Aqueous-phase synthesis covalent organic framework material and preparation method thereof

A technology of covalent organic framework and water phase, which is applied in the field of covalent organic framework materials, can solve the problems of high cost, hindered application, complex operation and other problems of ionic liquids, and achieve the effect of easy industrial production, convenient operation and good universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Synthesis of Covalent Organic Framework Material JUC-520

[0029] 1,3,5-tris(3-dimethylamino-1-acetyl-2-enyl)benzene (18.5 mg, 0.05 mmol) and 2,4,6-tris(4-aminophenyl)-1 , 3,5-triazine (17.7mg, 0.05mmol) was ground in a mortar for 1 minute, the mixture was put into a 10mL PE centrifuge tube, and glacial acetic acid (0.4mL) and water (4mL) were added. The system was placed in the air at room temperature for 3 hours, and a yellow fluffy solid was observed to form. Suction filter and wash with 100mL of N,N-dimethylformamide and acetone respectively. Finally, the filtered solid was dried overnight in a vacuum oven at 80°C to obtain a yellow solid product (87% yield).

[0030] The synthesis steps of the intermediate 1,3,5-tris(3-dimethylamino-1-acetyl-2-enyl)benzene are as follows: 1,3,5-triacetylbenzene (0.82g, 4.0 mmol) and N,N-dimethylformamide diethyl acetal (2.4 g, 12.0 mmol) were dissolved in 10.0 ml N,N-dimethylformamide and stirred at 90° C. under dry nitrogen for...

