Water-based single-component air-dry paint used for machines and production method of water-based single-component air-dry paint used for machines

A single-component, self-drying paint technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of insufficient protection of materials, harmful to human body and environment, and high VOC value, so as to improve corrosion resistance, prevent oxygen erosion, and VOC low value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

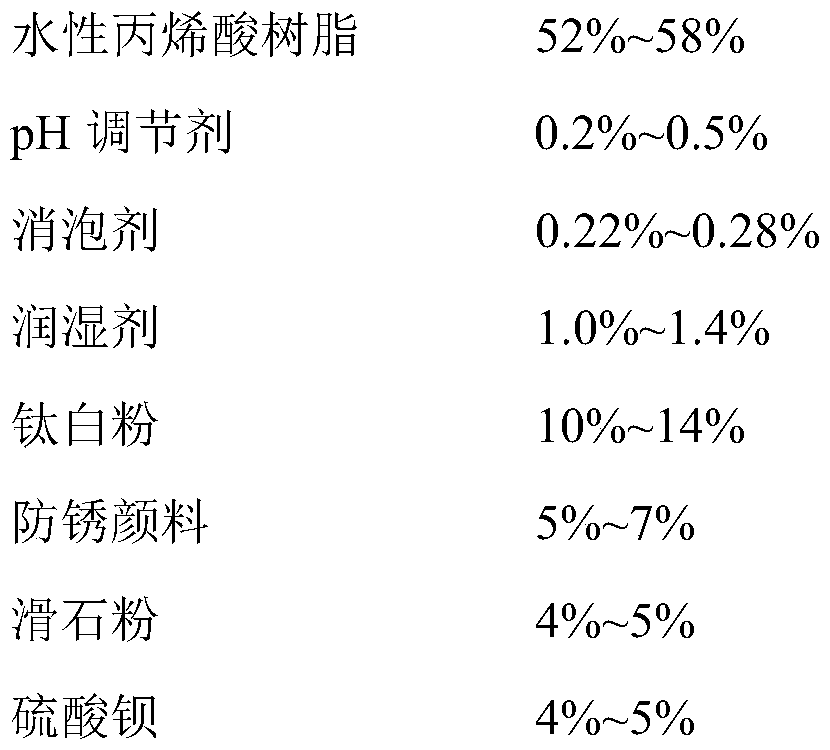

[0038] A water-based one-component self-drying paint for machinery, which is made of the following raw materials in weight percentage:

[0039]

[0040] In this embodiment, the antirust pigment is zinc phosphate.

[0041] In this embodiment, the glass transition temperature of the water-based acrylic resin is 55° C., and the solid content is 47%.

[0042] In this embodiment, the defoamer is a water-based silicone defoamer.

[0043] Wherein, the wetting agent is polyether modified siloxane;

[0044] In this embodiment, the film-forming aid is isopropanol.

[0045] Wherein, the thickener is an associative polyurethane thickener.

[0046] The preparation method of above-mentioned a kind of water-based one-component mechanical self-drying paint, it comprises the following steps:

[0047] Step 1. Prepare the first mixture: add the formula amount of water, wetting agent, defoamer, pH regulator, titanium dioxide, anti-rust pigment, barium sulfate, talcum powder and calcium car...

