Self-lubricating composite coating with resistance to marine corrosion and wear and production technology of self-lubricating composite coating with resistance to marine corrosion and wear

A composite coating and preparation technology, which is applied in coatings, anti-corrosion coatings, polyamide coatings, etc., can solve problems such as corrosion and wear of transmission parts, and achieve the effects of small size restrictions, excellent mechanical properties, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this example, 304 stainless steel is used as the alloy substrate, coated with a marine corrosion-resistant, wear-resistant self-lubricating composite coating, and the preparation process is as follows:

[0034] (1) According to the proportion, solid epoxy resin (E20) 12%, epoxy modified silicone resin (SH-023-7) 18%, polyamide resin (650) 6%, wetting and dispersing agent (SOLSPERSE32500) 4% (mass fraction) Configure organic film-forming substances, stir and disperse at a speed of 800r / min for 10 minutes until uniform and transparent (the total mass fraction of organic film-forming substances accounts for 40%);

[0035] (2) 15% of graphite powder, 22% of silicon carbide powder, and 23% of polytetrafluoroethylene micropowder are added to the mixed resin successively. Stir and disperse for 15 minutes at a speed of 1 / min, and mix evenly to form a mixture;

[0036] (3) Add grinding zirconium beads accounting for 80% of the total mass of the mixture, and grind and dispers...

Embodiment 2

[0041] The difference from Example 1 is that the composite coating formula is changed to:

[0042] In terms of mass percentage, solid epoxy resin (E20) 19%, epoxy modified silicone resin (SH-023-7) 24%, polyamide resin (650) 11%, wetting and dispersing agent (SOLSPERSE32500) 6% , graphite powder 10%, silicon carbide powder 16%, polytetrafluoroethylene powder 14%; among them, the mass fraction of organic film-forming substances accounts for 60% in total;

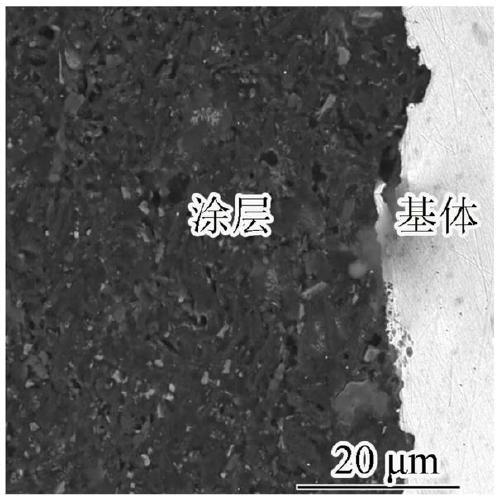

[0043] The thickness of the coating in this embodiment is about 200 μm, and the prepared composite coating has a compact structure, and the cross-sectional appearance is similar to figure 1 Similarly, it is well bonded to the alloy interface, and there is no obvious large hole defect in the coating, no cracks, etc.

Embodiment 3

[0045] The difference from Example 1 is that the composite coating formula is changed to:

[0046] In terms of mass percentage, solid epoxy resin (E20) 15%, epoxy modified silicone resin (SH-023-7) 20%, polyamide resin (650) 8%, wetting and dispersing agent (SOLSPERSE32500) 5% , graphite powder 15%, silicon carbide powder 24%, polytetrafluoroethylene powder 13%; among them, the mass fraction of organic film-forming substances accounts for 48% in total.

