Catalyst and preparation method thereof

A catalyst and auxiliary technology, which is applied in the field of hydrogen peroxide catalyst and its preparation, can solve the problems of poor catalytic reaction selectivity, small specific surface area and pore volume, and high preparation cost, and achieves the improvement of electron density, changes in adsorption characteristics, and weakens interactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

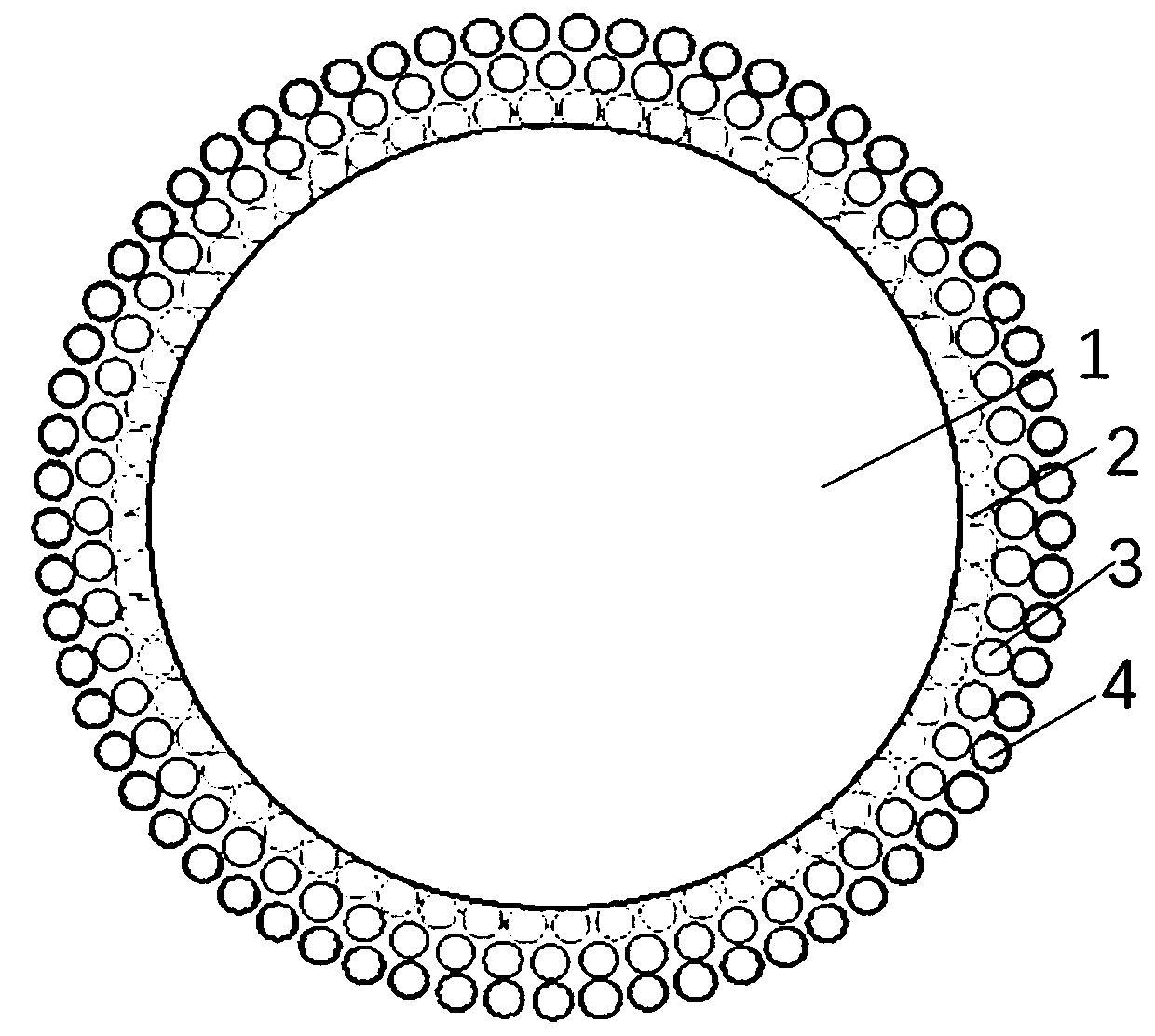

Image

Examples

Embodiment 1

[0092] Dilute 3mL of chloropalladium acid solution with a palladium concentration of 0.01g / mL to 13mL, impregnate 10g of activated alumina in equal volume, dry at 80°C for 2h, and roast at 550°C for 4h to obtain a catalyst with a Pd loading of 0.3% (c-0.3 %Pd).

[0093] The pore structure was tested with a BET analyzer, and the analysis results are shown in Table 1.

[0094] Catalyst dispersion, Pd particle size, hydrogenation efficiency and selectivity are shown in Table 2.

Embodiment 2

[0096] Using 13.3g La(NO 3 ) 3 .6H 2 10g of activated alumina was impregnated with an equal volume of a solution with an O concentration of 10% by weight, dried at 80°C for 2h, and calcined at 550°C for 4h to obtain La 2 o 3 La with a mass fraction of 5% 2 o 3 / Al 2 o 3 ball.

[0097] Dilute 3 mL of chloropalladium acid solution with a palladium concentration of 0.01 g / mL to 13 mL, and impregnate the above La 2 o 3 / Al 2 o 3 Balls were dried at 80°C for 2h and calcined at 550°C for 4h to obtain a catalyst with a Pd loading of 0.3% (c-5%La 2 o 3 -0.3% Pd).

[0098] The pore structure was tested with a BET analyzer, and the analysis results are shown in Table 1.

[0099] Catalyst dispersion, Pd particle size, hydrogenation efficiency and selectivity are shown in Table 2.

Embodiment 3

[0101] Dilute 3 mL of chloropalladium acid solution with a palladium concentration of 0.01 g / mL to 30 mL, add 10 g of functionalized titania-modified alumina support, then add 4 mL of 0.05 g / mL ascorbic acid, and stir the above mixture magnetically at 80 °C 2h, a catalyst with a Pd loading of 0.3% (f-TiO 2 / 0.3% Pd).

[0102] The pore structure was tested with a BET analyzer, and the analysis results are shown in Table 1.

[0103] Catalyst dispersion, Pd particle size, hydrogenation efficiency and selectivity are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com