Water-blocking front plate integrated with solar cell interconnection and processing method thereof

A processing method and front panel technology, applied in the direction of sustainable manufacturing/processing, circuits, electrical components, etc., can solve problems affecting product quality, prone to breakage, cell displacement, etc., to reduce equipment and operating costs, and ensure structure Stability, the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The preparation method of the insulating reticle is configured to include:

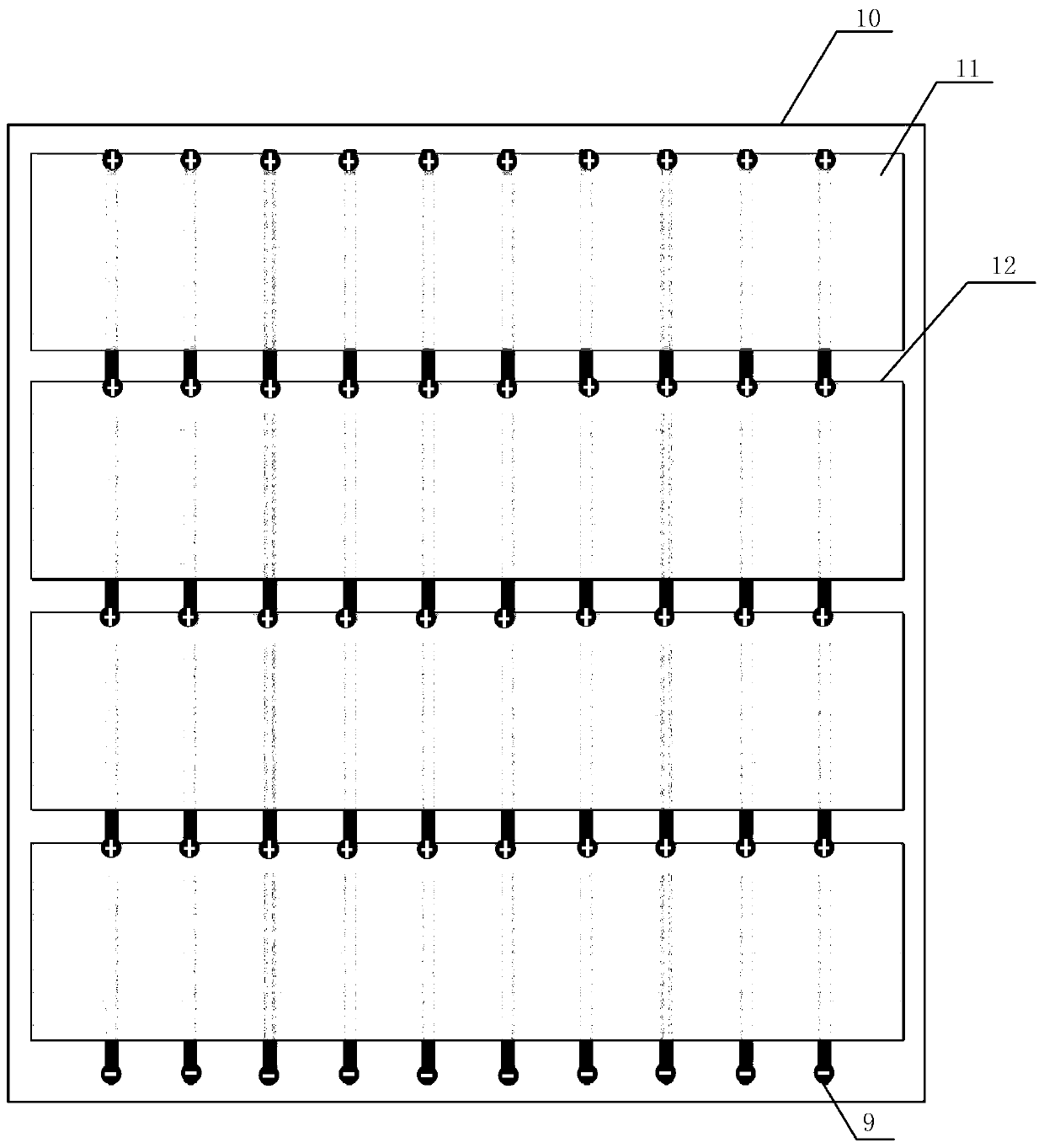

[0078] Carve from the front surface electrode of the battery to the back electrode, but do not cut through the back electrode, so that the welding areas of the sub-battery are spaced apart from other positions of the sub-battery, and are used to make the welding point area of the sub-battery relative to other parts of the sub-battery In other words, it becomes an isolated island, which avoids the short circuit between the bottom electrode and the front electrode of the sub-battery during welding.

