A Tunable Waveguide Grating Surface Emitter

A technology of waveguide grating and grating surface, which is applied to optical waveguides, instruments, optics, etc., can solve the problems of reducing the heating efficiency of thermo-optic devices, low thermal conductivity of isolation layers, and limiting the speed of thermo-optic regulation, and achieves convenient design and thermal conductivity. The effect of high coefficient and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

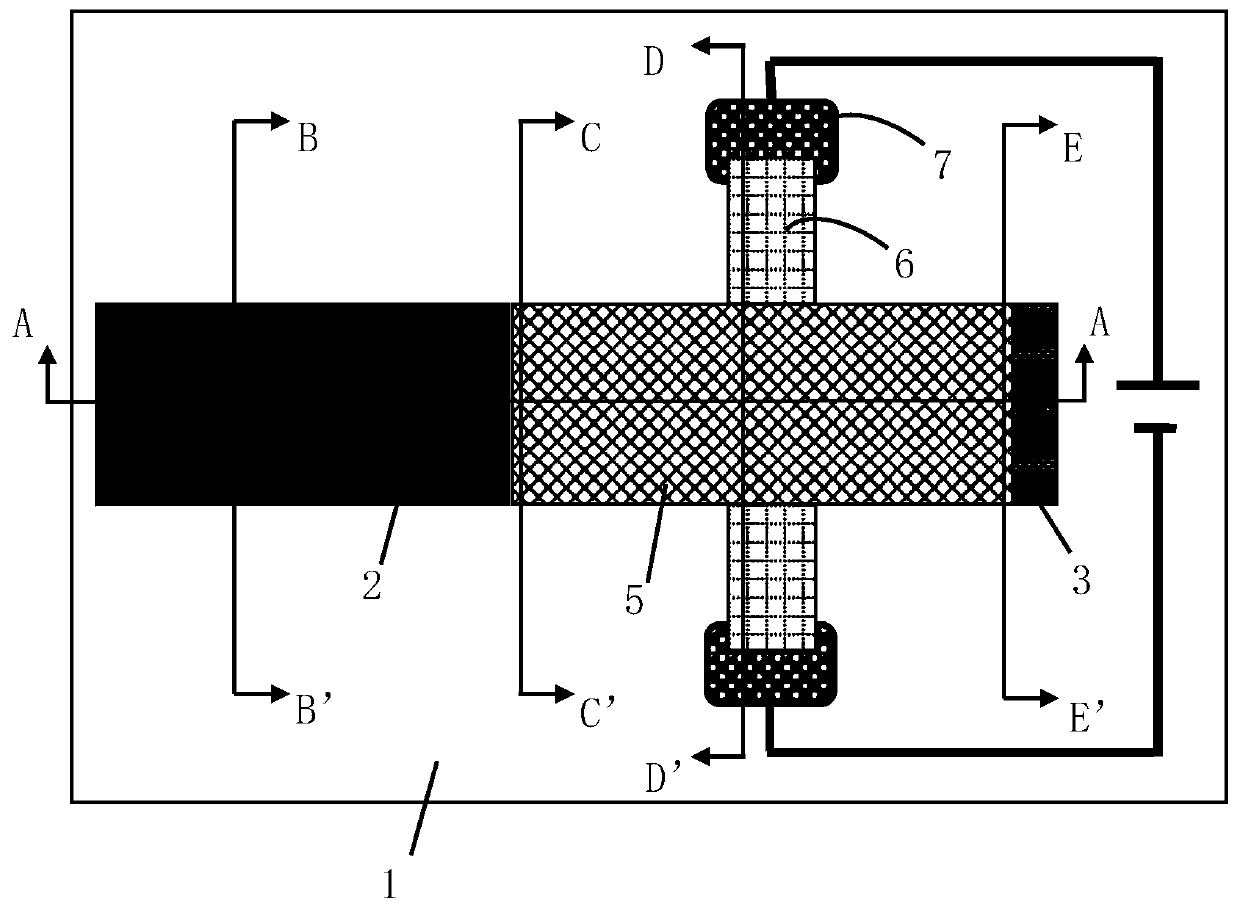

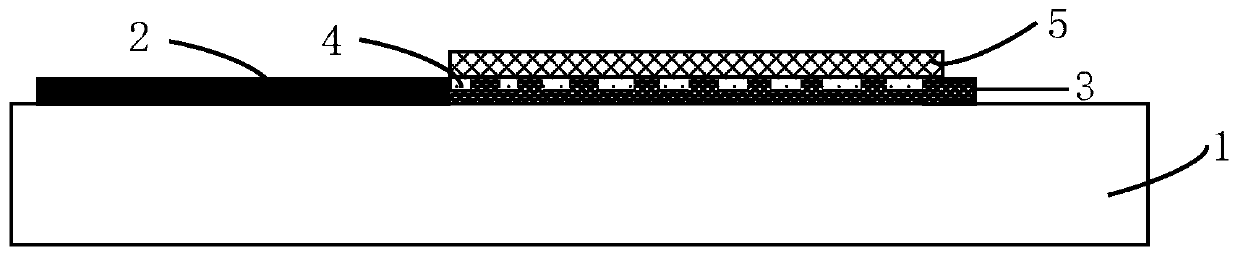

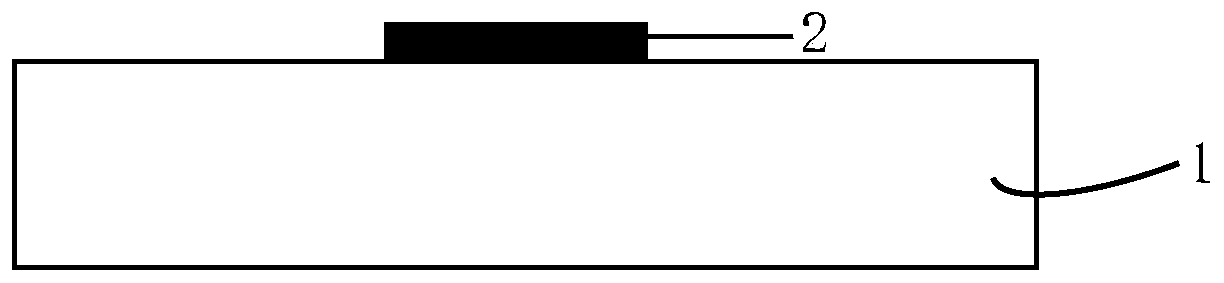

[0050] Only a single core strip optical waveguide and a micro-graphene heater are arranged, such as figure 1 shown.

[0051] The silicon nanowire optical waveguide based on silicon insulator (SOI) material is selected: the core layer is silicon material, the thickness is 220nm, and the refractive index is 3.4744; the lower cladding material is silicon dioxide, the thickness is 2μm, and the refractive index is 1.4404; The upper cladding material is air, and the refractive index is approximately 1. Considering that the incident center wavelength is 1550nm, the TE polarization mode is adopted.

[0052] The core layer is etched into a strip waveguide with a certain width by photolithography and other processes, and the coupling grating is etched at the front end to couple the light in the fiber into the silicon waveguide. The end is also etched into a grating structure, but the size of the coupling grating is different. different. The etching depth is 0.065 μm, the period is 0....

Embodiment 2

[0057] Such as Figure 8 and Figure 9 As shown, the specific implementation includes multiple core layer strip optical waveguides and only one micro-graphene heater, multiple core layer strip optical waveguides are arranged in parallel on the lower cladding layer, and the micro-graphene heaters are laid on the common multiple cores On the grating diffraction area of the strip optical waveguide, multiple grating diffraction areas are cascaded. Here, in order to make the graphene pavement smoother, after the input waveguide and waveguide grating are etched, HSQ photoresist is used to fill the grating etching area and the interval area between adjacent waveguides. Due to the increase of the graphene area, higher power is required to increase the waveguide to the same temperature, and the heating efficiency is lower than that of Example 1. The same mode light is input into each waveguide, but the adjacent waveguides maintain a fixed phase difference (the phase difference can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com