Soluble kelp powder containing brown algae oligosaccharide and enzyme method production method of soluble kelp powder

A technology of brown algae oligosaccharide and kelp powder is applied in the directions of food forming, food science, application, etc., can solve the problems of low yield of brown algae oligosaccharide, extensive process, pollute the environment, etc. Yield-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Raw material processing: Weigh fresh kelp (or kelp scraps), soak in clean water for 0.5h, wash away the sediment and mucus, then blanch with hot water at 40-60°C to soften, and then add 3 times the volume Water, beat into kelp slurry with a beater.

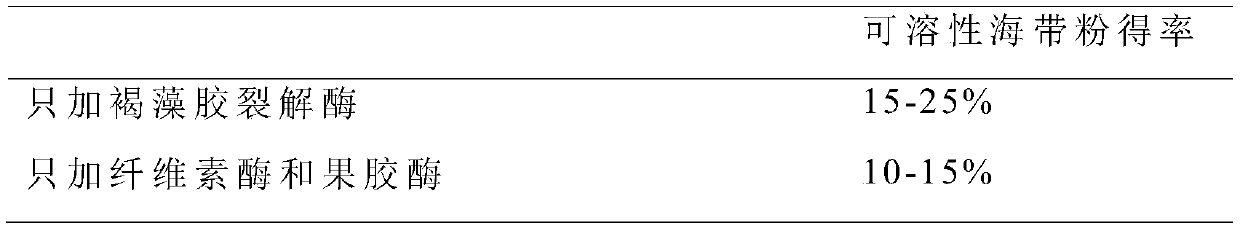

[0029] (2) Enzymolysis: put the kelp pulp described in step (1) into the enzymolysis tank, add alginate lyase with a wet weight of 1‰ of kelp (prepared by the method described in Example 2) and 1% Cellulase, enzymolysis for 2-4 hours to obtain enzymolysis reaction slurry, the reaction temperature is 35-40°C, pH 6.5-7.5, NaCl concentration 300mM. The specific enzyme activity of cellulase is 10,000 U / g, and the specific enzyme activity of alginate lyase is 20,000 U / g.

[0030] (3) Centrifugal filtration: centrifuge (13000g) the enzymolysis reaction slurry described in step (2) with a centrifuge to obtain a supernatant containing fucoidan oligosaccharides and other soluble components, and the residue is used to produce se...

Embodiment 2

[0035] The preparation method of embodiment 2 alginate lyase

[0036] A Screening Method for Vibrio natriegens

[0037] (1) The sea mud was sampled near the kelp breeding factory in Rongcheng City, Shandong Province, and 1g of the sample was taken and dispersed evenly in 50mL of sterile water.

[0038] (2) Inoculate 1 mL of supernatant into 50 mL of screening liquid medium, culture at 28°C and 200 rpm for 2 days, and dilute 10 -6 And spread it on the screening plate medium, culture at 28°C for 2 days, pick single colonies of different shapes and streak the plates several times to obtain pure cultures.

[0039](3) Pick single colonies of different forms, inoculate them in liquid medium, and culture them at 28°C and 200rpm for 2 days, take the supernatant to measure the enzyme activity of the strain, select a strain with higher enzyme activity, and entrust the China Center for Typical Culture Collection to preserve it. The morphological characteristics, physiological and bioch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com