Oxygen vacancy modified metal oxide gas sensitive material for low-concentration NO2 gas detection at low temperature and preparation method thereof

A gas-sensing material, gas detection technology, applied in the preparation of oxide/hydroxide, oxygen/ozone/oxide/hydroxide, chemical instruments and methods, etc., can solve the complex reduction process, weak reduction ability, reduction The problem of high temperature can improve the response recovery time, high sensitivity and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A low-concentration NO 2 A method for preparing a metal oxide porous nanosphere gas-sensing material modified by oxygen vacancies for gas detection, comprising the following steps:

[0047] (1) Dissolve the metal salt raw material in a mixed solvent of organic alcohol; move the obtained clear liquid into a high-pressure reactor, and keep it at 120-200°C for 1 hour, so that the raw material can undergo a compound reaction in a high-temperature and high-pressure environment to obtain a porous Metal oxide precursors.

[0048] (2) Centrifuge the product obtained in step (1), wash it with ethanol for 3-5 times, and dry it at 60-80°C; then calcinate it in a muffle furnace at 400-600°C for 60-120min to obtain a porous metal oxide Nanosphere gas-sensitive material.

[0049] (3) The metal oxide porous nanospheres are placed in a two-chamber tube furnace, the reducing agent is heated at a high temperature in a low pressure environment, and the metal oxide in the low temperature...

Embodiment 1

[0064] 1. Oxygen vacancy modified metal oxide porous nanosphere gas-sensing material and its preparation

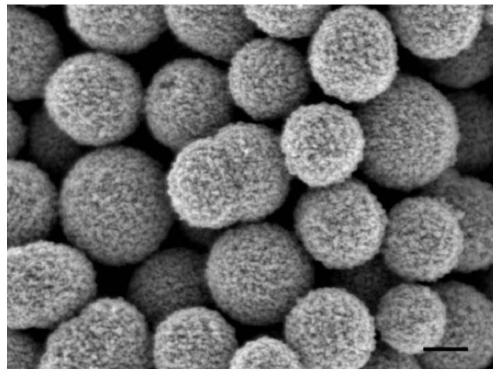

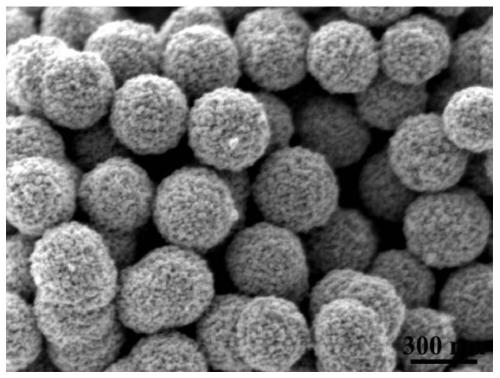

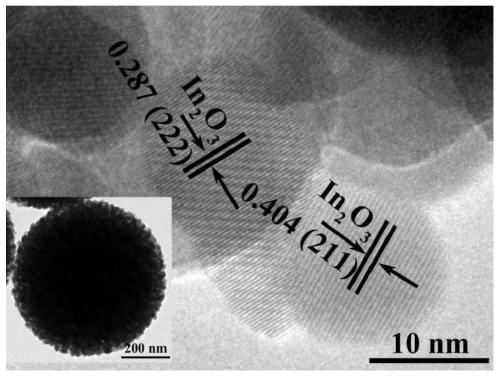

[0065] A low-concentration NO 2 Oxygen vacancies modified metal oxide gas-sensing materials for gas detection, the metal oxide of which is In 2 o 3 Porous nanospheres; In 2 o 3 The porous nanospheres are placed in a two-chamber tube furnace, and the reducing agent is heated at a high temperature under a low pressure environment, and at the same time, the surface reduction treatment is performed on the metal oxide gas-sensitive material at different temperatures, and the reducing agent is metal Al powder. The metal oxide modified by oxygen vacancies is a porous nanosphere composed of small particles, the diameter of the ball is 200-700nm, and the particle size is 10-20nm.

[0066] Preparation steps:

[0067] (1) Add 0.3g of matrix material indium nitrate into a mixed solvent of organic solvent 30ml of isopropanol and 10ml of glycerin and stir until completely dissolve...

Embodiment 2

[0075] Example 2 Gas Sensitive Detection of Oxygen Vacancies Modified Metal Oxides Prepared at Different Reduction Temperatures

[0076] As described in Example 1, the difference is that the reduction temperature of the metal oxide porous nanospheres in step (1) is 250°C, 400°C. At 80℃, 3ppm NO 2 Gas sensitivity test results under gas conditions are as follows: Figure 7 As shown, it can be seen from the figure that with the increase of the surface reduction temperature, the gas-sensing properties of the metal oxide materials modified by oxygen vacancies have certain changes, but all of them are sensitive to 3ppm NO at 80°C. 2 Gas has a relatively good response. The range of its response is 8-86.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com