ytterbium oxide and 0.1mmol erbium oxide in 10mL (0.4mol / L) dilute nitric acid, heat and stir, and obtain Yb 3+ -Er 3+ solution.

[0049] (2) Dissolve 2mmol of bismuth nitrate pentahydrate in 10ml of dilute nitric acid to obtain a clear and transparent A solution; dissolve 1mmol of sodium tungstate dihydrate in 20ml of deionized water to obtain a clear and transparent B solution. Add solution A to solution B dropwise, adjust the pH of the mixed solution to 1 with 0.4 mol / L dilute nitric acid, and stir at room temperature for 60 minutes to obtain a white suspension. Take 1ml of Yb 3 + -Er 3+ The solution was added dropwise to 30 mL of white suspension, and the stirring was continued at room temperature. The reaction system was transferred to a polytetrafluoroethylene stainless steel reaction kettle, solvothermally reacted at 160°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com