Adsorption-type permeable reaction barrier composite material and preparation method and application thereof

A permeable reactive wall and composite material technology, applied in the field of adsorption-type permeable reactive wall composite material and its preparation, can solve the problems of high material cost, poor structural stability, easy breakage, etc., and achieve high chemical stability and low cost , the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the adsorption type permeable reactive wall composite material of the present invention comprises the following steps:

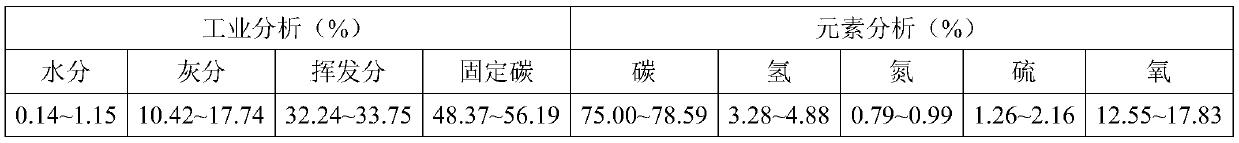

[0027] Step 1, adding the coal liquefaction residue and the oxygen release agent into a container containing semi-coke powder in sequence, and mixing them uniformly to obtain a mixture A; in the mixture A, the content of the coal liquefaction residue is 10% to 30% by mass percentage, The content of oxygen release agent is 2%-5%, the content of semi-coke powder is 65%-88%, the particle size of coal liquefaction residue is 100-300 mesh, and the particle size of semi-coke powder is 100-300 mesh; In terms of parts, its components include 2 to 4 parts of CaO 2 , 1 to 2 parts of MgO 2 and 0.5 parts of Fe 2 o 4 ;

[0028] Step 2, the mixture A prepared in step 1 is pressed into several cylinders with a diameter of 5-10 mm and a height of 8-15 mm through a mold under a pressure of 3-5 MPa;

[0029] Step 3, place the cylinder pre...

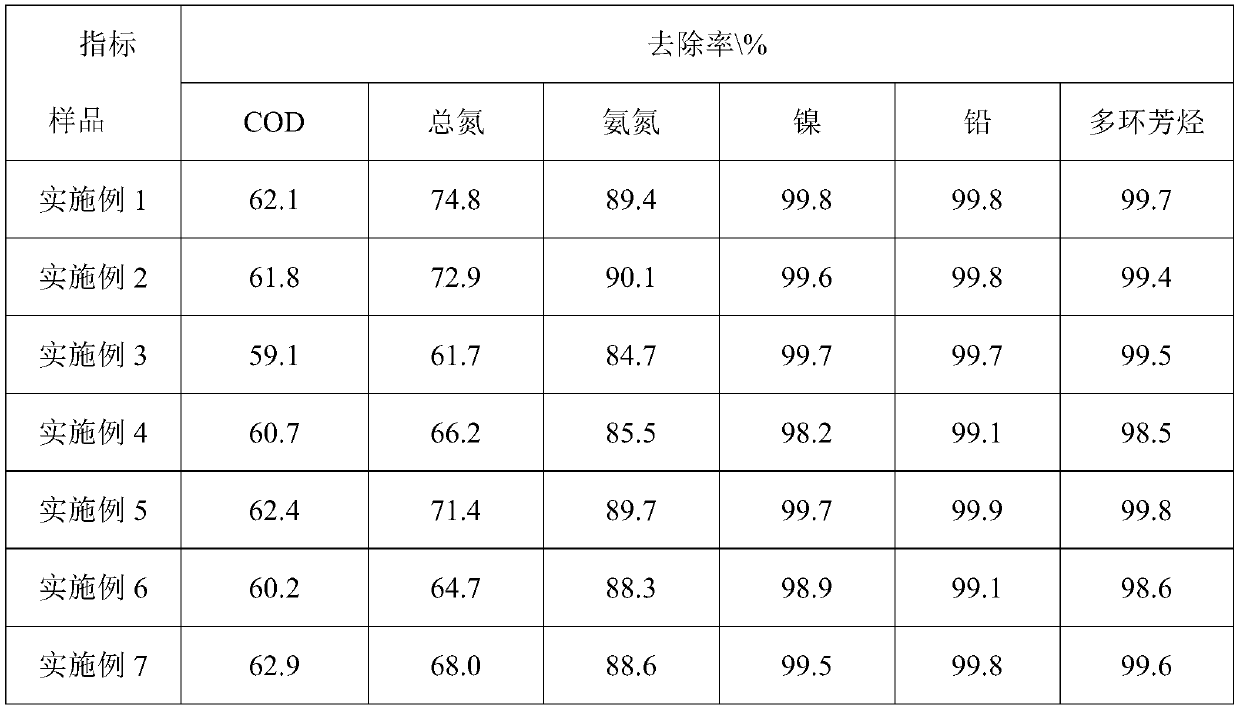

Embodiment 1

[0035] First crush the semi-coke powder and coal liquefaction residue to 200 mesh for later use, then weigh 2 parts of CaO 2 , 1 part of MgO 2 and 0.5 parts of Fe 2 o 4 , mixed evenly, and made into an oxygen release agent for later use. Weigh 10g of coal liquefaction residue (200 mesh) and 2g of oxygen release agent respectively, add them in turn to a beaker containing 88g of blue charcoal powder (200 mesh), and mix well. The mixture was cold-pressed into cylinders with a diameter of 7 mm and a height of 10 mm under a pressure of 5 MPa, and each cylinder had a mass of 0.6 g. Put the cylinder in the tube furnace, set the heating rate at 20°C / s, the final temperature of physical activation at 900°C, the constant temperature time of 120min, CO 2 The gas flow rate is 300mL / min, and the adsorption type permeable reactive wall composite material of the present invention is prepared. The compressive strength of the prepared cylindrical composite material is 4.25MPa, and the iod...

Embodiment 2

[0037] First crush the semi-coke powder and coal liquefaction residue to 200 mesh for later use, then weigh 2 parts of CaO 2 , 1 part of MgO 2 and 0.5 parts of Fe 2 o 4 , mixed evenly, and made into an oxygen release agent for later use. Weigh 20g of coal liquefaction residue (200 mesh) and 4g of oxygen release agent respectively, add them in turn to a beaker containing 76g of blue charcoal powder (200 mesh), and mix well. The mixture was cold-pressed into cylinders with a diameter of 7 mm and a height of 10 mm under a pressure of 5 MPa, and each cylinder had a mass of 0.6 g. Put the cylinder in the tube furnace, set the heating rate at 20°C / s, the final temperature of physical activation at 900°C, the constant temperature time of 120min, CO 2The gas flow rate is 300mL / min, and the adsorption type permeable reaction wall composite material of the present invention is prepared. The compressive strength of the prepared cylindrical composite material is 5.51 MPa, and the iod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com