Preparation method of cannabidiol crystals

A technology of cannabidiol and crystals, which is applied in the field of preparation of high-purity cannabidiol crystals, can solve the problems of complex operation, waste of resources, and low extraction rate, and achieve low organic solvent consumption, short production cycle, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

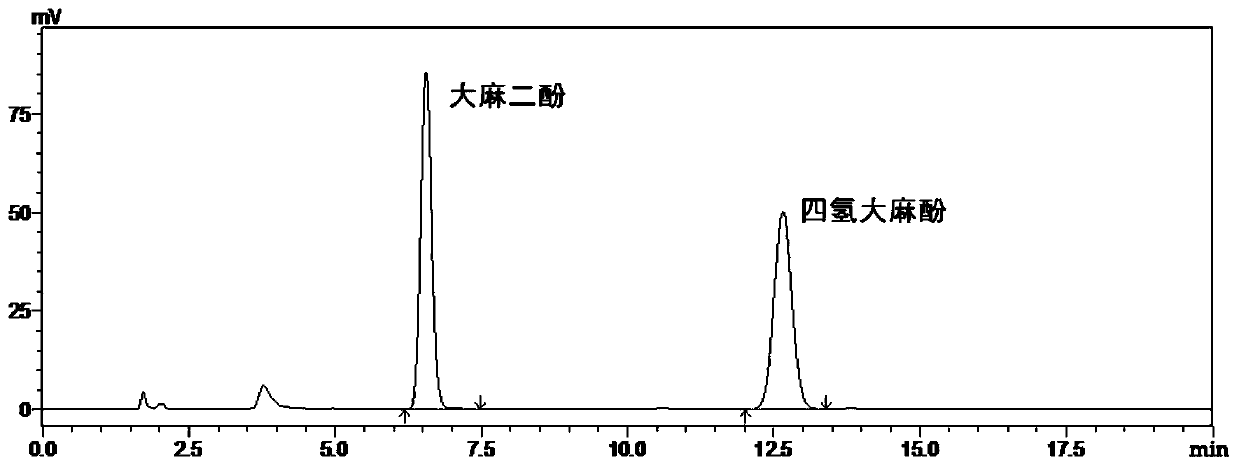

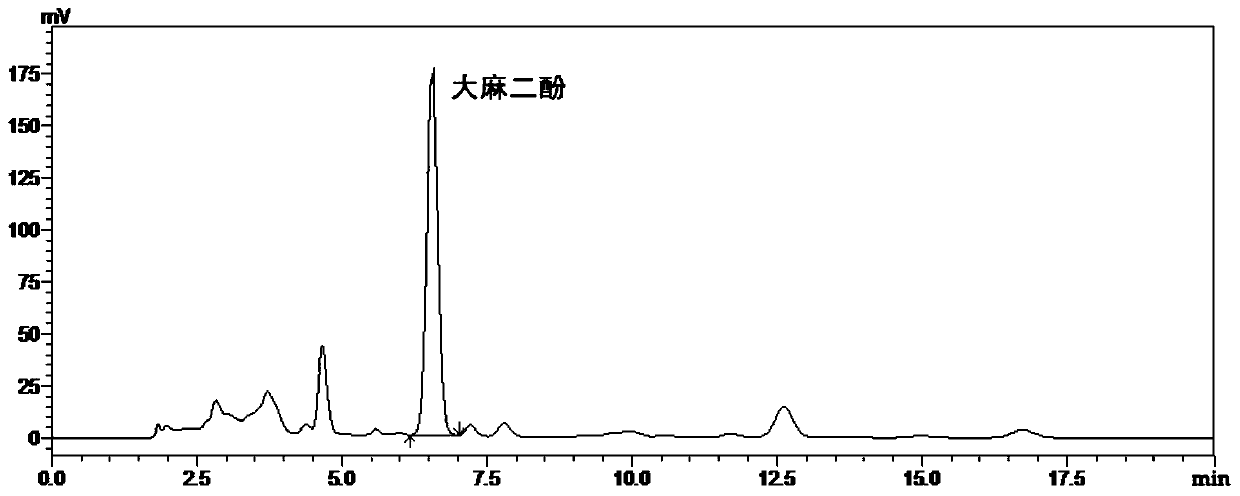

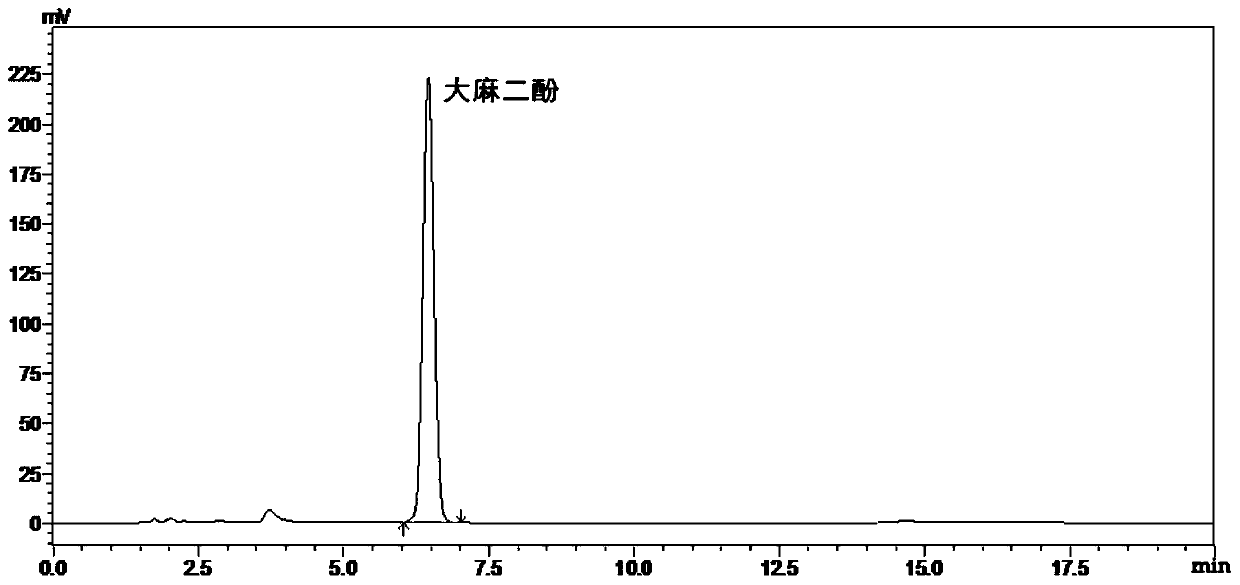

Image

Examples

preparation example Construction

[0029] Specifically, the present invention provides a method for preparing cannabidiol crystals, characterized in that the method comprises the following steps:

[0030] (1) Decarboxylation and extraction are carried out to the floral and leaf powder of industrial hemp to obtain a decarboxylated extract;

[0031] (2) Mixing the decarboxylated extract with the first solvent, standing for precipitation at a temperature lower than 20°C, separating and removing the precipitate, and concentrating the solvent containing cannabidiol to obtain a concentrated extract;

[0032] (3) The concentrated extract is mixed with a second solvent and filtered, and the filtrate is subjected to high-pressure preparative liquid chromatography to collect fractions containing cannabidiol, and then remove the solvent in the fractions to obtain crude cannabidiol;

[0033] (4) The cannabidiol crude product is mixed with a crystallization solvent, and crystallized at a temperature lower than room temperat...

Embodiment 1

[0086] Weigh 10 kg of industrial hemp leaf powder with a particle size of 60 meshes and a CBD content of 0.94%, and decarboxylate it at 100° C. for 2 hours at high temperature.

