A composite body pigment and filler with antirust and flame retardant properties and preparation method thereof

A technology of flame retardant properties and composites, applied in the field of composite pigments and fillers and its preparation, can solve problems such as performance needs to be improved, insufficient adhesion, environmental pollution, etc., to enhance market competitiveness and application range, and improve antirust performance , Expand the effect of high value-added applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

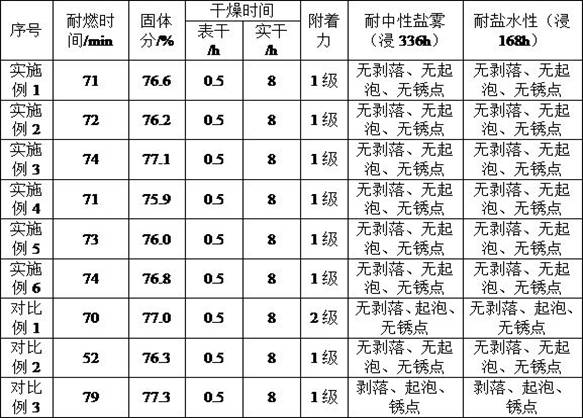

Examples

Embodiment 1

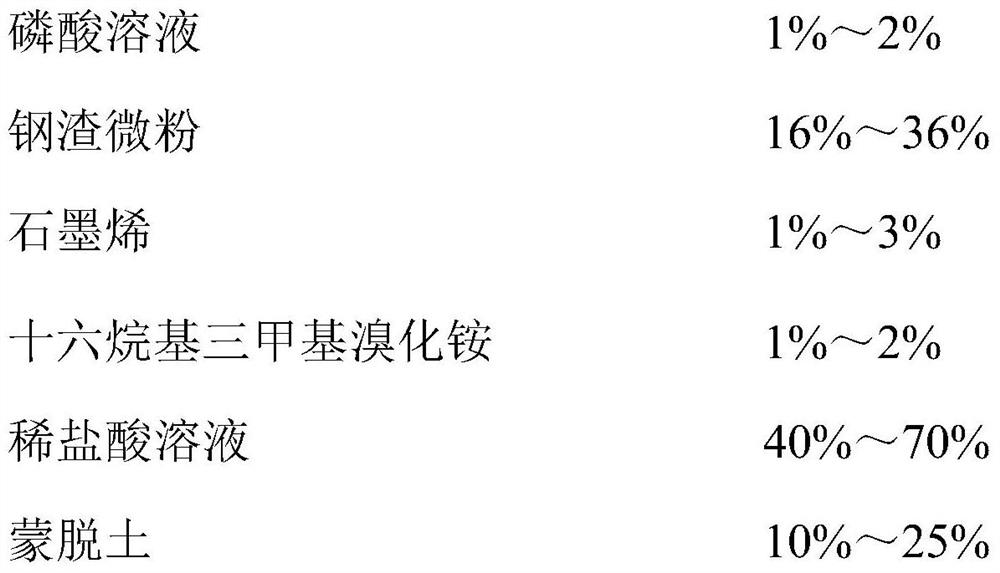

[0032] Taking the preparation of product 100g of the present invention as an example, the used component and its mass ratio are:

[0033] Phosphoric acid solution 1.6%

[0034] Steel slag powder 32%

[0035] Graphene 1%

[0036] Cetyltrimethylammonium bromide 1.4%

[0037] Dilute hydrochloric acid solution 48%

[0038] Montmorillonite 16%

[0039] The mass fraction of the phosphoric acid solution is 86%; the steel slag micropowder is electric furnace drum slag micropowder, and its particle size is 25µm to 45µm; the graphene is analytically pure; the cetyltrimethylammonium bromide is Analytical purity; the mass fraction of the dilute hydrochloric acid solution is 3%; the montmorillonite is calcium-based montmorillonite.

[0040]Firstly, the phosphoric acid solution and the steel slag micropowder were mixed at room temperature with a constant temperature magnetic stirrer, the stirring speed was 800r / min, and the stirring time was 7h to obtain the porous steel slag micropowd...

Embodiment 2

[0045] Taking the preparation of product 100g of the present invention as an example, the used component and its mass ratio are:

[0046] Phosphoric acid solution 1.8%

[0047] Steel slag powder 28%

[0048] Graphene 3%

[0049] Cetyltrimethylammonium bromide 1.2%

[0050] Dilute hydrochloric acid solution 44%

[0051] Montmorillonite 22%

[0052] The mass fraction of the phosphoric acid solution is 82%; the steel slag micropowder is a mixture of hot slag micropowder and converter drum slag micropowder, and its particle size is 25µm to 45µm; the graphene is analytically pure; the hexadecyl Trimethylammonium bromide is of analytical grade; the mass fraction of the dilute hydrochloric acid solution is 6%; the montmorillonite is magnesium-based montmorillonite.

[0053] First, the phosphoric acid solution and the steel slag micropowder were mixed at room temperature with a constant temperature magnetic stirrer, the stirring speed was 950r / min, and the stirring time was 6h to...

Embodiment 3

[0058] Taking the preparation of product 100g of the present invention as an example, the used component and its mass ratio are:

[0059] Phosphoric acid solution 2%

[0060] Steel slag powder 16%

[0061] Graphene 2%

[0062] Cetyltrimethylammonium bromide 2%

[0063] Dilute hydrochloric acid solution 53%

[0064] Montmorillonite 25%

[0065] The mass fraction of the phosphoric acid solution is 80%; the steel slag micro-powder is a mixture of air-quenched slag micro-powder and electric furnace hot-splashing slag micro-powder, and its particle size is 25µm-45µm; the graphene is analytically pure; the hexadecane The base trimethylammonium bromide is of analytical grade; the mass fraction of the dilute hydrochloric acid solution is 5%; the montmorillonite is sodium-calcium montmorillonite.

[0066] Firstly, the phosphoric acid solution and the steel slag micropowder were mixed at room temperature with a constant temperature magnetic stirrer, the stirring speed was 1000r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com