Nitrogen-doped carbon-coated Co-based MOF derivative material, preparation method thereof and application thereof

A nitrogen-doped carbon and coating technology is applied in the field of nitrogen-doped carbon-coated MOF-derived Co-CoP composite materials and their preparation, which can solve the problem of inability to meet large-scale commercialization needs, limited precious metal reserves, and large catalytic effect. The problem is to improve the catalytic effect of electrolyzed water, broaden the scope of PH use, and achieve the effect of good catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A preparation method of Co-based MOF-derived materials coated with nitrogen-doped carbon

[0066] Preparation of metal organic framework compound ZIF-67

[0067] Take 0.4g of cobalt nitrate and 3g of methylimidazole and dissolve them in 20ml of water in an autoclave. The reaction temperature is 150-200°C, and the reaction time is 2h in a high-box oven. After the reaction is cooled, the purple metal organic framework compound ZIF-67 is obtained;

[0068] preparation of solid mixture

[0069] Dissolve 1g of metal-organic framework compound ZIF-67, 1g of polyvinylpyrrolidone and 1g of melamine in 100ml of water to obtain a mixed solution, freeze-dry the mixed solution to obtain a solid mixture;

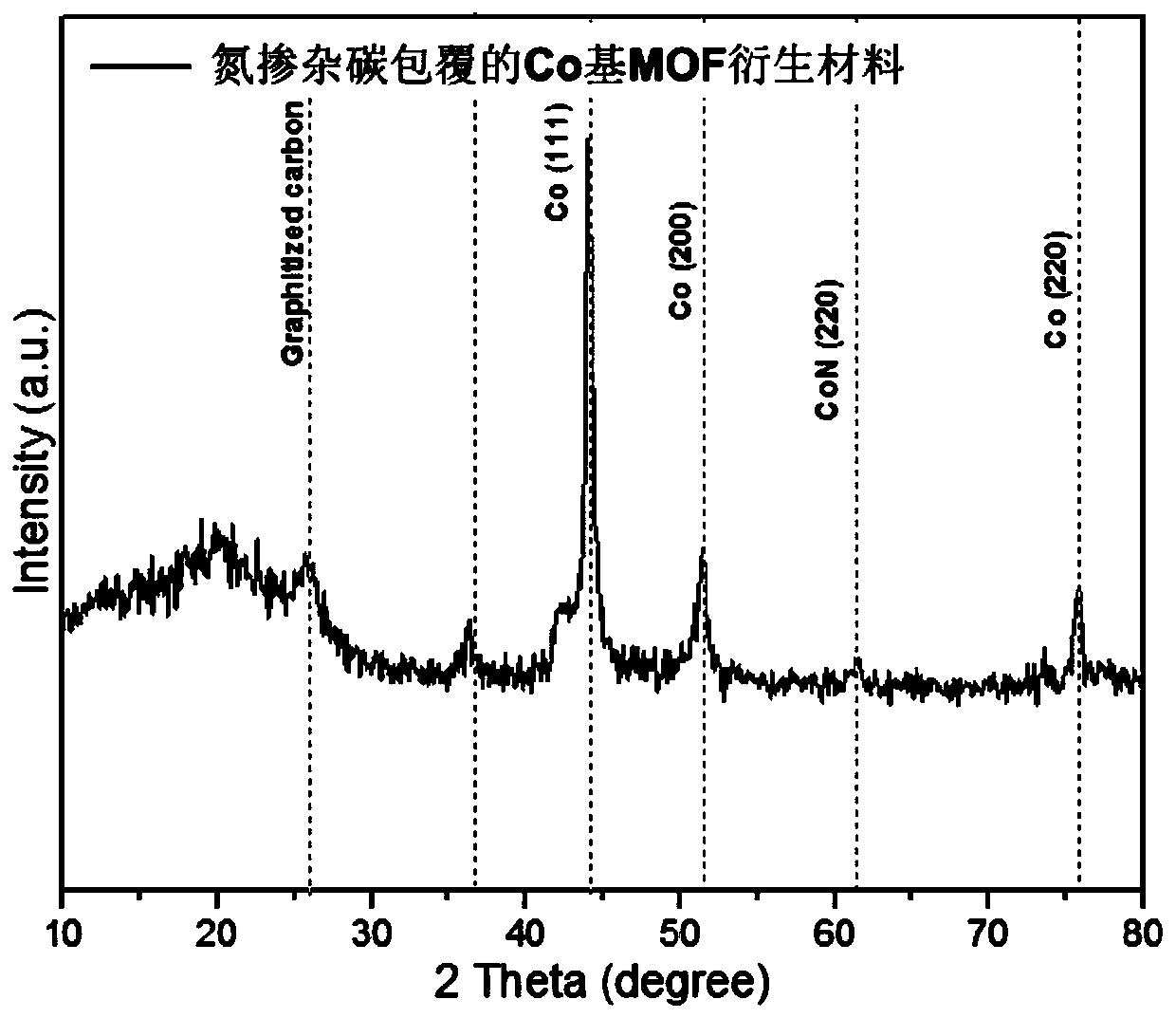

[0070] Preparation of nitrogen-doped carbon-coated Co-based MOF-derived materials

[0071] The solid mixture is placed in a furnace, purged with argon, calcined at a temperature of 600-1000° C. for 2 hours, and cooled to obtain a Co-based MOF derivative material coated with nitr...

Embodiment 2

[0084] The nitrogen-doped carbon-coated Co-based MOF derived material obtained in Example 1 was mixed with a phosphorus source, calcined for 2 hours at 500°C under argon protection, and cooled naturally to obtain a nitrogen-doped carbon-coated MOF-derived Co-CoP composite Material.

