High-nickel pentlandite phase nickel and cobalt sulfide electrocatalyst for alkaline water electrolysis, and preparation method thereof

A technology of pentlandite and sulfide electricity, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, electrolysis processes, etc., can solve the problems of low catalytic performance of water electrolysis, improve electrocatalytic activity, and improve electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In 40mL0.025mol / L Co(NO 3 ) 2 ·6H 2Add 1mL of ethylenediamine to the O solution, stir for 30 minutes, and after obtaining a complex solution, add chopped 0.1g foam nickel flakes to the mixed solution, and then add 10mL of 0.1mol / L nickel foam dropwise to the obtained mixed solution After mixing the thiourea solution, transfer the solution to a 100mL polytetrafluoroethylene hydrothermal reactor. Put the reaction kettle into a blast oven, react at 180°C for 12 hours, cool to 25°C after the reaction, take out the reaction kettle and use a centrifuge to separate the solid product, wash / centrifuge alternately for 4 times, and put the solid product into a vacuum drying at 80° C. for 12 hours in an oven to obtain the nickel-cobalt sulfide electrocatalyst of the present invention.

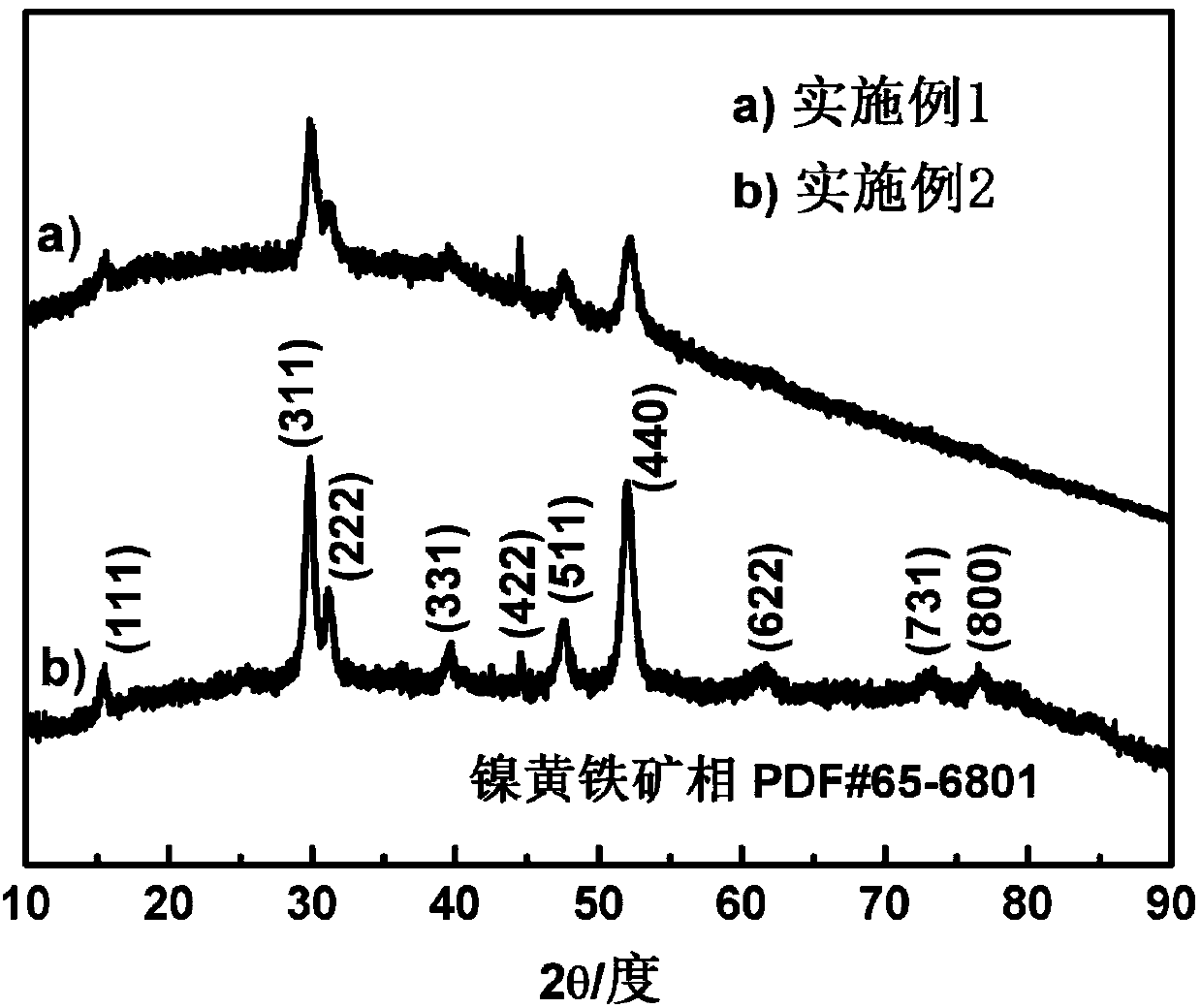

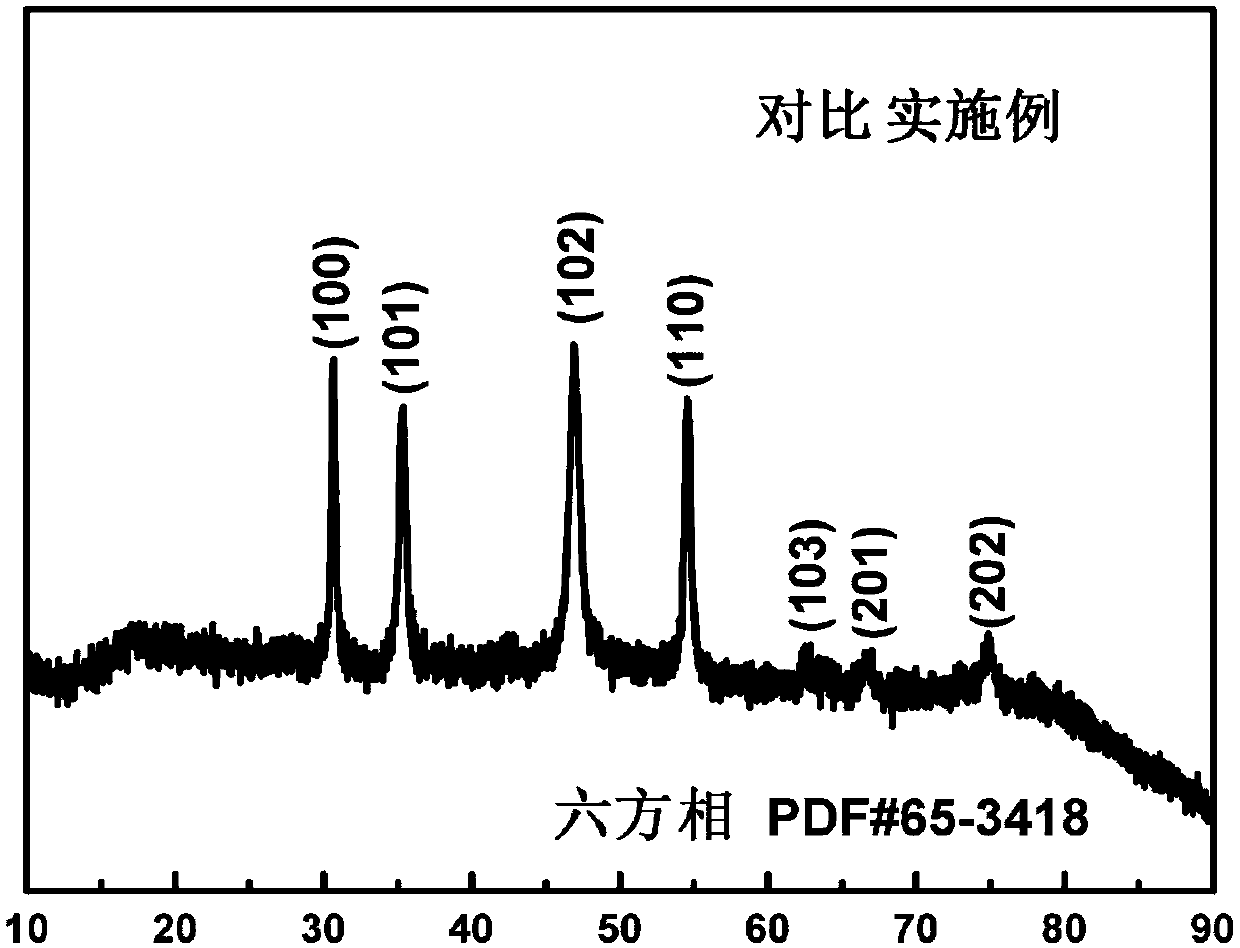

[0023] The phase structure of the prepared nickel-cobalt sulfide electrocatalyst is a pentlandite phase. The elemental analysis results show that the Ni / Co atomic ratio in the electrocatalyst is ...

Embodiment 2

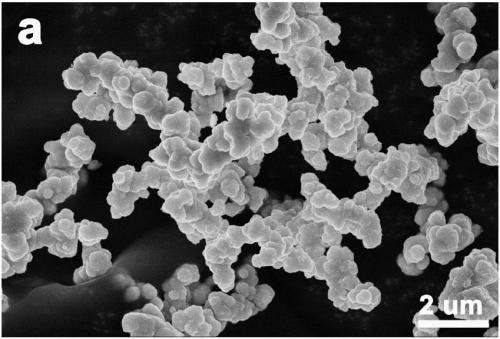

[0029] In 80mL 0.025mol / L Co(NO 3 ) 2 ·6H 2 Add 1 mL of ethylenediamine to the O solution, stir for 30 minutes, and after obtaining a complex solution, add 0.1 g of metal nickel powder to the mixed solution, and then add 20 mL of 0.1 mol / L thiourea dropwise to the obtained mixed solution Solution, after mixing evenly, transfer the solution into a 200mL polytetrafluoroethylene-content hydrothermal reactor. Put the reaction kettle into a blast oven, react at 180°C for 12 hours, cool to 25°C after the reaction, take out the reaction kettle and use a centrifuge to separate the solid product, wash / centrifuge alternately for 4 times, and put the solid product into a vacuum drying at 80° C. for 12 hours in an oven to obtain the nickel-cobalt sulfide electrocatalyst of the present invention.

[0030] The phase structure of the prepared nickel-cobalt sulfide electrocatalyst is a pentlandite phase. The elemental analysis results show that the Ni / Co atomic ratio in the electrocatalyst...

Embodiment 3

[0032] In 80mL 0.025mol / L Co(NO 3 ) 2 ·6H 2 Add 1 mL of ethylenediamine to the O solution, stir for 30 minutes, and after obtaining a complex solution, add 0.15 g of chopped foamed nickel to the mixed solution, and then add 20 mL of 0.1 mol / L nickel Thiourea solution, after mixing evenly, transfer the solution into a 200mL polytetrafluoroethylene-content hydrothermal reactor. Put the reaction kettle into a blast oven, react at 180°C for 24 hours, cool to 25°C after the reaction, take out the reaction kettle and use a centrifuge to separate the solid product, wash / centrifuge alternately for 4 times, and put the solid product in a vacuum drying at 80° C. for 12 hours in an oven to obtain the nickel-cobalt sulfide electrocatalyst of the present invention.

[0033] The phase structure of the prepared nickel-cobalt sulfide electrocatalyst is a pentlandite phase. The elemental analysis results show that the Ni / Co atomic ratio in the electrocatalyst is 1.28, with a high Ni doping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com