Method and device for preventing electrical desalting tank oil sludge sedimentation by means of ultrasonic waves

A technology of ultrasonic and electric desalination, which is applied to cleaning methods using liquids, chemical instruments and methods, cleaning methods and appliances, etc. It can solve problems such as serious scaling, increased power consumption of electric desalination tanks, and low utilization of ultrasonic waves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] In the method for preventing oil sludge deposition in electric desalination tanks described in Example 1, the crude oil is mixed and then enters the ultrasonic action device, and in the ultrasonic action device, the structure of the ultrasonic action area forms a mixed action mode of parallel ultrasonic waves and pipeline reflection ultrasonic waves The superposition of ultrasonic waves realizes the standing wave field effect, and the ultrasonic wave extends infinitely along the fluid pipeline. Through the formed standing wave field and the no dead angle coverage and infinite extension of ultrasonic propagation, the mixed crude oil is ultrasonically treated, and then enters the electric desalting tank after treatment. Perform electro-desalination.

[0082] The sound intensity of ultrasonic waves in ultrasonic treatment is 0.03-10w / cm 2 , the frequency is 10kHz-200kHz.

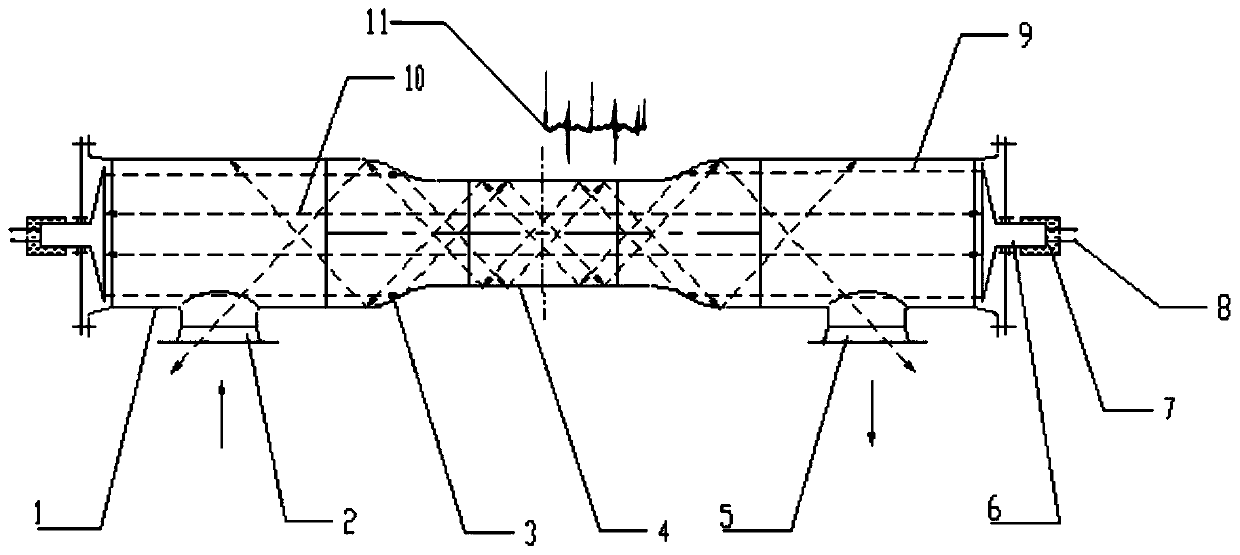

[0083] Ultrasonic action device 12 comprises ultrasonic action area and ultrasonic transducer 6, and...

Embodiment 2

[0111] In the method for preventing oil sludge deposition in electric desalination tanks described in Example 2, crude oil is mixed and then enters the ultrasonic action device, and in the ultrasonic action device, the structure of the ultrasonic action area forms a mixed action mode of parallel ultrasonic waves and pipeline reflected ultrasonic waves The superposition of ultrasonic waves realizes the standing wave field effect. Through the formed standing wave field and the no-dead-angle coverage and infinite extension of ultrasonic propagation, the mixed crude oil is ultrasonically treated. After the treatment is completed, it enters the electric desalting tank for electric desalination.

[0112] The sound intensity of ultrasonic waves in ultrasonic treatment is 0.03-0.25w / cm 2 , the frequency is 20kHz.

