High-performance environmentally-friendly composite film for water treatment

An environmentally friendly water, high-performance technology, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of improving mechanical properties and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

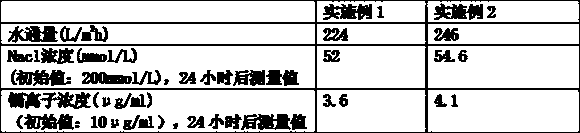

Examples

Embodiment 1

[0033] A high-performance and environmentally friendly composite membrane for water treatment is composed of a four-layer structure, including a bottom layer, a connection layer, a treatment layer and a surface layer in sequence. The bottom layer is a polymer porous support material, the connecting layer is a porous triacetate cellulose coating layer, the treatment layer is a cross-linked biomass hybrid membrane, and the surface layer is a porous biomass membrane.

[0034] The polymer porous support material is a polyamide-based polymer porous material.

[0035] The ratio of the pore area of the cross-section of the polymer porous support material to the membrane area is 35%, and the pore diameter is between 50-500 microns.

[0036] The connection layer is a porous triacetate cellulose membrane layer, the thickness of which is 120 microns, and the pore size is between 2-10 microns.

[0037] The preparation of the cross-linked biomass hybrid film is to use chitosan as the ma...

Embodiment 2

[0056] A high-performance and environmentally friendly composite membrane for water treatment is composed of a four-layer structure, including a bottom layer, a connection layer, a treatment layer and a surface layer in sequence. The bottom layer is a polymer porous support material, the connecting layer is a porous triacetate cellulose coating layer, the treatment layer is a cross-linked biomass hybrid membrane, and the surface layer is a porous biomass membrane.

[0057] The polymer porous support material is a polysulfone polymer porous material.

[0058] The ratio of the pore area of the cross-section of the polymer porous support material to the membrane area is 32%, and the pore diameter is between 50-300 microns.

[0059] The connecting layer is a porous triacetate cellulose film layer, the thickness of which is 135 microns, and the pore size is between 3-10 microns.

[0060] The preparation of the cross-linked biomass hybrid film is to use chitosan as the main raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com