Embodiment 2

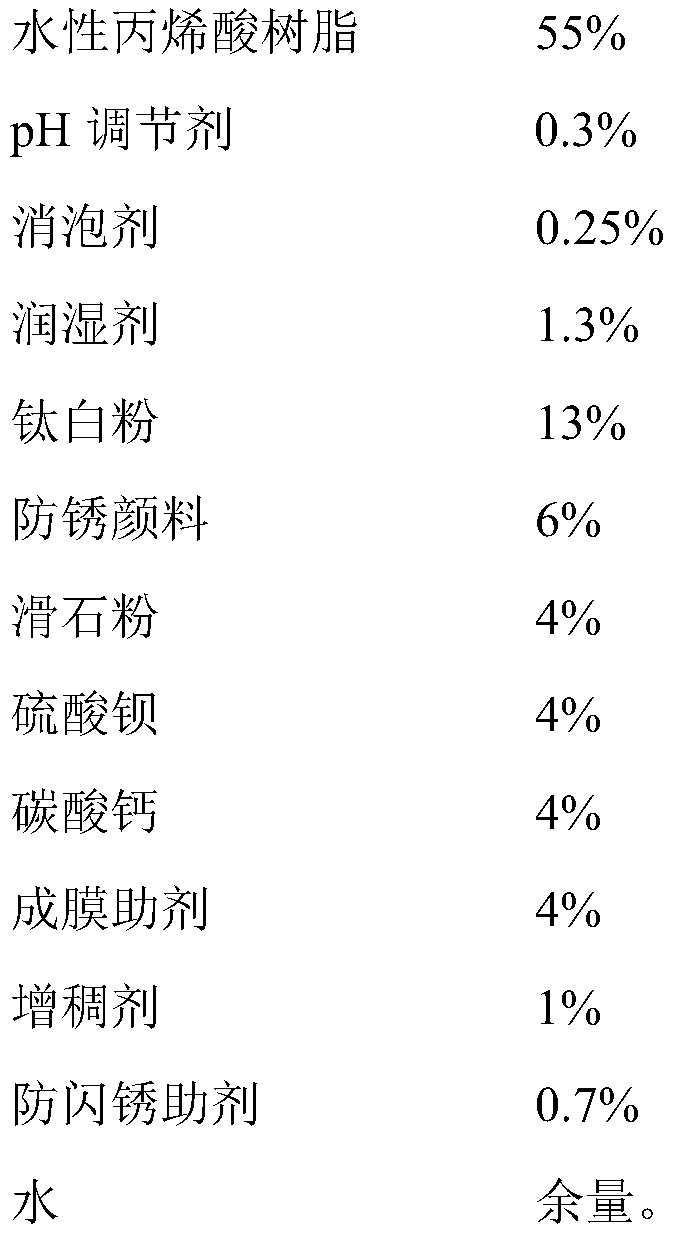

[0052]

[0053] In this embodiment, the antirust pigment is aluminum tripolyphosphate.

[0054] In this embodiment, the glass transition temperature of the water-based acrylic resin is 50° C., and the solid content is 45%.

[0055] In this embodiment, the defoamer is a mineral oil defoamer.

[0056] Wherein, the wetting agent is polyether modified siloxane;

[0057] In this embodiment, the film-forming aid is dipropylene glycol butyl ether.

[0058] Wherein, the thickener is an associative polyurethane thickener.

[0059] The preparation method of above-mentioned a kind of water-based one-component mechanical self-drying paint, it comprises the following steps:

[0060] Step 1. Prepare the first mixture: add the formula amount of water, wetting agent, defoamer, pH regulator, titanium dioxide, anti-rust pigment, barium sulfate, talcum powder and calcium carbonate in the container, and then at a speed of 550rpm Stir for 20min to obtain the first mixture;

[0061] Step 2,...

Embodiment 3

[0065]

[0066] In this embodiment, the antirust pigment is a combination of zinc aluminum phosphate and zinc molybdate.

[0067] In this embodiment, the glass transition temperature of the water-based acrylic resin is 60° C., and the solid content is 50%.

[0068] In this embodiment, the defoamer is a combination of water-based silicone defoamer and mineral oil defoamer.

[0069] Wherein, the wetting agent is polyether modified siloxane;

[0070] In this embodiment, the film-forming aid is a composition of dipropylene glycol butyl ether and dipropylene glycol methyl ether.

[0071] Wherein, the thickener is an associative polyurethane thickener.

[0072] The preparation method of above-mentioned a kind of water-based one-component mechanical self-drying paint, it comprises the following steps:

[0073] Step 1. Prepare the first mixture: add the formula amount of water, wetting agent, defoamer, pH regulator, titanium dioxide, anti-rust pigment, barium sulfate, talcum pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com