Soybean glue with high friction coefficient, preparation method of soybean glue and application of soybean glue in plate making

A high friction coefficient, soybean gum technology, applied in the preparation of animal glue or gelatin, chemical instruments and methods, adhesives, etc., can solve the problems of reducing the proportion of modified additives, difficult production lines, and high costs, and achieve the best water resistance. performance and weather resistance, solve the difficulty of gluing, and improve the effect of gluing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

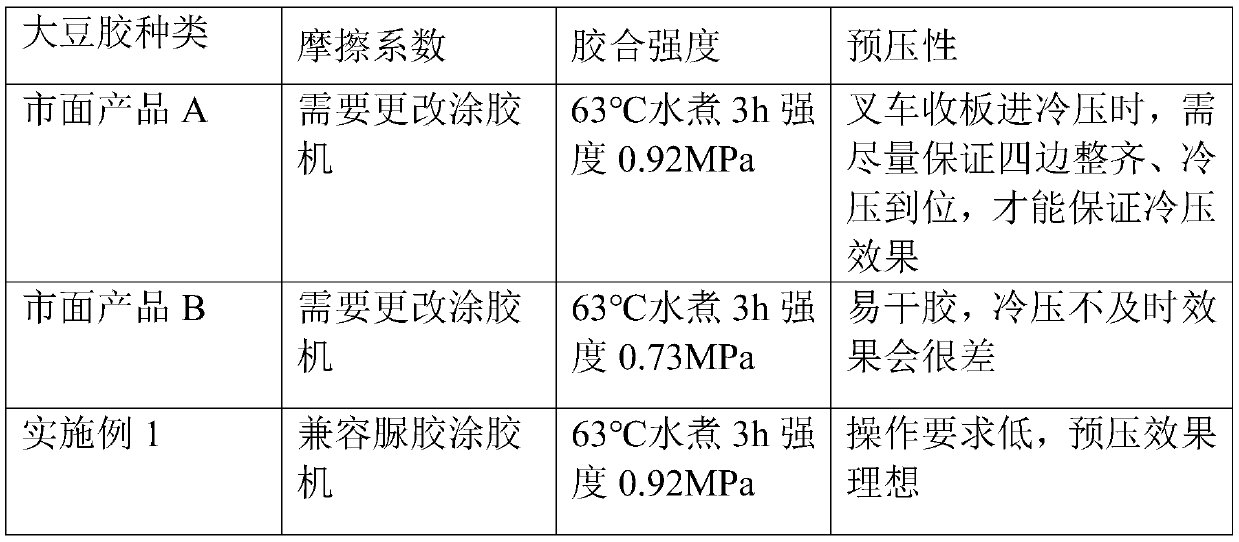

Examples

Embodiment 1

[0035] A kind of preparation method of soybean gum with high coefficient of friction in this embodiment comprises the following steps:

[0036] (1) Add 2.5g of sodium hydroxide and 100g of water into a three-neck round bottom flask, stir for 5 minutes to dissolve the sodium hydroxide, then add 0.5g of sodium silicate, 0.5g of sodium sulfite and 0.2g of urea to the lye, and stir 3min, the temperature is 80-96°C, and the preliminary mixed solution is obtained;

[0037] (2) Add 10 g of defatted soybean powder and 5 g of mica powder to the preliminary mixed solution, stir for 10 minutes, and the temperature is 80 ° C, so that the defatted soybean powder and mica powder are fully dispersed to obtain a mixed solution;

[0038] (3) 0.3g polyamide polyamine-epichlorohydrin (PAE) is prepared into an aqueous solution with a mass concentration of 12.5%, and the polyamide polyamine-epichlorohydrin aqueous solution is added to the mixed solution, and stirred for 10min to obtain solidified...

Embodiment 2

[0042] Adopt the soybean glue board that embodiment 1 prepares, comprise the following steps:

[0043] (I) Take 100 parts by weight of soybean gum prepared in Example 1, add 4 parts by weight of silicone-modified acrylic resin emulsion (glass transition temperature is -15°C to -5°C), stir for 5 minutes, and then add 0.1 part by weight of cypermethrin to prevent insects agent and 0.1 parts by weight of polyvinyl alcohol, stirred for 3 minutes to obtain the finished product modified soybean gum;

[0044] (II) Coating the modified soybean gum on the surface of the poplar veneer, stabilizing the soybean gum through the first cold pressing and the first hot pressing, and obtaining a slab;

[0045] The cold pressing pressure of the first cold pressing is 0.8MPa, and the cold pressing time is 30min; the hot pressing pressure of the first hot pressing is 0.6MPa, the hot pressing temperature is 100°C, and the hot pressing rate is 0.6min / mm;

[0046] (Ⅲ) Sand the slab, and coat the fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com