Embodiment 2

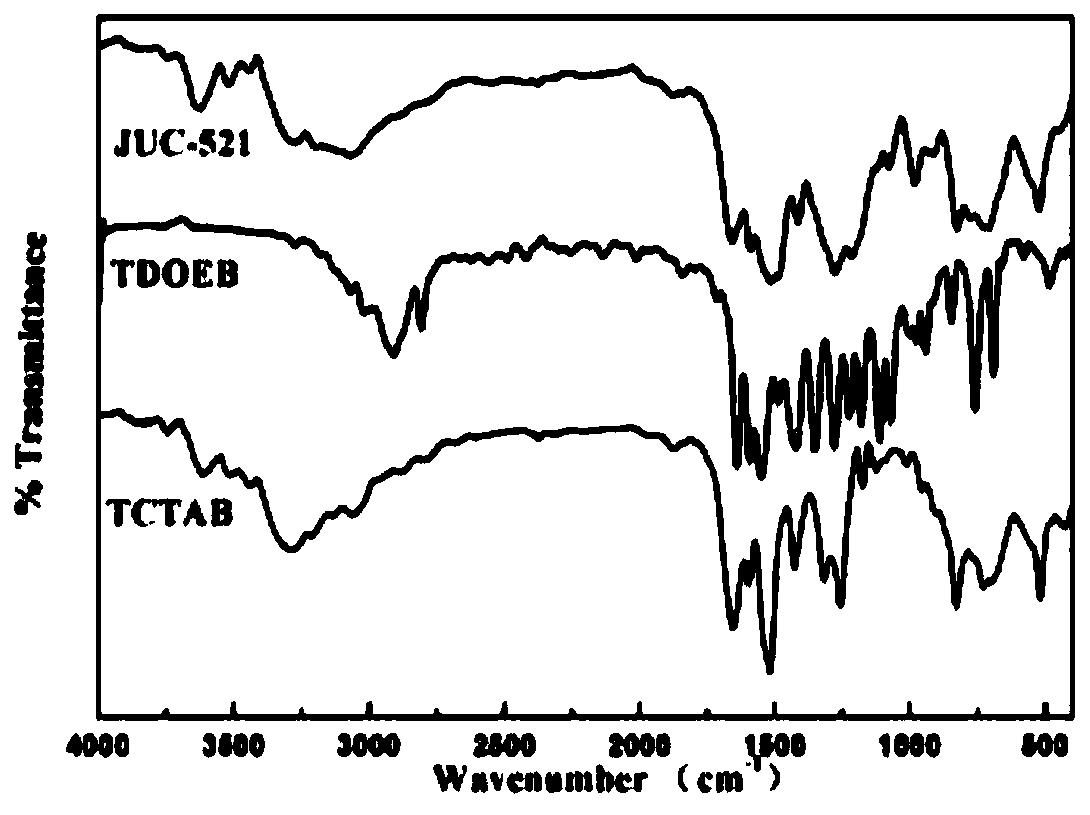

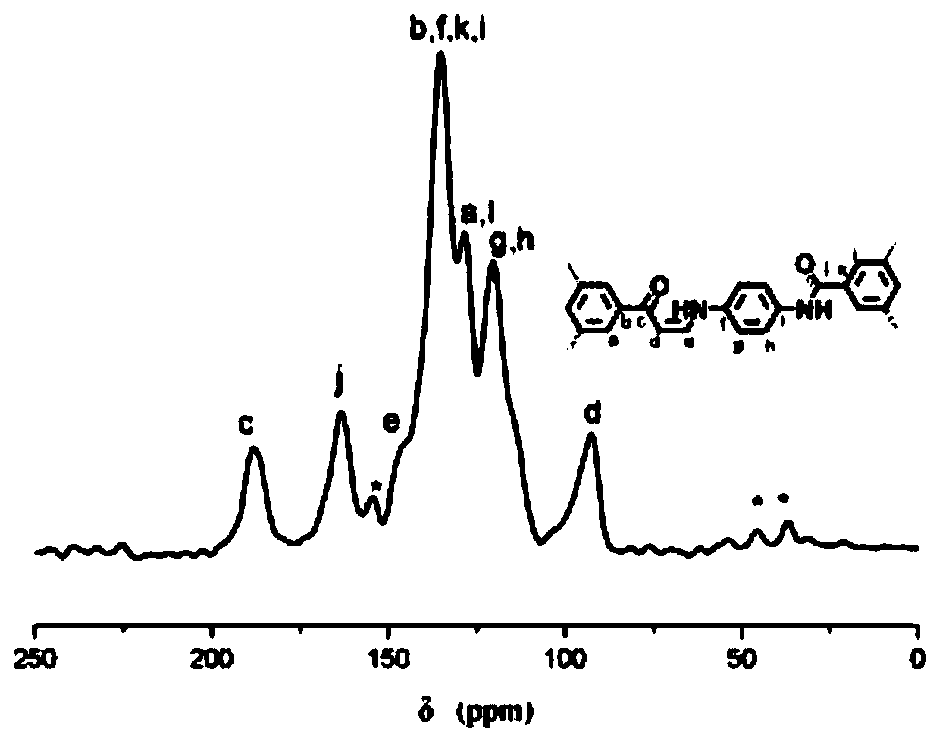

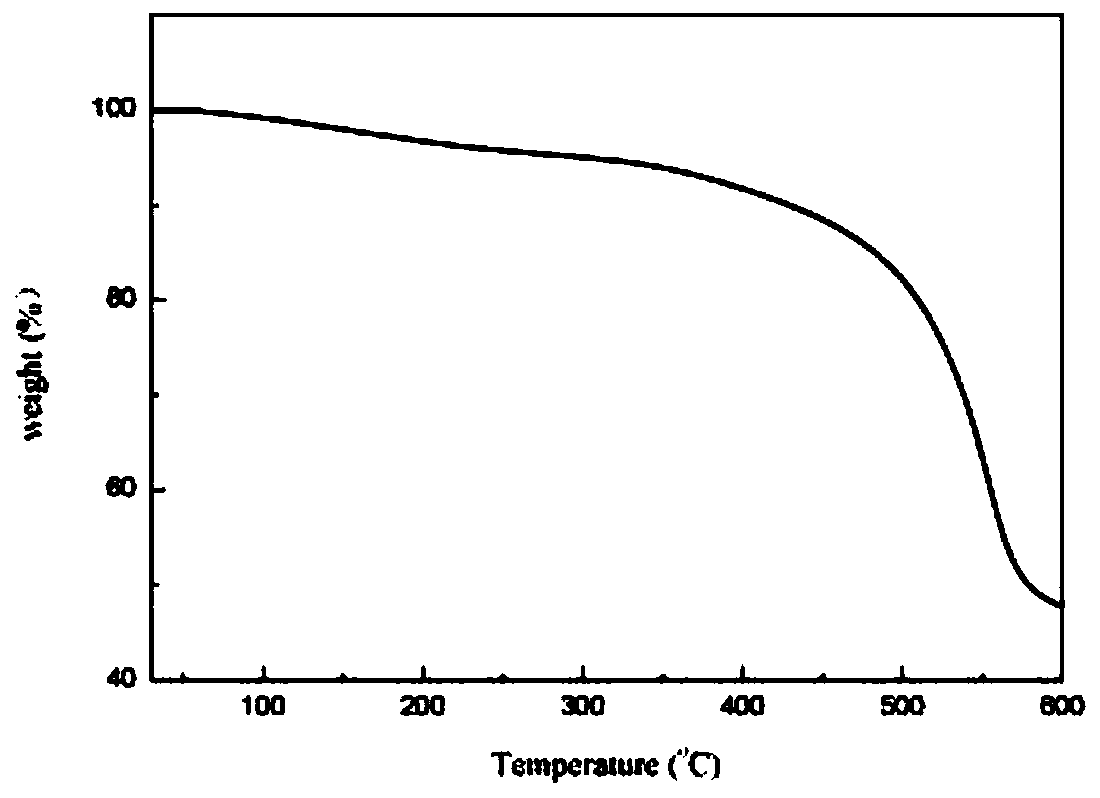

[0032]Synthesis of Covalent Organic Framework Material JUC-521

[0033] 1,3,5-tris(3-dimethylamino-1-acetyl-2-enyl)benzene (18.5mg, 0.05mmol) and 1,3-5-tricarboxylic acid tris(4-aminobenzene Amide)benzene (24.0 mg, 0.05 mmol) was ground in a mortar for 1 minute, the mixture was put into a 10 mL PE centrifuge tube, and 6 mol / mL acetic acid solution (4.0 mL) was added.

[0034] The system was placed in the air at room temperature for 0.5 hours to react, and a yellow fluffy solid was observed to form. Suction filter and wash with 100mL of N,N-dimethylformamide and acetone respectively. Finally, the filtered solid was dried overnight in a vacuum oven at 80°C to obtain a yellow solid product (95% yield). If you need a large-scale experiment, you only need to double the current equivalent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com