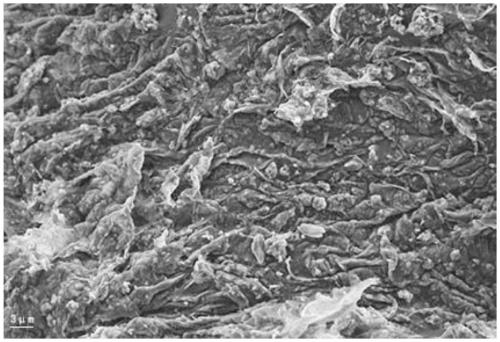

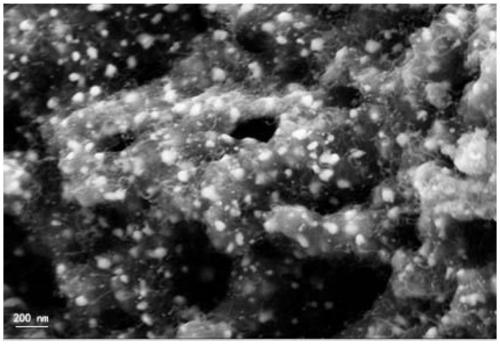

[0085] Experiment description

[0086] A JSM-7500F scanning electron microscope (SEM) was used to observe the morphology of electrolytic water-splitting catalytic materials of nitrogen-doped carbon-coated MOF-derived Co-CoP composites, as shown in Figure 10 shown. It can be seen from the SEM photos that MOF has a good dispersion effect in the carbon matrix. After high-temperature calcination, due to the reaction of the cobalt in the MOF with the carbon-based material, a large number of nanotube structures appear on the surface of the composite material, and the length of the nanotubes is tens to hundreds of nanometers. This special composite structure and good dispersion of nanomaterials revea...

Embodiment 3

[0096] A preparation method of nitrogen-doped carbon-coated MOF-derived Co-CoP composites

[0097] Preparation of metal organic framework compound ZIF-67

[0098] Dissolve cobalt nitrate and methylimidazole in water in an autoclave, the reaction temperature is 150-200°C, the reaction time is 2 hours in a high-box oven, and the purple metal organic framework compound ZIF-67 is obtained after the reaction is cooled;

[0099] preparation of solid mixture

[0100] Dissolving metal-organic framework compound ZIF-67, polyvinylpyrrolidone and melamine in 100ml of water to obtain a mixed solution, and freeze-drying the mixed solution to obtain a solid mixture;

[0101] Preparation of nitrogen-doped carbon-coated Co-based MOF-derived materials

[0102] The solid mixture was placed in a furnace and purged with argon, calcined at a temperature of 600 ° C for 2 h, and cooled to obtain a Co-based MOF derivative material coated with nitrogen-doped carbon

[0103] Preparation of nitrogen-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com