Preparation method of graphene film

A graphene film, graphene technology, applied in the direction of graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of poor composite quality, mechanical properties of composite films, influence of electrical conductivity, limited contact area, etc., to achieve bonding force Increase, improve mechanical strength and electrical and thermal conductivity, the effect of good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

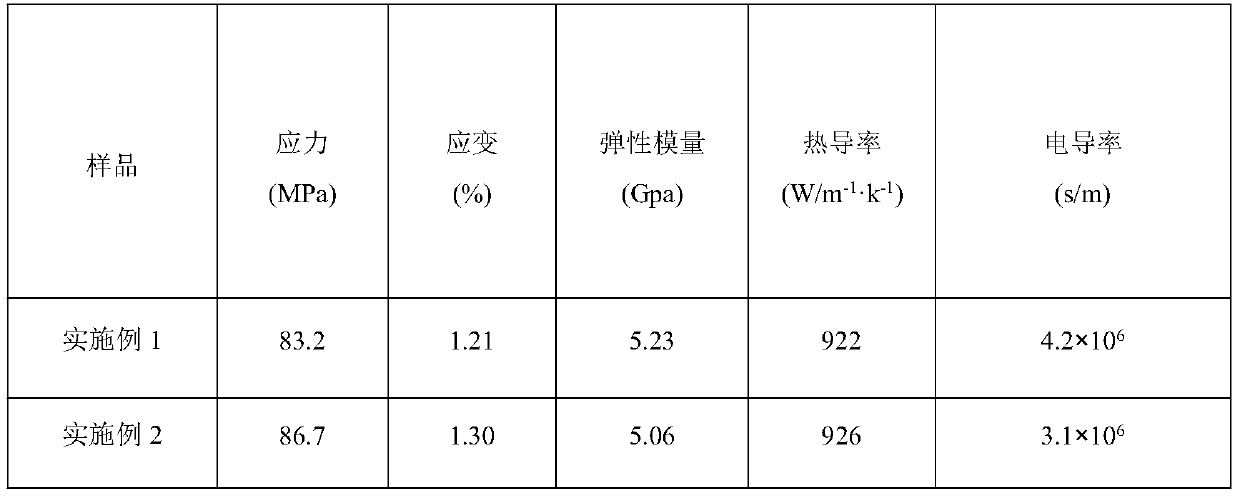

Examples

Embodiment 1

[0015] A kind of preparation method of graphene thin film, it is to carry out according to the following steps:

[0016] (1) Preparation of hydroxylated multi-walled carbon nanotubes: the multi-walled carbon nanotubes were added to the mixed solution of concentrated nitric acid and concentrated sulfuric acid, and the volume ratio of concentrated nitric acid and concentrated sulfuric acid added to the mixed solution was 1:2, 60 Sonicate at ℃ for 6 hours, then add deionized water to wash until pH = 7, add ethylene glycol solution and potassium hydroxide solution dropwise in turn, treat with ultrasonic oscillation for 8 hours, wash and filter with water until pH = 7, and obtain surface hydroxylated multi-walled carbon after drying Nanotube; Wherein, the volume ratio of the quality of multi-walled carbon nanotube, the volume of ethylene glycol solution and potassium hydroxide solution is 1g:45ml:5ml;

[0017] (2) Surface modification of graphene: ultrasonically disperse graphene o...

Embodiment 2

[0021] A kind of preparation method of graphene thin film, it is to carry out according to the following steps:

[0022] (1) Preparation of hydroxylated multi-walled carbon nanotubes: Add multi-walled carbon nanotubes to a mixed solution of concentrated nitric acid and concentrated sulfuric acid, add concentrated nitric acid and concentrated sulfuric acid to the mixed solution at a volume ratio of 1:3, 50°C Ultrasound for 8 hours, then add deionized water to wash to pH = 7, add ethylene glycol solution and potassium hydroxide solution dropwise in turn, ultrasonically oscillate for 5-12 hours, wash and filter to pH = 7, and dry to obtain surface hydroxylated multi-walled Carbon nanotube; Wherein, the volume ratio of the quality of multi-walled carbon nanotube, the volume of ethylene glycol solution and potassium hydroxide solution is 1g:50ml:3ml;

[0023] (2) Surface modification of graphene: ultrasonically disperse graphene oxide in DMF, then add NaOH and succinic acid peroxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com