Microorganism denitrification treatment device

A treatment device and microbial technology, applied in the direction of biological treatment devices, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of destroying the balance of denitrification conversion reaction, low denitrification efficiency, small specific surface area, etc., and achieve improvement Adhering species and biomass, improving denitrification efficiency, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

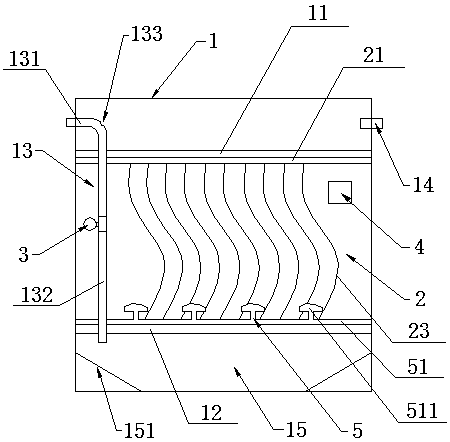

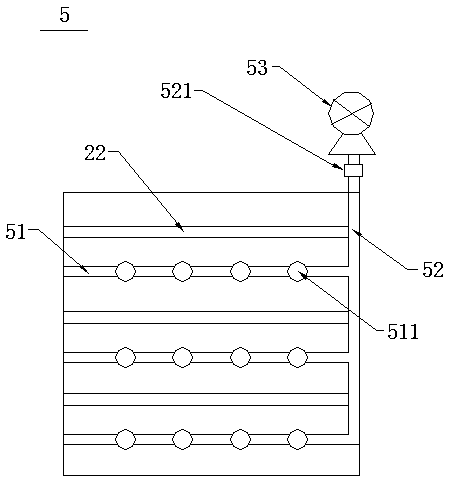

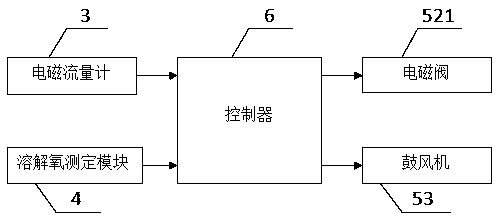

[0023] Example 1: please refer to figure 1 and image 3 , figure 1 It is an overall schematic diagram of a microbial denitrification treatment device according to an embodiment of the present invention, image 3 It is a system schematic diagram of an embodiment of the present invention. The present invention proposes a microbial denitrification treatment device, including a box body 1, a plurality of microbial carriers 2, an electromagnetic flowmeter 3, a dissolved oxygen measurement module 4, an aeration device 5 and a controller 6, and the box body 1 has a plurality of upper A frame 11 , a plurality of lower frames 12 , a water guide pipe 13 and a water outlet 14 .

[0024] A plurality of upper frames 11 located on the same horizontal plane are arranged horizontally and close to the upper port of the box body 1, and the two ends of the upper frames 11 are respectively fixedly connected to the left and right sides of the box body 1, and the plurality of lower frames 12 loc...

Embodiment 2

[0030] Embodiment 2: On the basis of Embodiment 1, the box body 1 also has a mud collection area 15, the mud collection area 15 is located at the lower end of a plurality of lower frames 12, and the mud collection area 15 has two inclined plates 151 arranged symmetrically. The outer sides of one swash plate 151 are fixedly connected with the left and right sides of the box body 1 respectively, and the inner sides of the two slant plates 151 are fixedly connected with the bottom surface of the box body 1 respectively. Sewage treated by the microbial carrier 2 will leave sludge, and the sludge will settle into the sludge collecting area 15, where the two sloping plates 151 can collect the sludge, making it easier to clean. A mud discharge device and a backwashing device can be set in the mud collection area 15, which can be used for forward suction and discharge of mud through the mud discharge device, and can also be reversely flushed in the mud collection area 15 through the ba...

Embodiment 3

[0032] Embodiment 3: On the basis of Embodiment 1 or Embodiment 2, the water guide pipe 13 has a perforation 133, and the perforation 133 is located at the junction of the horizontal pipe 131 and the vertical pipe 132, and the sewage enters the box body 1 from the regulating tank. The height of the liquid level is lower than that of the tank 1. If the amount of sewage entering the tank 1 is small, the sewage may flow back into the regulating tank, and the perforation 133 can destroy the siphon, effectively avoid the siphon phenomenon, and prevent Sewage backflow.

[0033] Preferably, the ratio of the total volume of the porous wire 23 to the total volume of the box 1 is 50%-60%, that is, the filling rate of the porous wire 23 is 50%-60%, and this range includes 50% and 60%. The porous wire 23 with this filling rate has lower running cost and better treatment effect.

[0034] Please refer to Figure 4 , Figure 4 It is a schematic diagram of three microbial denitrification t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com