High frequency and low dielectric constant low temperature co-fired ceramic material and preparation method

A technology of low-temperature co-fired ceramics and low dielectric constant, applied in the field of electronic materials, can solve the problems of low bending strength, high dielectric loss, and limited application of quartz materials, and achieve high bending strength, low dielectric constant, Good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

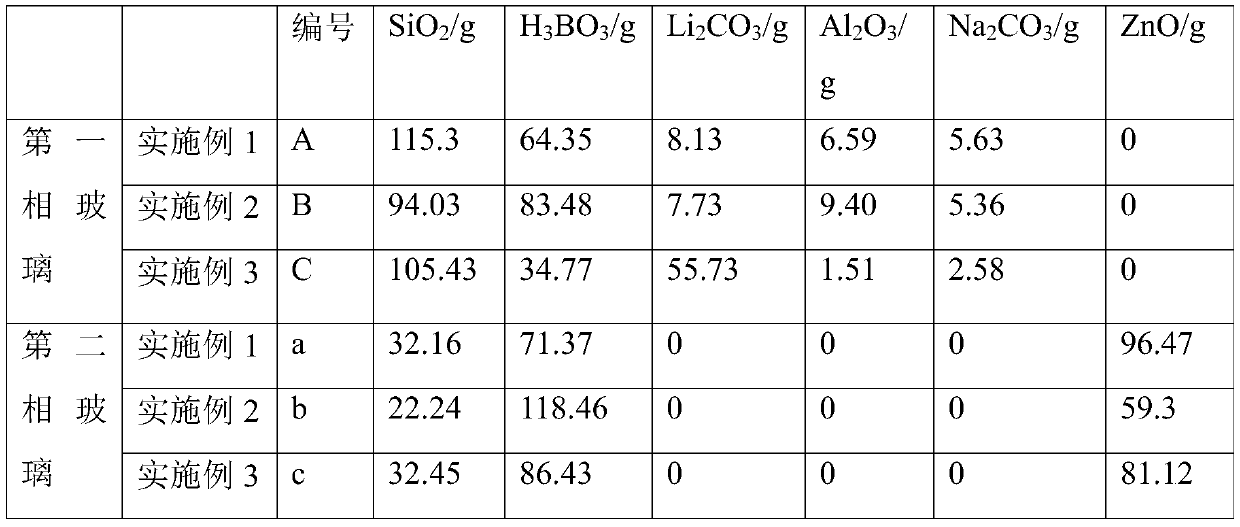

[0031] Embodiment 1-3 is the preparation of glass powder

[0032] 1) Weigh a certain mass of SiO 2 , H 3 BO 3 , Li 2 CO 3 , Al 2 o 3 , Na 2 CO 3As the raw material powder of the first phase glass, dry mix for 12 hours, put the evenly mixed raw material powder into a crucible, put it in a high-temperature resistance furnace at 1450°C for melting and clarification, and pour the clarified glass liquid quickly after 0.5 hours In deionized water, glass crumbs were obtained. Crush the broken glass slag, put it into a ball mill jar, use absolute ethanol as a medium, ball mill it to a medium particle size of 2.5-3.5 μm, and dry it to obtain glass powder. The glasses prepared in Examples 1-3 are respectively recorded as the first phase glasses A, B, and C, as shown in Table 1 below.

[0033] 2) Weigh a certain mass of SiO 2 , H 3 BO 3 , ZnO is used as the raw material powder of the second phase glass, and the glass powder is prepared by the same method as the first phase g...

Embodiment 4-9

[0037] Embodiment 4-9 is the preparation of low temperature co-fired ceramic powder

[0038] Weigh the first phase glass, second phase glass, SiO 2 , ZrO 2 The material is composed of ethanol as a solvent, ball milled for 2-8 hours and then dried to obtain low temperature co-fired ceramic powder.