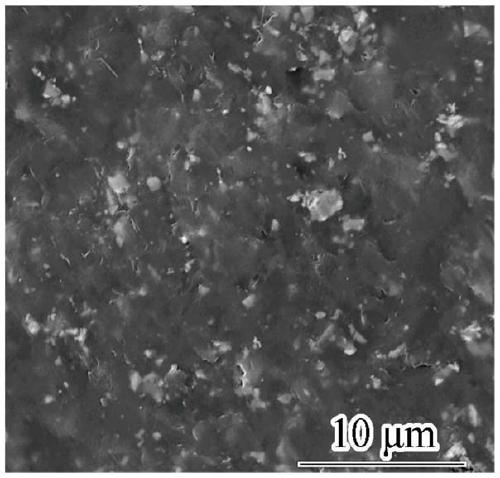

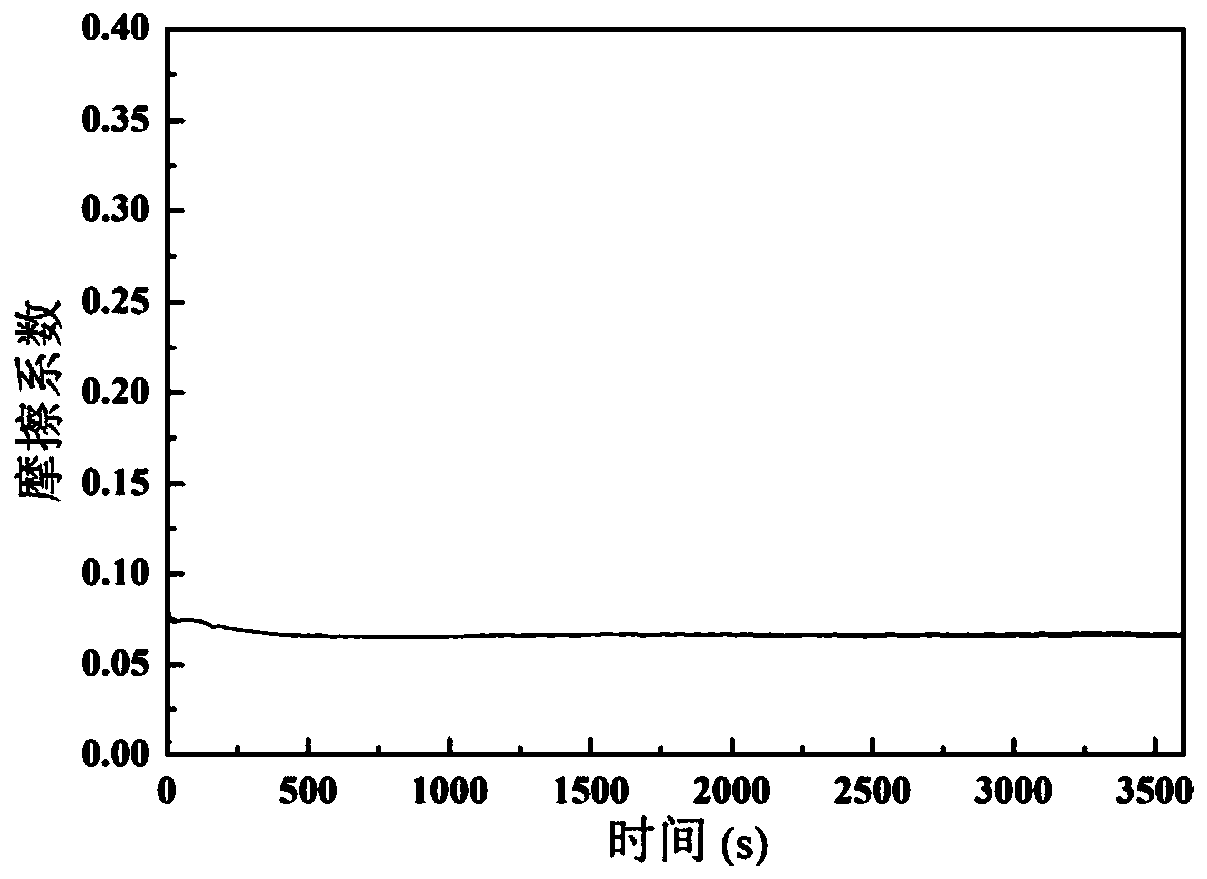

[0047] Coating alloy base material is Q235 steel, such as figure 2 As shown, the thickness of the coating in this example is about 200 μm, and the prepared composite coating has a compact surface appearance, no micron-level and above-sized defects, and the filler is dispersed and evenly distributed in the organic film-forming material, and is combined with the organic film-forming material. The material interface is well bonded. The interface bonding force between the coating and the alloy substrate was tested by pulling me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com