Nano fiber membrane of dual-loading nucleus/shell structure and preparation method of nano fiber membrane

A nanofiber membrane, dual-loading technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of low effective dose and low absorption rate, and achieve increased persistence, low cytotoxicity, and excellent biological phase. Capacitive and Biodegradable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preferred embodiment of the present invention provides a dual-loaded core / shell structured nanofiber membrane. The specific preparation method is as follows:

[0043] Weigh chitosan (CS) and polyoxyethylene (PEO) with a mass ratio of 8:2, where PEO is used as a fiber-forming aid, and weigh the nano-hydroxyapatite with a mass of 1 / 9 of the total mass of CS and PEO Stone (nHA), stir with trifluoroacetic acid as a solvent until it is completely dissolved, configure it into a shell spinning solution with a solute weight to solvent volume ratio of 4g:100mL; then weigh a polycaprolactone with a mass ratio of 9:1 ( PCL) and simvastatin, stirred with trifluoroethanol as a solvent until completely dissolved, and configured into a nuclear layer spinning solution with a solute weight to solvent volume ratio of 13g:100mL;

[0044] Inject the shell spinning solution into the outer 5mL syringe, and the core spinning solution into the inner 5mL syringe. Use a coaxial spinning nozzle (t...

Embodiment 2

[0046] The preferred embodiment of the present invention provides a dual-loaded core / shell structured nanofiber membrane. The specific preparation method is as follows:

[0047] Weigh chitosan (CS) and polyoxyethylene (PEO) with a mass ratio of 8:2, where PEO is used as a fiber-forming aid, and weigh the nano-hydroxyapatite with a mass of 1 / 9 of the total mass of CS and PEO Stone (nHA), stir with trifluoroacetic acid as a solvent until it is completely dissolved, configure it into a shell spinning solution with a solute weight to solvent volume ratio of 4g:100mL; then weigh a polycaprolactone with a mass ratio of 9:1 ( PCL) and simvastatin, mixed with dichloromethane as a solvent until completely dissolved, and configured into a nuclear layer spinning solution with a solute weight to solvent volume ratio of 13g:100mL;

[0048] Inject the shell spinning solution into the outer 5mL syringe, and the core spinning solution into the inner 5mL syringe. Use a coaxial spinning nozzle (the ...

Embodiment 3

[0050] The preferred embodiment of the present invention provides a dual-loaded core / shell structured nanofiber membrane. The specific preparation method is as follows:

[0051] Weigh chitosan (CS) and polyoxyethylene (PEO) with a mass ratio of 7:3, where PEO is used as a fiber-forming aid, and weigh the nano-hydroxyapatite with a mass of 1 / 9 of the total mass of CS and PEO Stone (nHA), stir with trifluoroacetic acid as a solvent until it is completely dissolved, configure it into a shell spinning solution with a solute weight to solvent volume ratio of 4g:100mL; then weigh a polycaprolactone with a mass ratio of 9:1 ( PCL) and simvastatin, stirred with trifluoroethanol as a solvent until completely dissolved, and configured into a nuclear layer spinning solution with a solute weight to solvent volume ratio of 13g:100mL;

[0052] Inject the shell spinning solution into the outer 5mL syringe, and the core spinning solution into the inner 5mL syringe. Use a coaxial spinning nozzle (t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

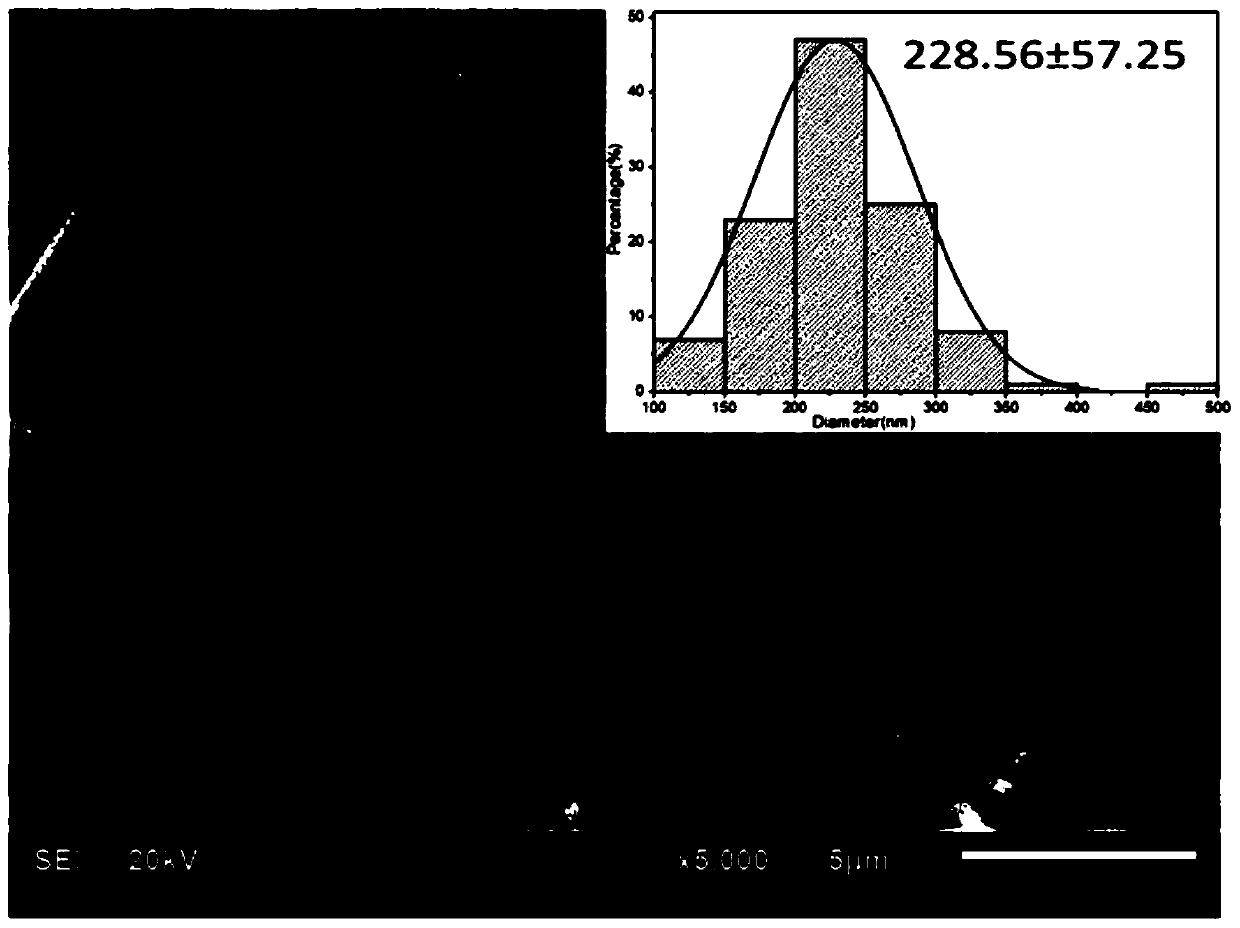

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com