An integrated sic solid state power controller

A solid-state power and controller technology, which is applied in the fields of printed circuit manufacturing, printed circuit precursor manufacturing, support structure installation, etc., can solve problems affecting circuit work efficiency and electromagnetic performance, small integrated SSPC modules, and damage to the copper layer of power devices Problems such as routing, to achieve the effect of improving work reliability, high mechanical strength, and reducing parasitic parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

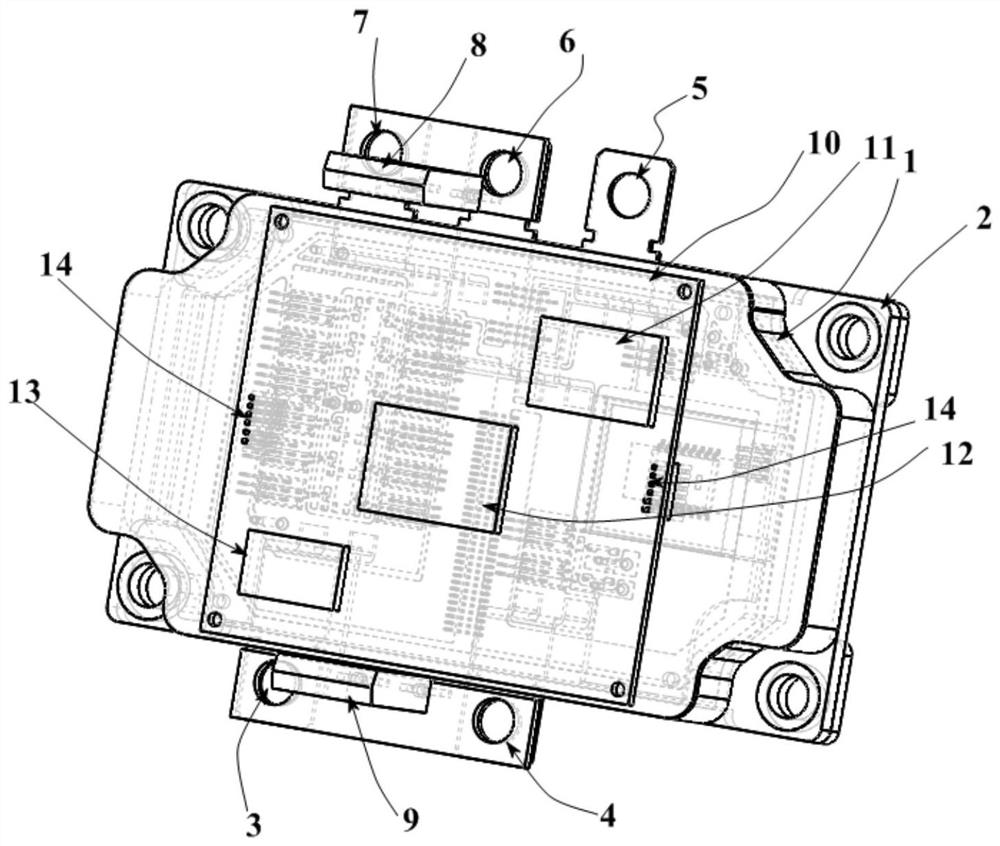

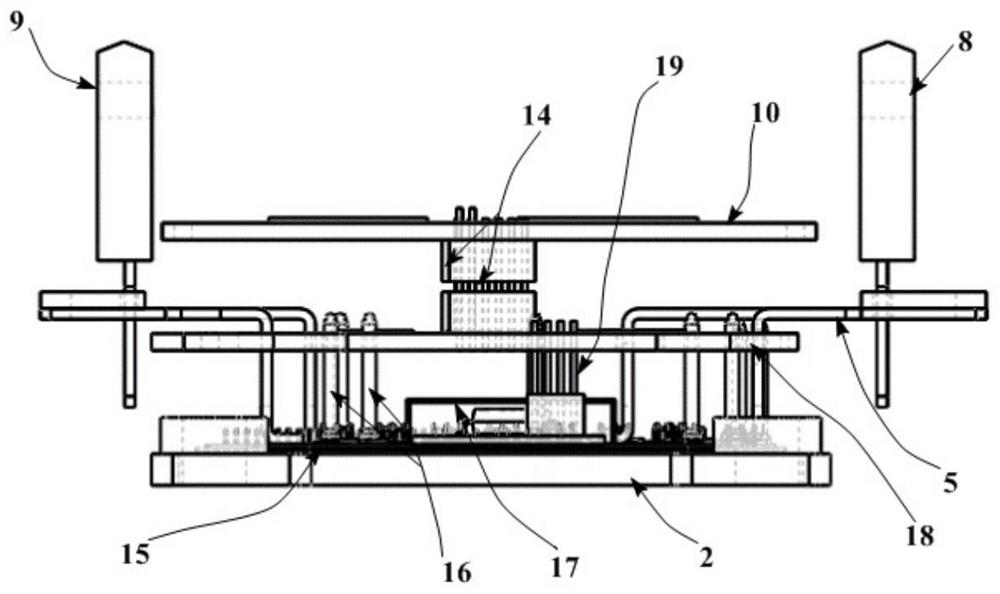

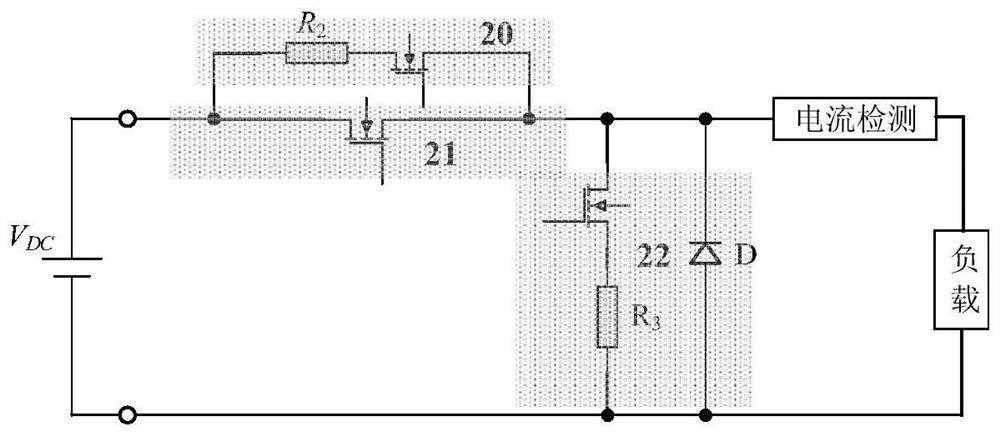

[0031] Such as figure 1 Shown is the 3D appearance structure diagram of the present invention. It can be seen from the figure that the integrated SiC solid-state power controller is led from the casing 1, the substrate 2, and the power terminals (3, 4, 5, 6, 7) and power terminals outside the casing. The resistor (bleeder resistor 8, current limiting resistor 9), the circuit structure inside the shell and the digital circuit board 10 installed on the shell are composed. The power resistors 8 and 9 are placed outside the casing 1, which is beneficial to the installation of large-volume and high-power power resistors in the integrated SSPC module and the heat dissipation of the power resistors. Shell 1 is made of aluminum alloy material with high thermal conductivity, and substrate 2 is made of AlSiC material with low thermal expansion coeff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com