4D printed polyetheretherketone/niobate compound material and preparation method thereof

A technology of polyether ether ketone and composite materials, which is applied in coatings, medical science, prostheses, etc., and can solve problems such as lumps, high thermal deformation temperature under glass transition temperature load, and no biological activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

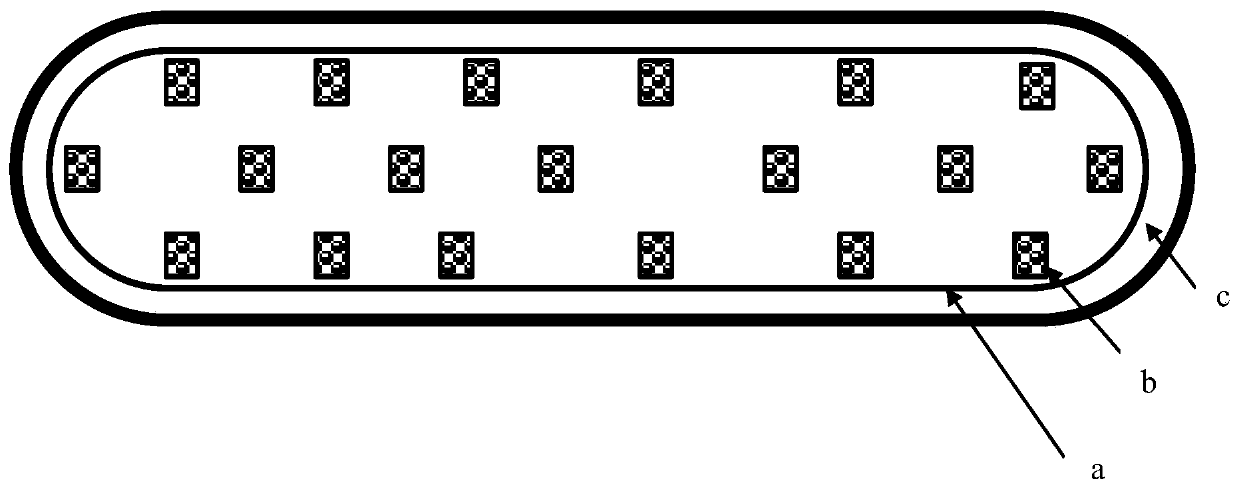

[0021] Dry polyether ether ketone and sodium potassium lithium niobate powder at 120°C for 12 hours respectively, and obtain fibrous polyetheretherketone / sodium potassium lithium niobate composite material by melt coextrusion method, wherein the melt coextrusion chamber temperature is 150°C , the nozzle temperature was 360°C, and the surface of the obtained polyetheretherketone / sodium potassium lithium niobate composite fiber material was coated with PLA / PEG to obtain a PEEK composite material, and the PEEK was formed into the required scaffold structure by 3D printing technology, with a concentration of 95 % of absolute ethanol was washed three times and then washed three times with acetone solution. After ultraviolet sterilization, the body osteoblasts were cultured. Compared with untreated polyether ether ketone fibers under the action of external force, polyether The proliferation and differentiation of cells on the fiber surface of the etherketone composite material is sig...

Embodiment 2

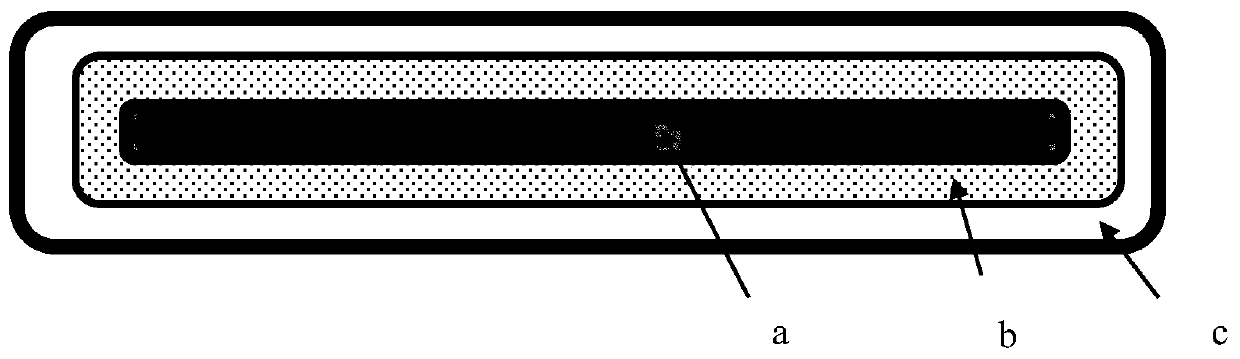

[0023] The polyetheretherketone rod was dried at 125°C for 12h, rinsed three times with 95% absolute ethanol and then washed three times with acetone solution and dried naturally, and deposited on polyetheretherketone by ion beam sputtering deposition (IBAD). The surface of the bar is coated with sodium potassium niobate to obtain polyether ether ketone / sodium potassium lithium niobate composite material, and the surface is coated with PLA, washed three times with 95% absolute ethanol and then washed three times with acetone solution to obtain ether The ether ketone composite material is treated with high temperature and high pressure to make its structure more compact. After ultraviolet sterilization treatment, bone cells are cultured in vitro. The proliferation and differentiation of cells on the surface of the ketone composite rod is significantly improved, the cell adhesion is better, and the biocompatibility is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com