A kind of hybrid film modified carbon fiber composite material and preparation method thereof

A composite material and carbon fiber technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as poor toughness and electrical conductivity, increase interlayer fracture toughness, reduce the impact of resin viscosity, The effect of lowering the percolation threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

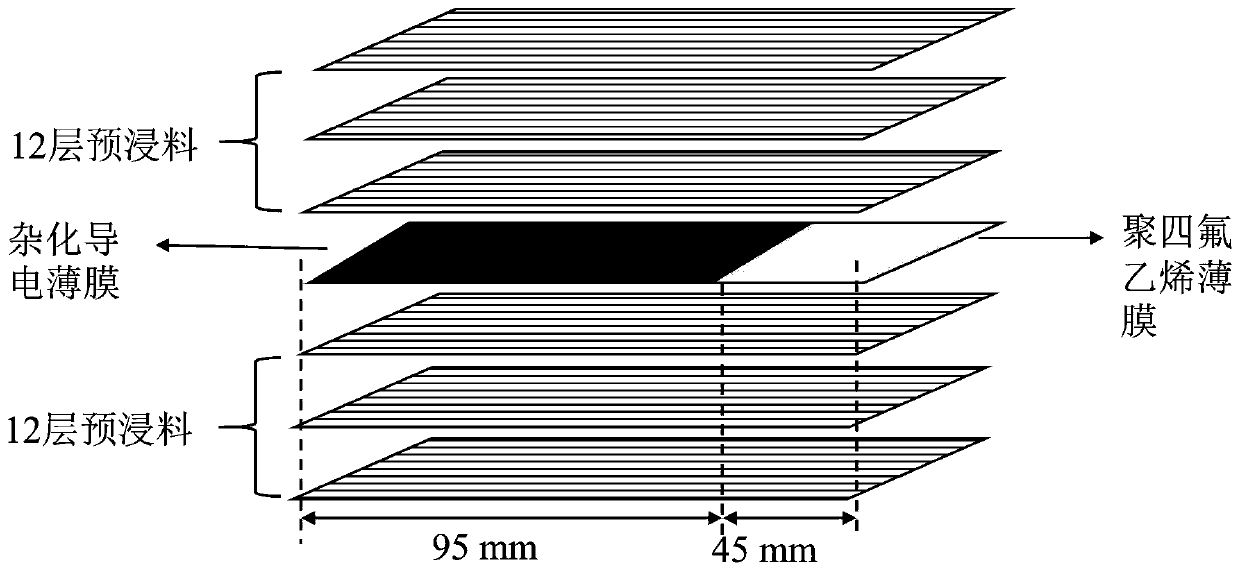

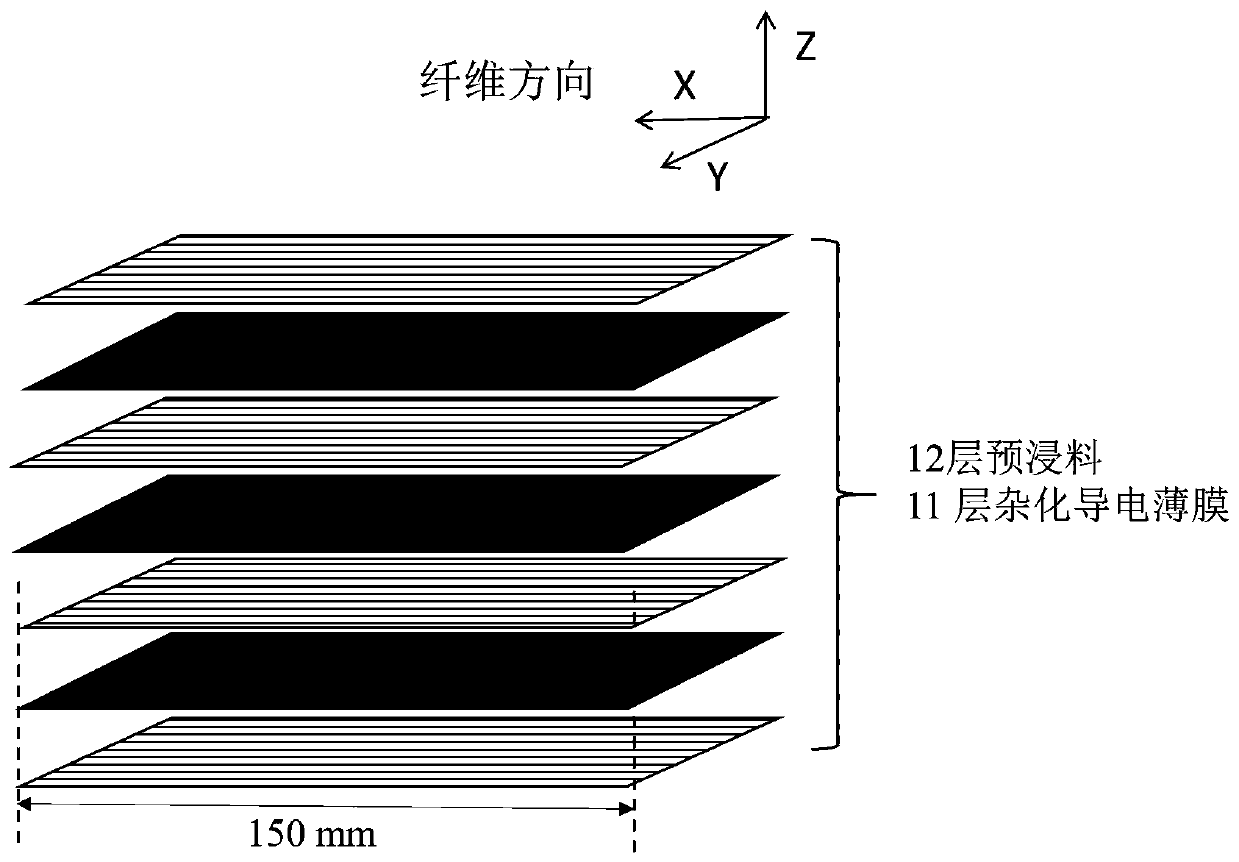

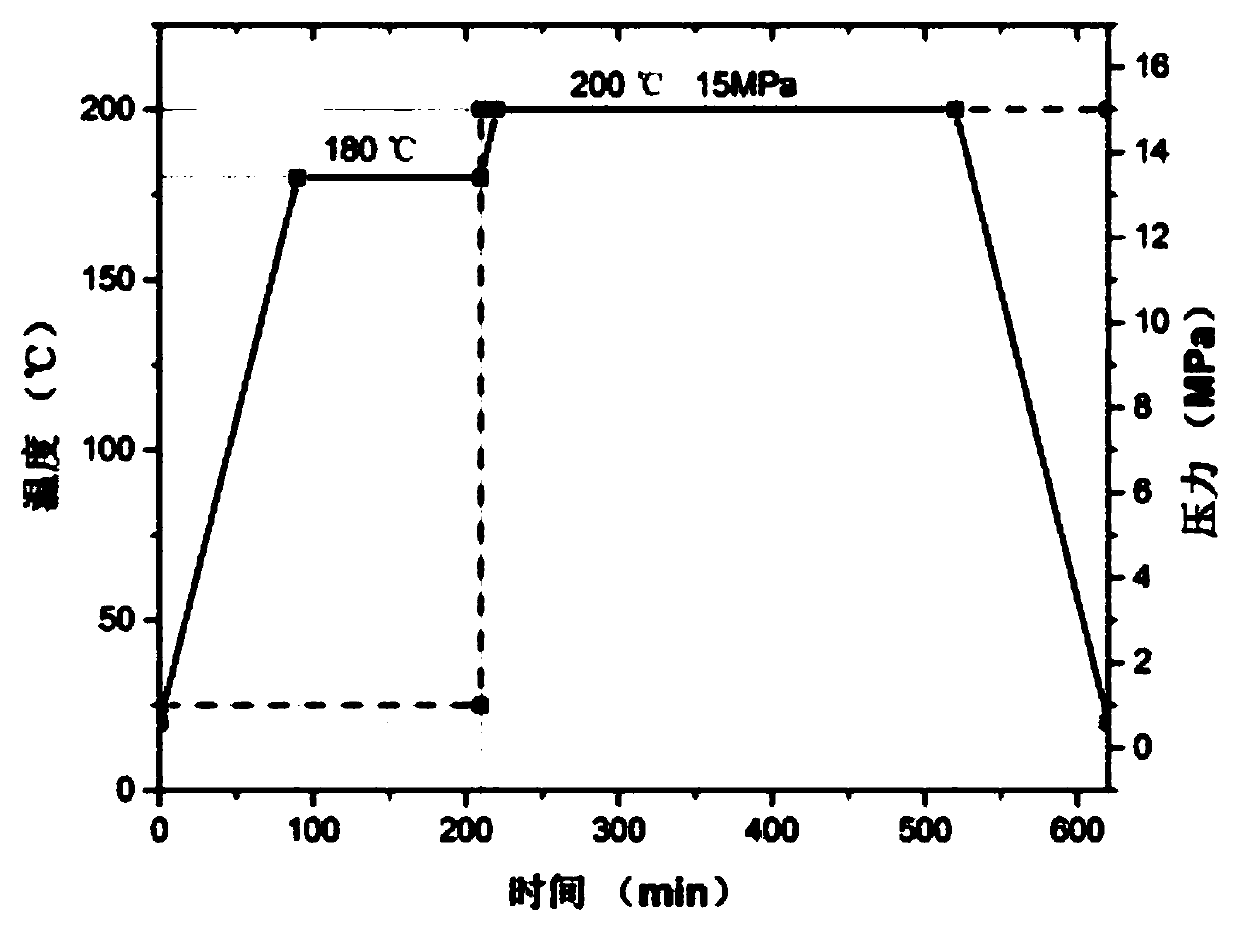

[0024] A method for preparing a hybrid film-modified carbon fiber composite material, the steps are as follows:

[0025] S1. Preparation of CNT / AgNP composite filler: the composite weight ratio of CNT and AgNP is 10:1, the dosage of silver nitrate is 0.12mM (mmol), the dosage of carbon nanotube is 1mg, the dosage of sodium citrate aqueous solution is 10mL, sodium citrate The mass fraction of the aqueous solution is 1 wt%. The average diameter of carbon nanotubes used is 9.5nm, the average length is 1.5μm, and the specific surface area is 250-300m 2 / g. Specific operation: Put the silver nitrate aqueous solution, carbon nanotubes and sodium citrate aqueous