Preparation method for lignin/resin superhydrophobic insulating and corrosion-resistant coating

A super-hydrophobic and corrosion-resistant technology, used in lignin coatings, epoxy resin coatings, anti-corrosion coatings, etc., can solve the problems of wasting resources and polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

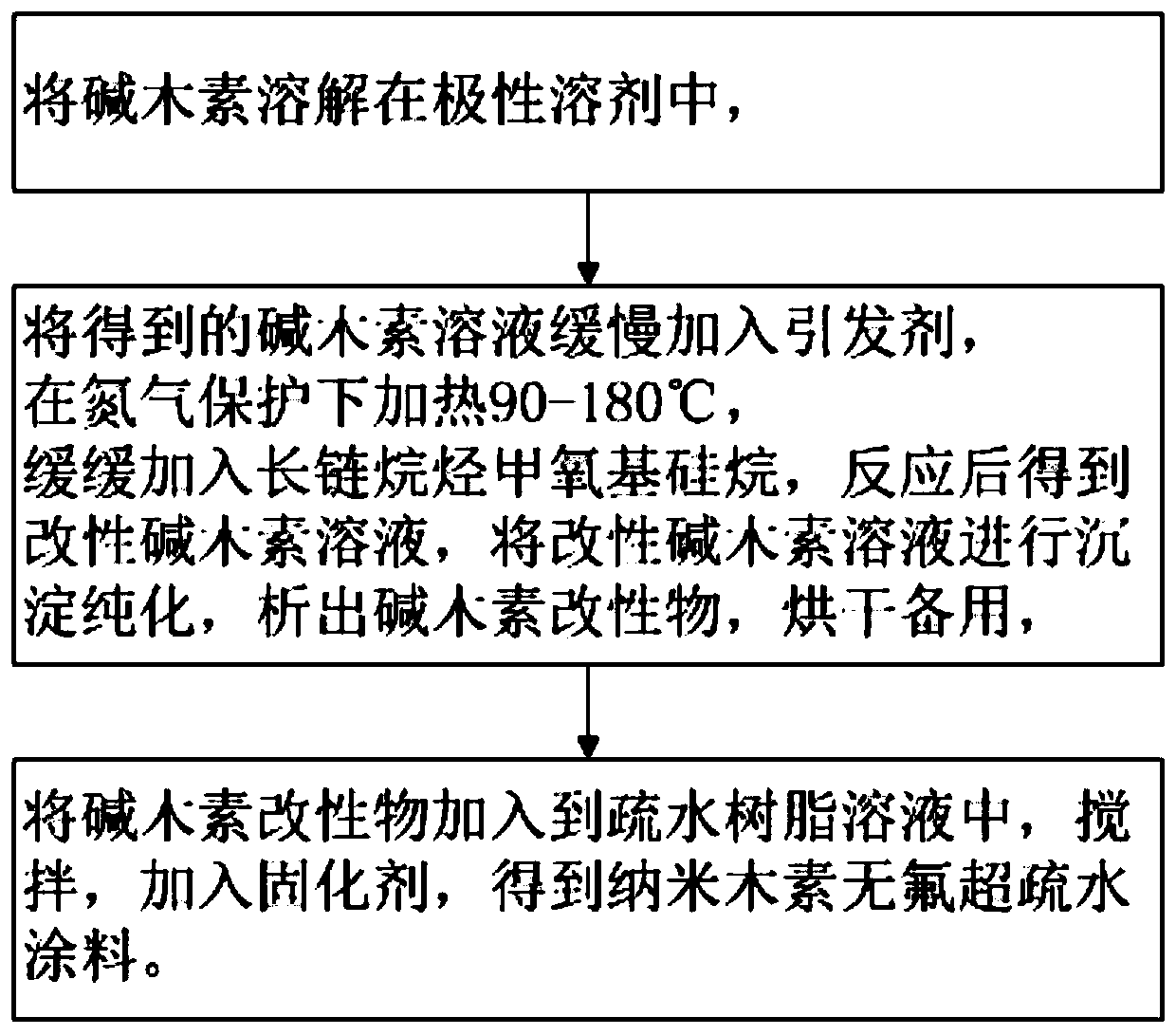

[0032] The invention provides a preparation method of a lignin / resin superhydrophobic insulating corrosion-resistant coating:

[0033] Dissolving alkali lignin in a polar solvent,

[0034] Slowly add the initiator to the obtained alkali lignin solution, heat at 90-180°C under the protection of nitrogen, slowly add long-chain alkane methoxysilane, and obtain a modified alkali lignin solution after the reaction. The modified alkali lignin solution Precipitate and purify, precipitate alkali lignin modified products, dry for later use,

[0035] The modified alkali lignin is added to the hydrophobic resin solution, stirred, and a curing agent is added to obtain the nano lignin fluorine-free super-hydrophobic coating.

[0036] The invention also relates to a lignin / resin superhydrophobic insulating and corrosion-resistant coating prepared by the preparation method.

[0037] The present invention also relates to the application of the lignin / resin superhydrophobic insulating corros...

