Continuous microwave sintering or melting forming method and device of dielectric material

A technology of microwave sintering and molding method, applied in microwave heating, lighting and heating equipment, electrical components and other directions, can solve the problems of difficult operation and maintenance, high equipment investment and production cost, greenhouse gas emission environment, etc., to reduce production investment and The effect of production operation cost, improving production efficiency and product quality, reducing emissions and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

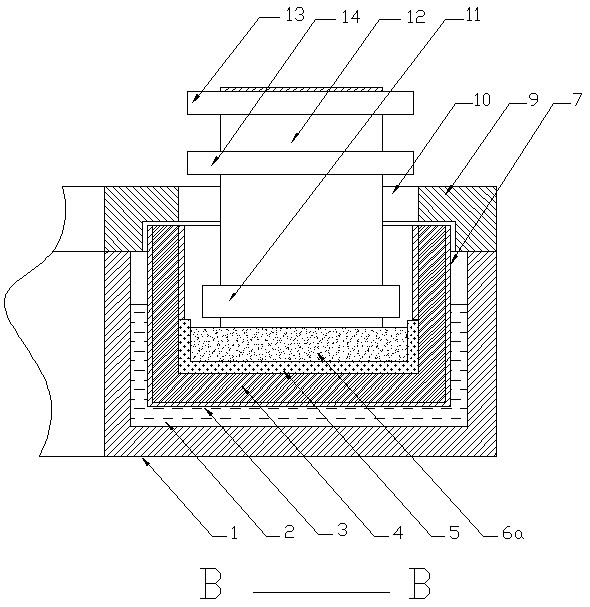

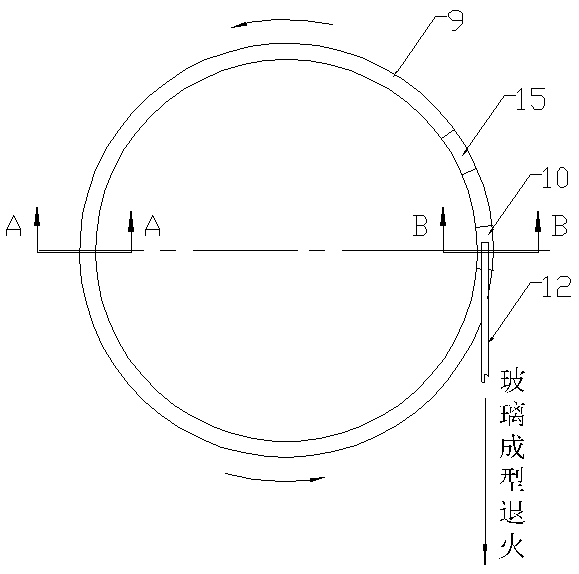

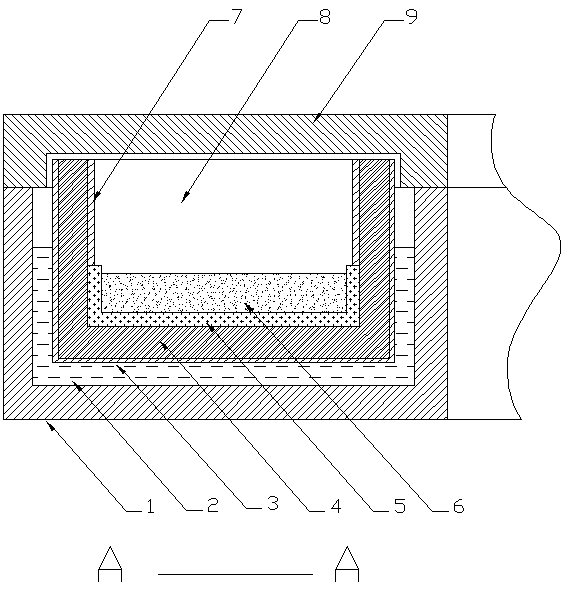

[0019] figure 1 , figure 2 , image 3 Among them, the microwave oven adopts a structure layer of metal shell material layer 3 / insulation material layer 4 / microwave absorbing material layer 5, which is combined to form the furnace bottom structure of the microwave oven; The material inlet 15 on the roof 9 continuously compacts and covers the dielectric raw materials 6 (such as ceramic raw materials, cement raw materials, glass batch materials, etc.) that need to be sintered or melted on the microwave absorbing material layer 5; The microwave source (not shown in the figure) installed on the static and fixed annular furnace roof 9 or the furnace side guides the microwave into the microwave oven cavity 8, and radiates the microwave evenly on the furnace bottom through direct radiation and reflection; normal temperature When the dielectric material 6 that needs to be sintered or melted does not absorb microwaves, the microwaves are transmitted through it and are rapidly absorbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com