A process of wrapping the surface layer of solid wood lines with modified pvc

A modified and solid wood technology, which is applied in the direction of wood processing appliances, wooden veneer joints, manufacturing tools, etc., can solve the problems of inability to effectively prevent air from entering wood fibers, uneven density of wood, poor bonding effect, etc. problem, to achieve the effect of eliminating autocatalytic degradation, less prone to dark spots, and the best effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

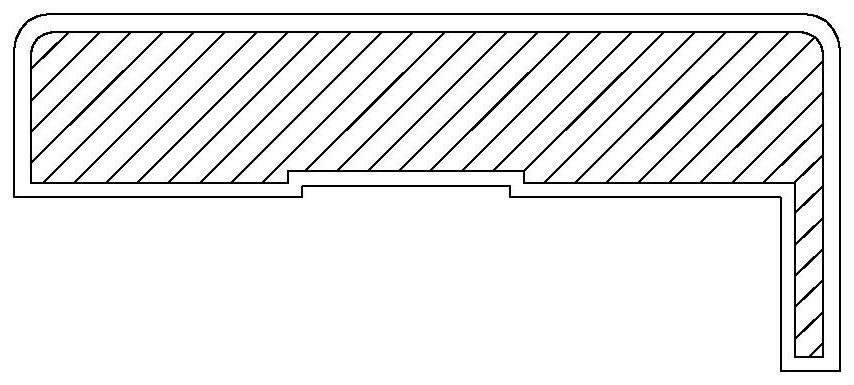

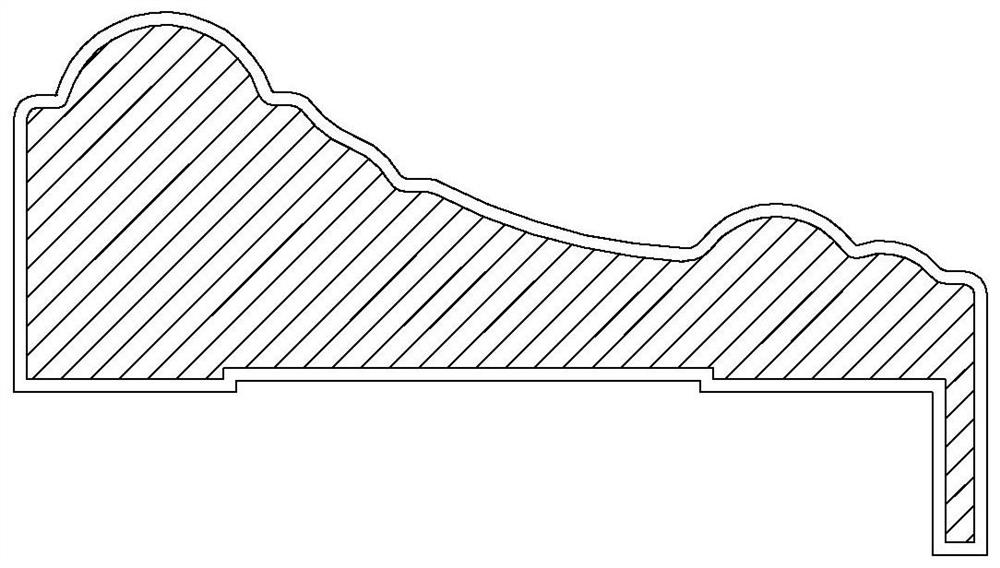

Image

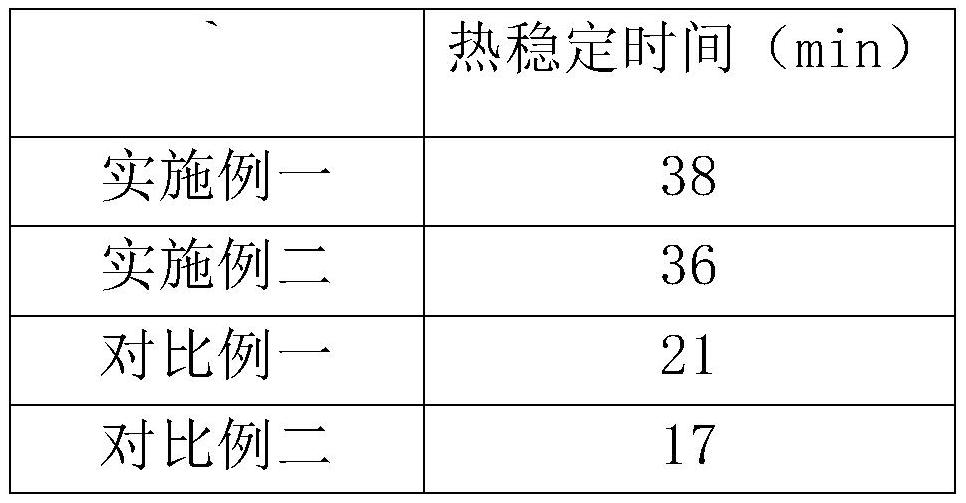

Examples

Embodiment 1

[0041] A modified PVC composite material, comprising the following material composition in parts by weight:

[0042] 40 parts of polyvinyl chloride;

[0043] 10 parts of calcium carbonate;

[0044] 20 parts of wood flour;

[0045] 1 part foaming agent;

[0046] 0.8 parts of paraffin wax;

[0047] 1.5 parts of composite stabilizer;

[0048] 2-3 parts of titanium dioxide;

[0049] Described composite stabilizer comprises following material composition by weight parts:

[0050] 6 parts of zinc stearate;

[0051] 8 parts of calcium stearate;

[0052] 20 parts of plasticizer;

[0053] Antioxidant 689 1 part;

[0054] 5 parts of 1,2-cyclohexanediol diglycidyl ether;

[0055] 2 parts of polypropylene glycol dioxirane methyl ether;

[0056] 5 parts of diethylene glycol dibutyl ether.

[0057] The preparation steps of the modified PVC composite material are as follows:

[0058] (1) Get wood powder and calcium carbonate to dry, and described calcium carbonate is the mixture...

Embodiment 2

[0063] A modified PVC composite material, comprising the following material composition in parts by weight:

[0064] 60 parts of polyvinyl chloride;

[0065] 20 parts of calcium carbonate;

[0066] 40 parts of wood flour;

[0067] 5 parts foaming agent;

[0068] 2 parts paraffin;

[0069] Composite stabilizer 4 parts;

[0070] 2-3 parts of titanium dioxide;

[0071] Described composite stabilizer comprises following material composition by weight parts:

[0072] 10 parts of zinc stearate;

[0073] 30 parts of calcium stearate;

[0074] 35 parts of plasticizer;

[0075] Antioxidant 289 3 parts;

[0076] 10 parts of 1,2-cyclohexanediol diglycidyl ether;

[0077] 5 parts of polypropylene glycol dioxirane methyl ether;

[0078] 10 parts of diethylene glycol dibutyl ether.

[0079] The modified PVC composite material comprises the following preparation steps:

[0080] (1) Get wood powder and calcium carbonate to dry, and described calcium carbonate is the mixture of nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com