Flame retarding and overcharging prevention electrolyte additive and electrolyte containing electrolyte additive

An electrolyte additive, anti-overcharge technology, applied in organic electrolytes, non-aqueous electrolytes, circuits, etc., to achieve good protection effect, low electrochemical performance, and reduce the total usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

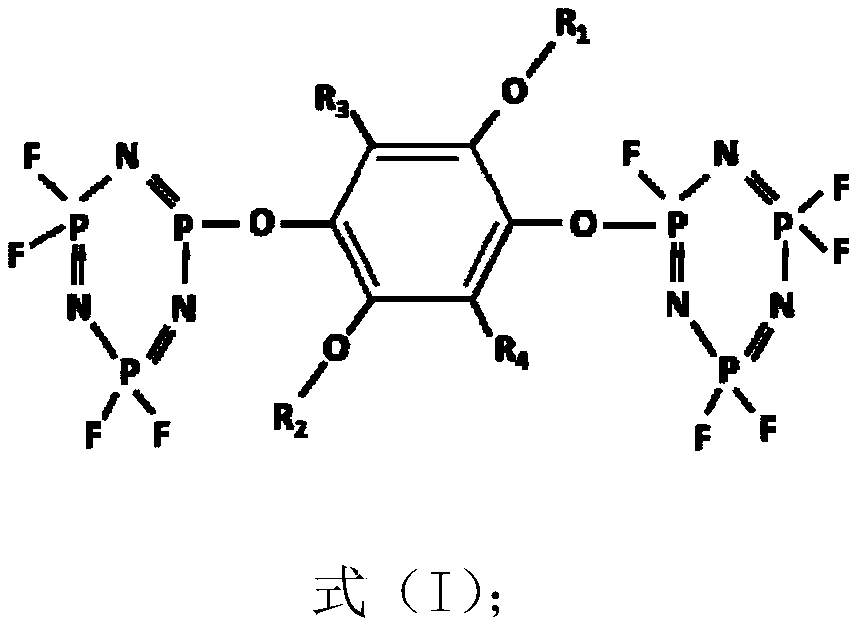

[0032] Prepare additive, concrete steps are as follows:

