Zinc alloy vascular stent material having ultra-high-flexible coating layer with drug sustained-release function

A flexible coating, vascular stent technology, applied in the direction of coating, metal material coating technology, medical science, etc., can solve the problems of insufficient flexibility, hard coating cracking, failure and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Provide a Zn-(2~4 at%) Li alloy as a matrix.

[0030] (2) After the surface of the substrate is polished, cleaned and dried, it is placed in a PECVD equipment, and 5% O is mixed in Ar 2 Form Ar / O 2 The plasma surface activation pretreatment was carried out in the atmosphere, and the parameters were set as follows: voltage 10W, chamber pressure 0.5mbar, total gas flow 10sccm, and treatment time 60s.

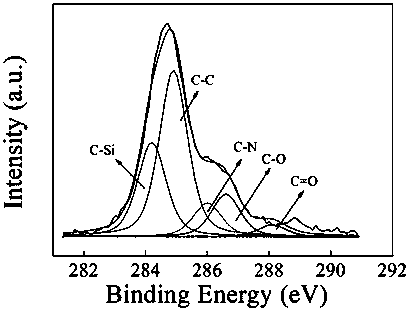

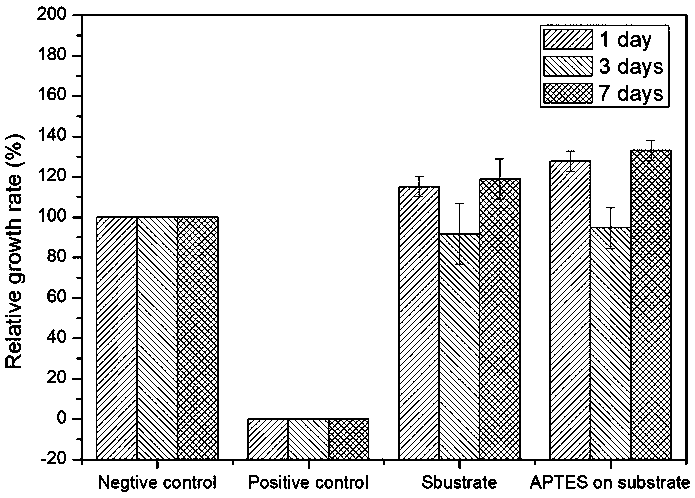

[0031] (3) After the surface activation pretreatment of the base material is completed, 3-aminopropyltriethoxysilane (APTES) is sprayed into the reaction chamber to atomize the monomer, and it is polymerized and deposited in Ar plasma with high-density amino functional groups APTES coating, where the parameters are set as: voltage 20W, chamber pressure 1.0mbar, total air flow 20sccm, processing time 30s; such as figure 1 The XPS C1s high-resolution spectrum of the APTES coating with a high density of amino functional groups deposited on the surface of the zinc alloy b...

Embodiment 2

[0036] (1) Provide a Zn-(2~4 at%) Li alloy as a matrix.

[0037] (2) After polishing, cleaning, and drying the surface of the substrate, place it in PECVD equipment, mix 5% O2 in Ar to form Ar / O2 atmosphere, and perform plasma surface activation pretreatment. The parameters are set as: voltage 10W, chamber pressure 0.5 mbar, the total air flow is 10sccm, and the processing time is 60s.

[0038] (3) After the surface activation pretreatment of the base material is completed, (3-aminopropyl)triethoxysilane (APTES) is sprayed into the reaction chamber to atomize the monomer, and the polymerization deposition in Ar plasma has a high density APTES coating with amino functional groups, where the parameters are set as: voltage 20W, chamber pressure 1.0mbar, total gas flow 20sccm, treatment time 30s.

[0039] (4) Dissolve PLGA in dichloromethane to prepare the PLGA solution required for this experiment. The concentration of PLGA in dichloromethane is 10 mg / mL. Then fully mix 0.1%wt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com