[0087] Then, under heating to keep the temperature at 60°C, mix the decarboxylated powder and n-hexane at a weight ratio of 1:6, extract for 2 hours under stirring, and recover CBD-containing n-hexane. Repeat the extraction step 2 more times. The recovered n-hexanes were combined, evaporated and concentrated to obtain 690 g of extract extract with a CBD content of 13.4%.

[0088] The extract was mixed with absolute ethanol at a weight ratio of 1:10, and left to settle at 4°C for 4 hours, and then DL-6000B low-speed refrigerated centrifuge was centrifuged at 1000rpm to remove the sediment. Concentrate the absolute ethanol containing CBD to obtain 580 g of treated extract with a CBD content of 15.3%.

[0089] Weigh 200g of the treated extract and mix it with a mixed solvent of petroleum ether and acet...

Embodiment 2

[0093] Weigh 10 kg of industrial hemp leaf powder with a particle size of 60 meshes and a CBD content of 0.94%, and decarboxylate it at 100° C. for 2 hours at high temperature.

[0094] Then, under heating to keep the temperature at 60°C, mix the decarboxylated powder with 95% ethanol at a weight ratio of 1:6, extract for 2 hours under stirring, and recover CBD-containing ethanol. Repeat the extraction step 2 more times. The recovered ethanol was combined, evaporated and concentrated to obtain 1780 g of extract extract with a CBD content of 5.12%.

[0095] The extract was mixed with absolute ethanol at a weight ratio of 1:10, and left to settle at 4°C for 4 hours, and then centrifuged at 1000rpm in a low-speed refrigerated centrifuge to remove the sediment. Concentrate the absolute ethanol containing CBD to obtain 760 g of treated extract with a CBD content of 11.6%.

[0096] Weigh 200g of the treated extract and mix it with a mixed solvent of petroleum ether and acetone (th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com