Embodiment 1

[0042] a. dissolving polysulfone resin in dichloromethane to make a polysulfone resin solution with a mass fraction of 10%;

[0043] b. dissolving alkali lignin in DMF to make a mass fraction of 8% alkali lignin solution, dissolving sodium methylate in ethanol to make a mass fraction of 1% sodium methylate solution, alkali lignin solution and sodium methylate solution The mixture was mixed slowly, heated to 110°C under the protection of nitrogen, and then slowly added dodecyltrimethoxysilane with a mass fraction of 2%, and the reaction was stirred for 4 hours to form a stable modified alkali lignin solution; Precipitate the modified alkali lignin to obtain the modified alkali lignin and dry it for later use;

[0044] c. Dissolve the modified alkali lignin in DMF to make an alkali lignin modified solution with a mass fraction of 20%, mix the polysulfone resin treated in a with it, stir at room temperature for 1 hour, and then add water-based isocyanate, The mass fraction was 5...

Embodiment 2

[0047] a. get the polyurethane resin and dissolve it in thinner water to make a 50% polyurethane resin solution by mass fraction;

[0048] b. dissolving alkali lignin in DMF to make a mass fraction of 10% alkali lignin solution, dissolving sodium methylate in ethanol to make a mass fraction of 2% sodium methylate solution, alkali lignin solution and sodium methylate solution Mix them slowly, heat to 90°C under the protection of nitrogen, then slowly add tetradecyltrimethoxysilane with a mass fraction of 5.5%, and react with stirring for 5 hours to form a stable modified alkali lignin solution; use ethanol to Precipitate the modified alkali lignin to obtain the modified alkali lignin and dry it for later use;

[0049] c. Dissolve the modified alkali lignin in DMF to make an alkali lignin modified solution with a mass fraction of 25%, mix the polyurethane resin treated in a with it, stir at room temperature for 1.5h, and then add water-based isocyanate, The mass fraction was 4%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

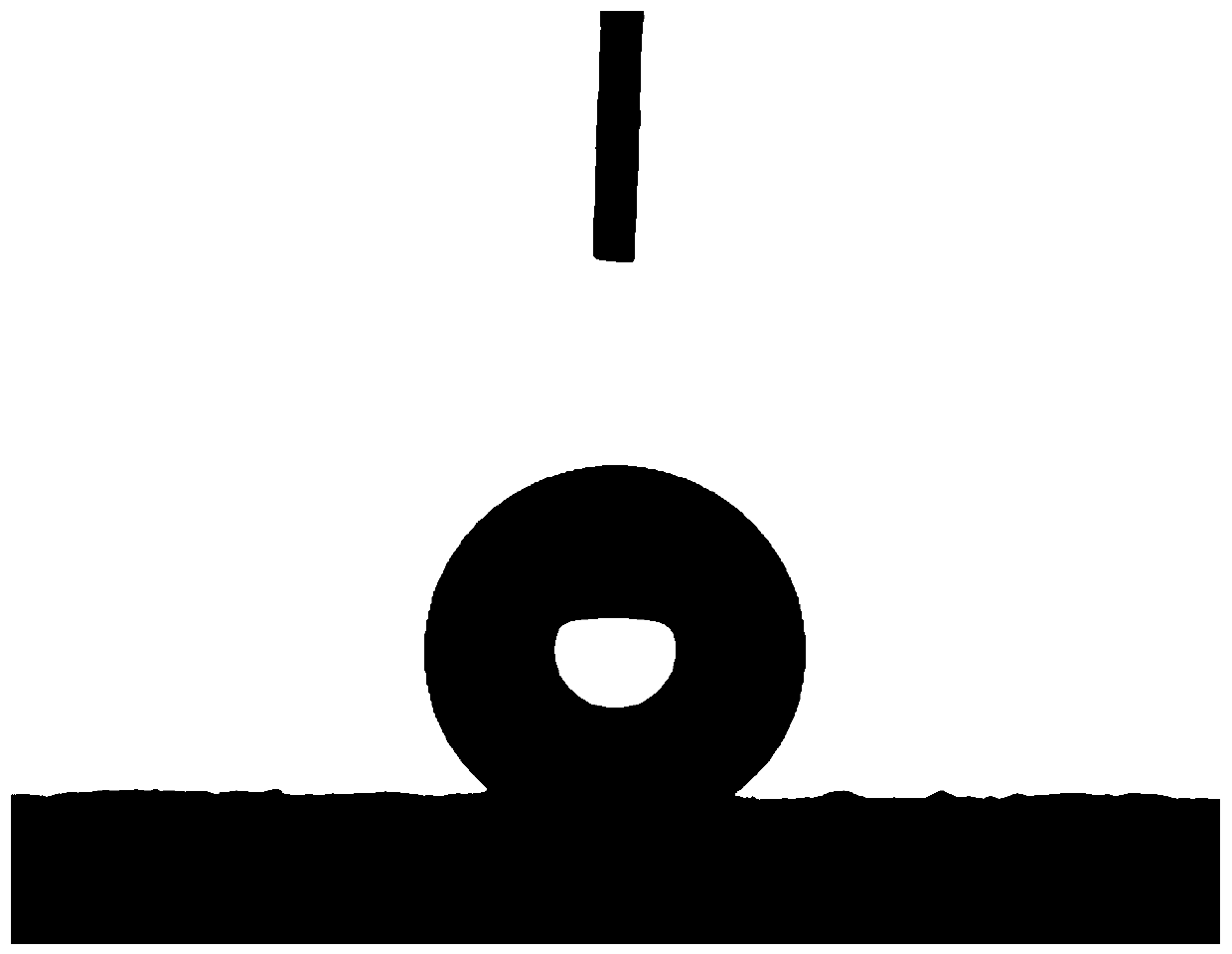

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com