Crude gas waste heat recycling and use system and method

A waste heat recovery system and waste heat recovery technology, applied in the field of coke oven gas waste heat recovery, can solve problems such as unreasonable use of waste heat from waste gas, and achieve the effects of eliminating hidden dangers in production safety, significant economic benefits, and saving coke oven gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

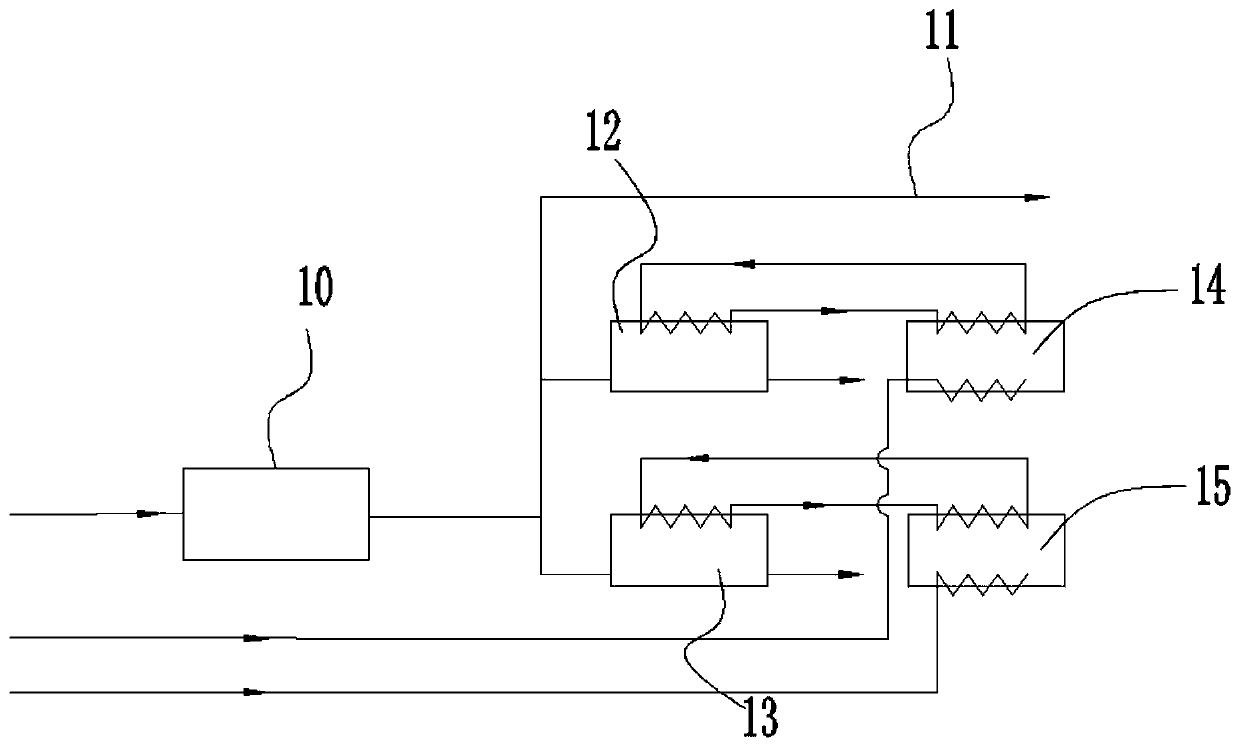

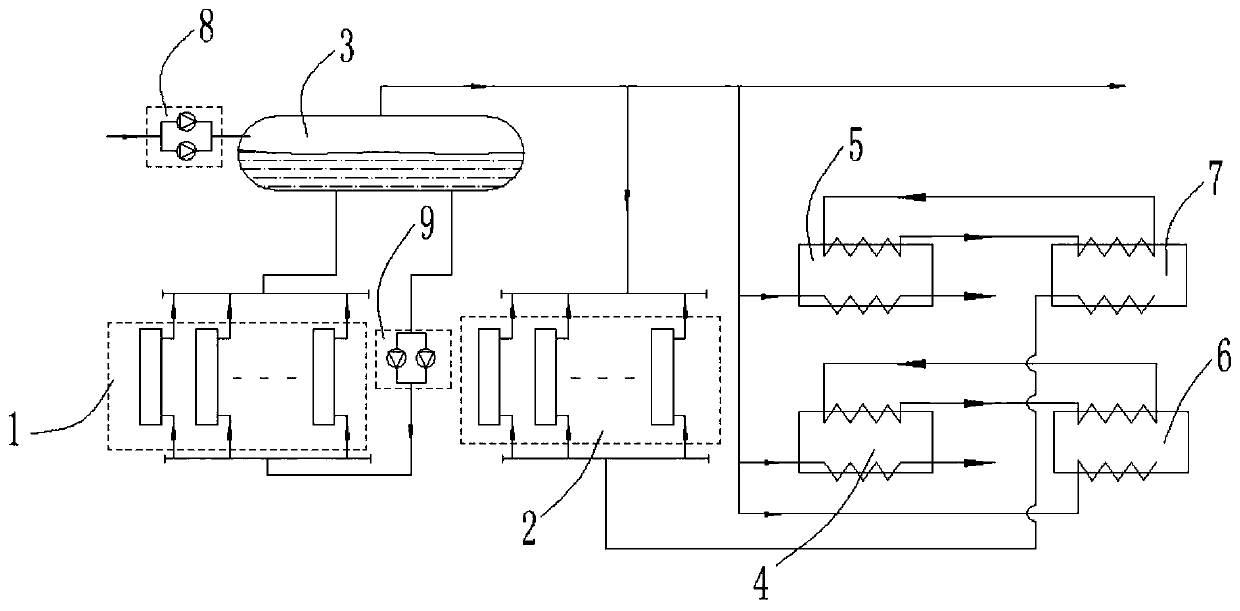

[0037] Embodiment 1 of the present invention provides a high-temperature raw gas waste heat recovery and utilization system, such as figure 2 shown.

[0038]The raw gas waste heat recovery and utilization system of the present invention includes two parts: a waste heat recovery system and a waste heat utilization system. The waste heat recovery system includes a saturated steam heat exchanger group 1, a superheated steam heat exchanger group 2, and a steam drum 3 with a steam-water separator And feed water pump group 8 and circulating water pump group 9; waste heat utilization system includes condensed ammonia water heater 4, condensed oil-rich heater 5, ammonia distillation tower 6 and debenzene tower 7; the water inlet of saturated steam heat exchanger group 1 passes through the circulation The water pump group 9 is connected to the water outlet of the steam drum 3, the water outlet of the saturated steam heat exchanger group 1 is connected to the first water inlet of the s...

Embodiment 2

[0045] Embodiment 2 of the present invention provides a method for recovering waste heat from raw coal gas, comprising the following steps:

[0046] Step 1. The water in the steam drum 3 is transported to the saturated steam heat exchanger group 1 through the circulating water pump group 9, and the mixture of saturated steam and water generated after heat exchange by the saturated steam heat exchanger group 1 passes through the steam drum 3. The first water inlet returns to the steam drum 3;

[0047] Step 2: Transport part of the saturated steam generated in the steam drum 3 through the gas-liquid separator to the waste heat utilization system through the steam pipe network to provide heat energy for the condensed ammonia water heater 4, the condensed oil-rich heater 5 and the ammonia distillation tower 6; The condensed water separated after heat exchange between the steam and the condensed ammonia water heater 4 and the condensed oil-rich heater 5 is returned to the steam dru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com