solution in the flask in turn, place the flask in an oil bath and heat it in an oil bath, stir and react for 1 hour at 120°C until the solution turns gray, and centrifuge (centrifuge) Rotating speed 10000rpm), the sediment obtained is the CNT / AgNP composite filler; the composite filler is stored in absolute ethanol for subs...

Embodiment 2

[0032] A method for preparing a hybrid film-modified carbon fiber composite material, the steps are as follows:

[0033] S1. Preparation of CNT / AgNP composite filler: the composite weight ratio of CNT and AgNP is 5:1, the dosage of silver nitrate is 0.22mM (mmol), the dosage of carbon nanotube is 1mg, the dosage of sodium citrate aqueous solution is 10mL, sodium citrate The mass fraction of the aqueous solution is 1 wt%. The average diameter of carbon nanotubes used is 9.5nm, the average length is 1.5μm, and the specific surface area is 250-300m 2 / g. Specific operation: Put the silver nitrate aqueous solution, carbon nanotubes and sodium citrate aqueous solution in the flask in turn, place the flask in an oil bath and heat it in an oil bath, stir and react for 2 hours at 110°C until the solution turns gray, and centrifuge (centrifuge) Rotating speed 10000rpm), the sediment obtained is the CNT / AgNP composite filler; the composite filler is stored in absolute ethanol for subs...

Embodiment 3

[0038] A method for preparing a hybrid film-modified carbon fiber composite material, the steps are as follows:

[0039] S1. Preparation of CNT / AgNP composite filler: the composite weight ratio of CNT and AgNP is 2:1, the dosage of silver nitrate is 0.53mM (mmol), the dosage of carbon nanotube is 1mg, the dosage of sodium citrate aqueous solution is 10mL, sodium citrate The mass fraction of the aqueous solution is 1 wt%. The average diameter of carbon nanotubes used is 9.5nm, the average length is 1.5μm, and the specific surface area is 250-300m 2 / g. Specific operation: Put the silver nitrate aqueous solution, carbon nanotubes and sodium citrate aqueous solution in the flask in turn, place the flask in an oil bath and heat it in an oil bath, stir and react for 2 hours at 110°C until the solution turns gray, and centrifuge (centrifuge) Rotating speed 10000rpm), the sediment obtained is the CNT / AgNP composite filler; the composite filler is stored in absolute ethanol for subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com