Quantum dot light-emitting diode and preparation method thereof

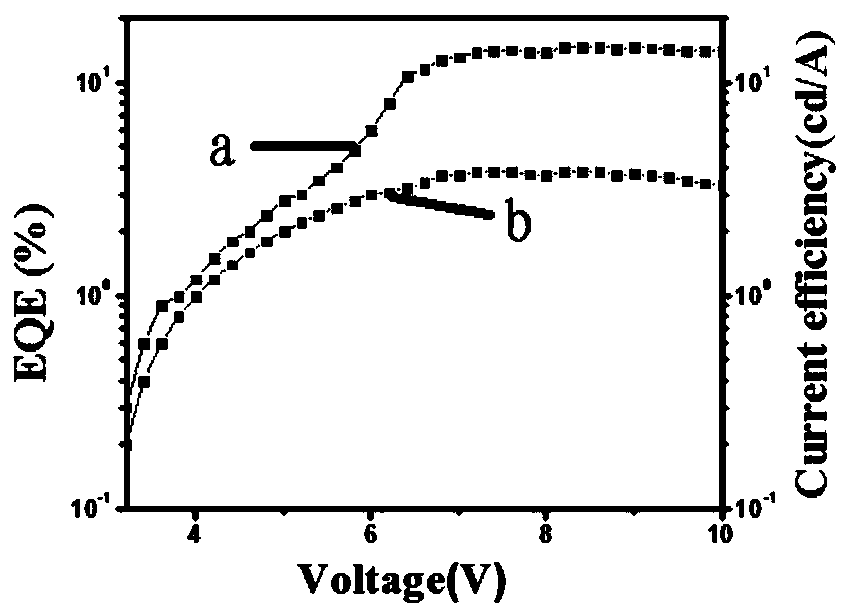

A quantum dot light-emitting and diode technology, applied in the field of diodes, can solve the problems of electrons not participating in radiation recombination, low device efficiency, charge imbalance, etc., and achieve the effects of improving electroluminescence efficiency, improving matching, and preventing leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention provides a method for preparing a quantum dot light-emitting diode described in the above technical solution, comprising the following steps: sequentially preparing a hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer and a cathode on the surface of the anode.

[0034] In the present invention, before the hole injection layer, the hole transport layer, the quantum dot luminescent layer, the electron transport layer and the cathode are sequentially prepared on the surface of the anode, the surface of the anode is preferably cleaned first. In the present invention, when the anode is ITO conductive glass, it is preferable to use deionized water plus detergent, deionized water, acetone and isopropanol to ultrasonically clean the ITO conductive glass for 15 minutes each, and then soak them in alcohol 30min, wipe it clean with lens cleaning paper, and finally put it in a UV ozone machine for 20min...

Embodiment 1

[0054] Preparation of NiO solution: 1mmol of Ni(NO 3 ) 2 ·6H 2 O was dissolved in 10 mL of 2-methoxyethanol, stirred at 50°C for 1 h, then 10 μL of acetylacetone was added, stirred at room temperature for 1 h, and aged for 24 h to obtain a NiO solution.

[0055] Cleaning of ITO conductive glass: In an ultrasonic wave, clean the ITO conductive glass with deionized water plus detergent, deionized water, acetone and isopropanol for 15 minutes each, then soak it in alcohol for 30 minutes, and clean it with lens cleaning paper Wipe it clean, and finally place it in an ultraviolet ozone machine to irradiate for 20 minutes. The wavelength of ultraviolet light in the ultraviolet ozone machine is 325nm, and the irradiation time is 60s.

[0056] Spin-coat NiO hole injection layer: fix the ITO conductive glass on the homogenizer, adjust the speed of the homogenizer to 4000rpm, set the time to 45s, spin-coat a 15nm NiO hole injection layer, and bake it at 150°C 30min, and irradiated in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com