[0079] In another example, in step S2, the welding method of the sub-battery and the series connection point on the corresponding series connection circuit is configured to include:

[0080] Laser technology is used to remove the battery film layer at the confluence point on the main grid line bus bar to leak the bottom electrode of the second sub-battery, so that the welding point on the water-blo...

Embodiment

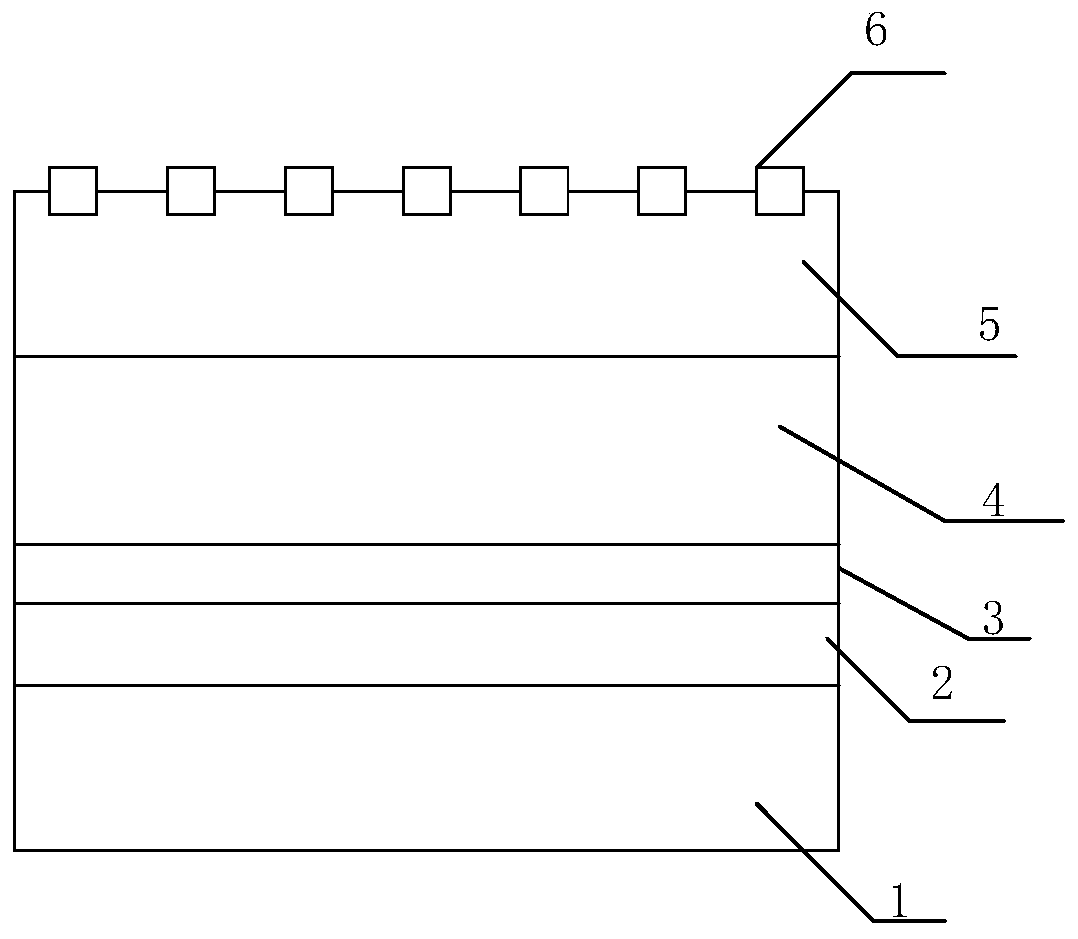

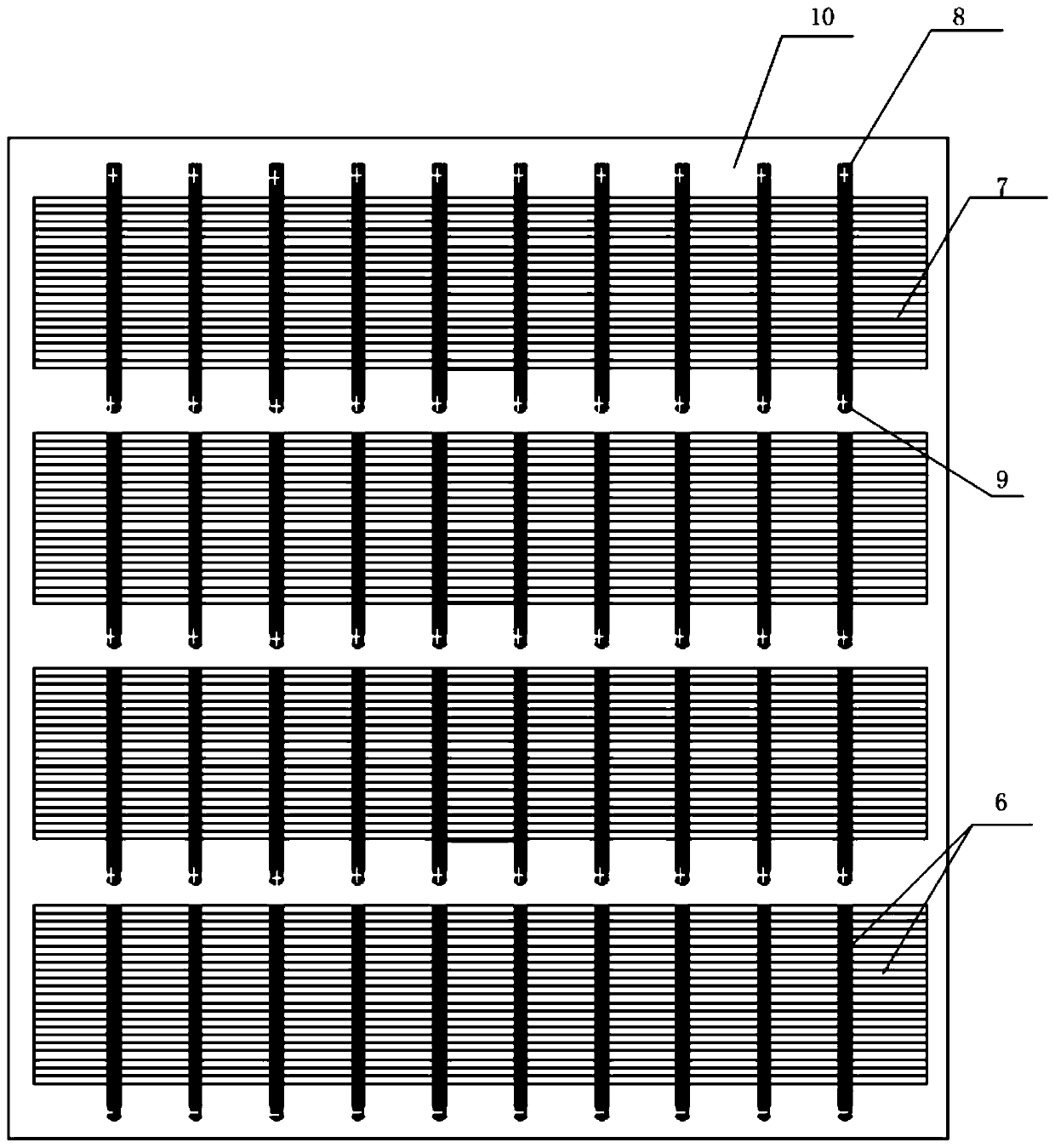

[0083] The invention adopts a flexible or rigid substrate with good weather resistance, corrosion resistance, anti-fouling and mechanical properties, and a water-blocking and anti-reflection optical film such as pressure-sensitive adhesive, silicon dioxide, etc., and high-transmission and high-temperature-resistant plastics such as polyethylene terephthalic acid. The high-performance water-blocking board is used as the base material, and the thermoplastic sealing adhesive material is evenly prepared on the base material by coagulation film, casting and other processes on one side, and then the serial circuit is prepared by screen printing or developing and etching process , forming a packaging front plate with a series connection circuit, a sealing adhesive material, and a weather-resistant and water-resistant functional layer. Place the sub-battery with the light-facing side down and contact the serial circuit of the water-blocking front plate, arrange them at the designated p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com