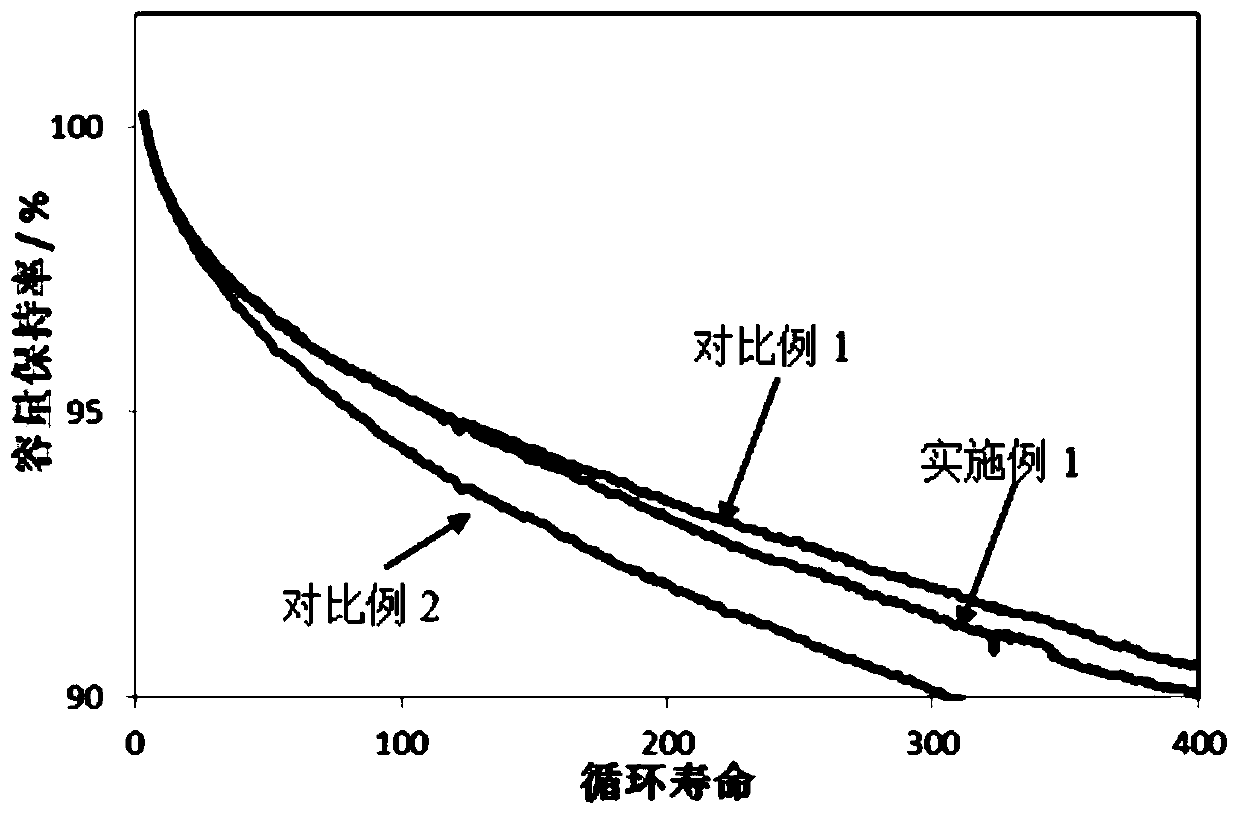

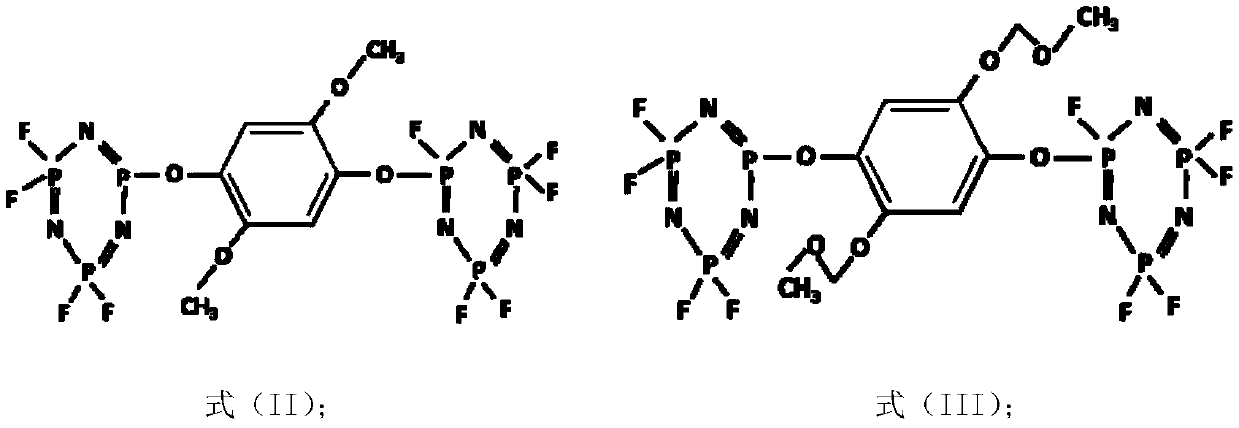

[0033] In the there-necked flask of 2000ml equipped with electric stirrer, reflux condenser, thermometer, add organic solvent n-hexane 600g, reactant hexafluorocyclotriphosphazene 600g and 2,4-dimethoxy hydroquinone 300g, And add main catalyst KI6g, deacidification agent sodium carbonate 15g, reaction temperature is controlled at 25 ℃, reacts 10 hours, obtains reaction solution after reaction finishes; Reactant solution is filtered to obtain filtrate, and filtrate rectification obtains target product high purity (99.5%) Cyclic triphosphazene p-phenylene ether compound additive, structure as shown in formula (II):

[0034]

[0035] Prepare the electrolyte, the specific steps are as follows:

[0036] In an argon glove box with moisture content ≤ 10ppm, mix ethylene carbonate (EC) and ethyl methyl carbonate (EMC) according to the mass ratio EC:EMC=3:7 to obtain an organic solvent, and then slowly Add lithium hexafluor...

Embodiment 2

[0041] Prepare formula (II) additive according to the method of embodiment 1; Prepare electrolyte 2 and experimental battery 2 by the method of embodiment 1 equally; Difference is in electrolyte 2, lithium hexafluorophosphate, organic solvent, vinylene sulfate and formula (II) The mass fractions of additives are 13.5%, 75%, 1.5%, and 10%, respectively.

Embodiment 3

[0043] Prepare additive, concrete steps are as follows:

[0044] In a 2000ml three-necked flask equipped with an electric stirrer, a reflux condenser, and a thermometer, add 600g of organic solvent acetonitrile, 600g of reactant hexafluorocyclotriphosphazene and 2,4-bis-methoxymethyleneoxy-p-phenylene Diphenol 300g, and add main catalyst KI 6g, deacidifying agent potassium carbonate 15g, reaction temperature is controlled at 25 ℃, reacts for 10 hours, obtains reaction liquid after reaction finishes; Purity (99.5%) cyclotriphosphazene p-phenylene ether compound additive, the structure is as shown in formula (III):

[0045]

[0046]

[0047] Using the additive of formula (III), prepare electrolyte 3 and experimental battery 3 according to the method of Example 1; the difference is that in electrolyte 3: the mass fractions of lithium hexafluorophosphate, organic solvent, vinylene carbonate and the additive of formula (III) are respectively 13.5 %, 80%, 1.5%, 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com