Treatment method of printing and dyeing wastewater by combined adsorption, flocculation and membrane separation

A technology for printing and dyeing wastewater and a treatment method, which is applied in the field of printing and dyeing wastewater treatment, can solve the problems of easy cracking of ceramic filter membranes, complicated preparation procedures, poor resistance to mechanical damage, etc., and achieves good removal effect, good binding, and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

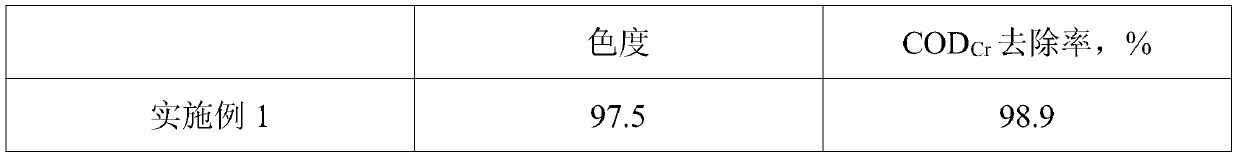

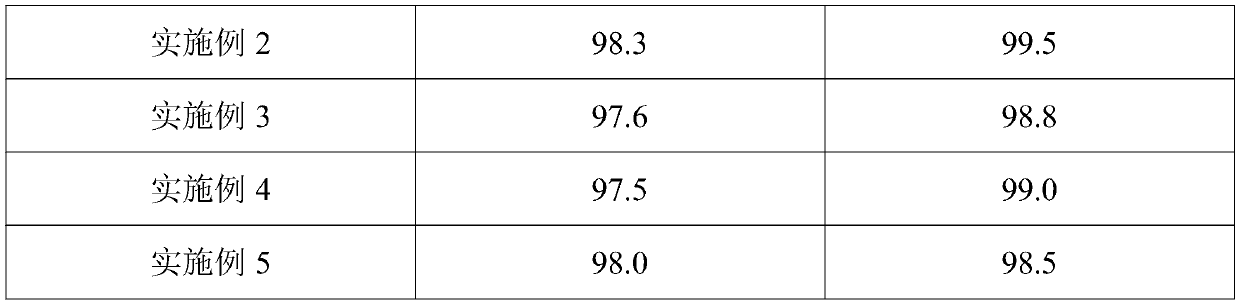

Examples

Embodiment 1

[0030] A method for treating printing and dyeing wastewater combined with adsorption-flocculation-membrane separation, comprising the following steps:

[0031] (1) Add 10g of 3-chloro-2-hydroxypropyltrimethylammonium chloride to deionized water to prepare a modified solution, mix 0.008g of chitosan and deionized water and stir at 50°C until the solid dissolves , prepare the chitosan aqueous solution, and mix it with the modified solution evenly, then add ammonia water to adjust the pH of the solution to 10-12, reflux at 100°C for 3 hours, cool to room temperature after the reaction, filter, and dry the solid , making quaternized chitosan;

[0032] (2) Sodium alginate and deionized water are mixed and stirred at 40° C. until the solid dissolves to obtain a sodium alginate solution with a mass concentration of 3%, which is added to a calcium chloride solution with a mass concentration of 5%. The mass ratio of sodium alginate to calcium chloride is 2:0.3, keep stirring and react...

Embodiment 2

[0038] A method for treating printing and dyeing wastewater combined with adsorption-flocculation-membrane separation, comprising the following steps:

[0039] (1) Add 10g of 3-chloro-2-hydroxypropyltrimethylammonium chloride to deionized water to prepare a modified solution, mix 0.015g of chitosan and deionized water and stir at 50°C until the solid dissolves , prepare the chitosan aqueous solution, and mix it with the modified solution evenly, add ammonia water to adjust the pH of the solution to 10-12, reflux at 150°C for 3 hours, cool to room temperature after the reaction, filter, and dry the solid , making quaternized chitosan;

[0040] (2) Sodium alginate and deionized water are mixed and stirred at 40° C. until the solid dissolves to obtain a sodium alginate solution with a mass concentration of 3%, which is added to a calcium chloride solution with a mass concentration of 5%. The mass ratio of sodium alginate to calcium chloride is 2:0.6, keep stirring and reacting a...

Embodiment 3

[0046] A method for treating printing and dyeing wastewater combined with adsorption-flocculation-membrane separation, comprising the following steps:

[0047] (1) Add 10g of 3-chloro-2-hydroxypropyltrimethylammonium chloride to deionized water to prepare a modified solution, mix 0.01g of chitosan and deionized water and stir at 50°C until the solid dissolves , prepare the chitosan aqueous solution, and mix it with the modified solution evenly, then add ammonia water to adjust the pH of the solution to 10-12, reflux at 110°C for 3 hours, cool to room temperature after the reaction, filter, and dry the solid , making quaternized chitosan;

[0048] (2) Sodium alginate and deionized water are mixed and stirred at 40° C. until the solid dissolves to obtain a sodium alginate solution with a mass concentration of 3%, which is added to a calcium chloride solution with a mass concentration of 5%. The mass ratio of sodium alginate to calcium chloride is 2:0.4, keep stirring and reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com