[0039] Table 2

[0040] serial number First phase glass / g Second phase glass / g SiO 2 / g

Embodiment 10-15

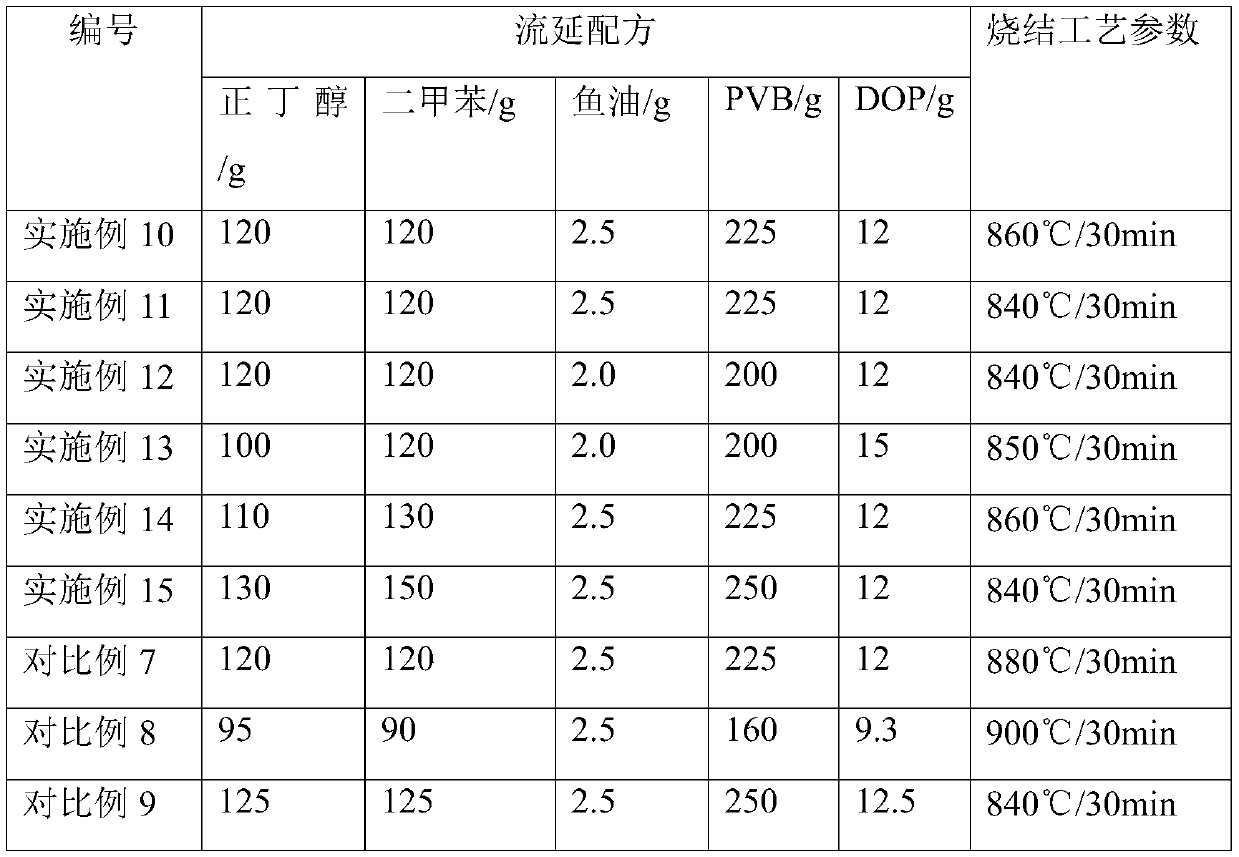

[0042] Examples 10-15 are prepared from the low-temperature co-fired ceramic powders given in Examples 4-9 and the proportions of the components of the ceramic slurry listed in Table 3 below to prepare low-temperature co-fired ceramic material green tapes and sintering process parameters.

[0043] table 3

[0044]

[0045] 1) Weigh 250g of low-temperature co-fired ceramic powder, add n-butanol and xylene as a solvent, use fish oil as a dispersant, disperse the low-temperature co-fired ceramic powder for 17 hours, and then add 20% binder PVB and phthalic acid Dizinc ester (DOP) is used as a plasticizer, and after being mixed for 5 hours, the material is degassed to obtain a low-temperature co-fired ceramic slurry, and a green ceramic tape is obtained by casting equipment.

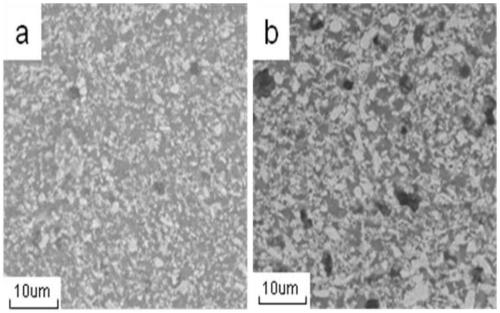

[0046] 2) Cutting, lamination, isostatic pressing, and slicing of raw porcelain strips to obtain 7.5mm*7.5mm*1mm tiles and 45mm*5mm*4.5mm rectangular tiles, and place the tiles and tiles in a box Debindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com