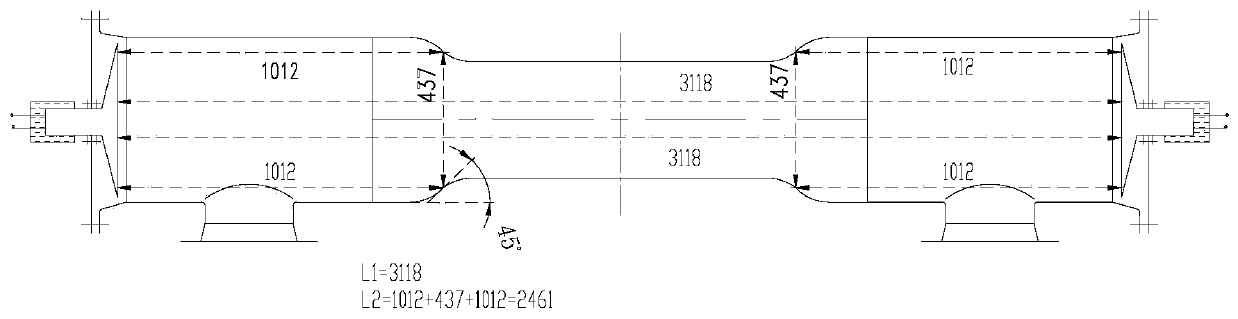

[0113] Ultrasonic action device 12 comprises ultrasonic action area and ultrasonic transducer 6, and ultrasonic action area is the dumbbell-shaped pipeline structure with s...

Embodiment 3

[0133] A method for preventing oil sludge deposition in electric desalination tanks by ultrasonic waves. After mixing crude oil, it enters the ultrasonic device, and in the ultrasonic device, the ultrasonic wave is formed through the structure of the ultrasonic wave area through the structure of the ultrasonic wave. Realize the standing wave field effect, through the formed standing wave field and the no-dead-angle coverage and infinite extension of ultrasonic propagation, the mixed crude oil is ultrasonically treated, and after the treatment is completed, it enters the electric desalting tank for electric desalination.

[0134] The sound intensity of ultrasonic waves in ultrasonic treatment is 0.03-10w / cm 2 , the frequency is 20kHz.

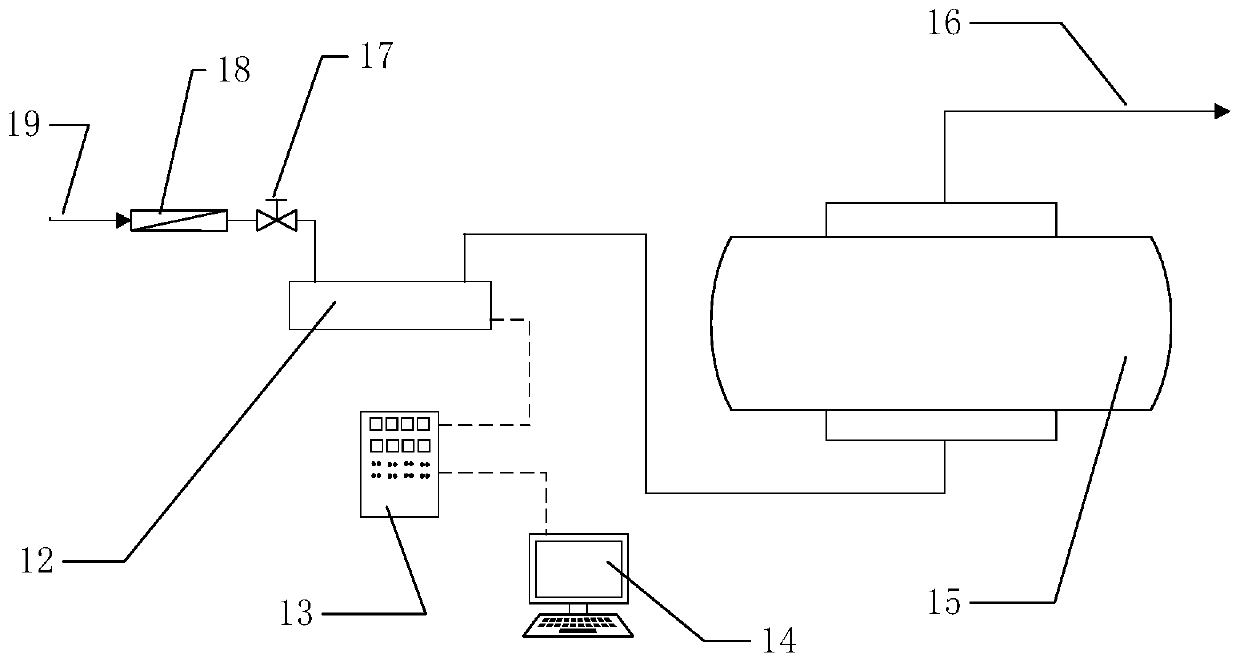

[0135] An ultrasonic device for preventing oil sludge deposition in an electric desalination tank, comprising a crude oil input pipeline 19, a crude oil mixing device is arranged on the crude oil input pipeline 19, the crude oil mixing device is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com