Novel corrosion-resistant nickel-based alloy and production process thereof

A technology of nickel-based alloy and production process, which is applied in the field of new corrosion-resistant nickel-based alloy and its production process, can solve the problems of increased corrosion of heat exchangers, poor corrosion resistance of carbon steel, and easy corrosion, etc. The phase is uniform, the quality of the finished alloy is stable, and the effect of uniformity is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

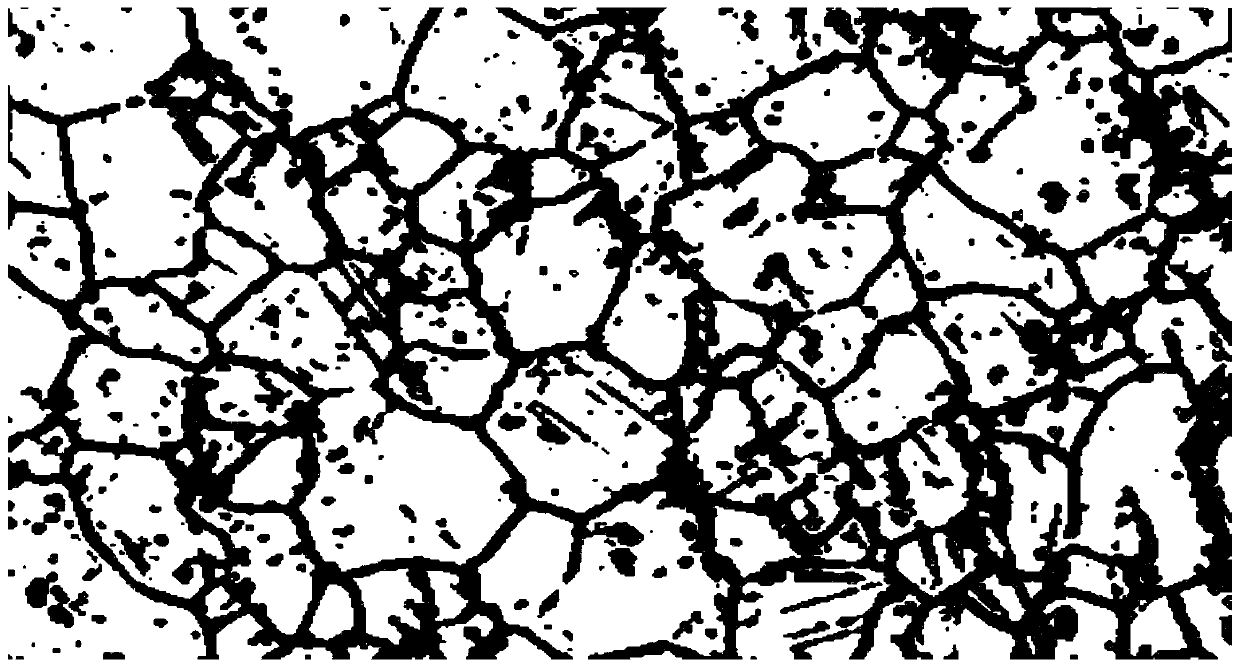

Image

Examples

Embodiment 1

[0051] A new type of corrosion-resistant nickel-based alloy:

[0052] A new type of corrosion-resistant nickel-based alloy, the composition weight percent of which is: Cu: 31.5%, Al: 2.67%, Fe: 1.36%, Cr: 1.23%, Mn: 0.86%, Ti: 0.53%, Nb: 0.34%, Ta: 0.29%, Si: 0.31%, C: 0.046%, S: 0.002%, the balance is Ni;

[0053] The production process of novel corrosion-resistant nickel-based alloy comprises the following steps:

[0054] S10, select raw materials, the weight percent of raw materials is composed of: 31.5% pure copper, 2.67% electrolytic aluminum, 1.36% iron powder, 1.23% pure chromium, 0.86% electrolytic manganese, 0.53% pure titanium, 0.34% niobium, 0.29% tantalum, 0.31% pure silicon, 0.046% carbon powder, 0.002% sulfur, and the rest electrolytic nickel; put the raw materials into a vacuum intermediate frequency melting furnace for melting;

[0055] S20, raising the temperature in the vacuum melting furnace to 1580° C., and then keeping the temperature in the vacuum melti...

Embodiment 2

[0067] A novel corrosion-resistant nickel-based alloy and its production process:

[0068] A new type of corrosion-resistant nickel-based alloy, its composition weight percentage is: Cu: 29.5%, Al: 3.15%, Fe: 1.83%, Cr: 1.48%, Mn: 1.13%, Ti: 0.82%, Nb: 0.61%, Ta: 0.57%, Si: 0.44%, C: 0.085%, S: 0.005%, and the balance is Ni.

[0069] The production process of novel corrosion-resistant nickel-based alloy comprises the following steps:

[0070] S10, select raw materials, the weight percentage of raw materials is composed of: 29.5% pure copper, 3.15% electrolytic aluminum, 1.83% iron powder, 1.48% pure chromium, 1.13% electrolytic manganese, 0.82% pure titanium, 0.61% niobium, 0.57% tantalum, 0.44% pure silicon, 0.085% carbon powder, 0.005% sulfur, and the rest electrolytic nickel; put the raw materials into a vacuum intermediate frequency melting furnace for melting;

[0071] S20, raising the temperature in the vacuum melting furnace to 1630°C, and then keeping the temperature...

Embodiment 3

[0083] A new type of corrosion-resistant nickel-based alloy:

[0084] A new type of corrosion-resistant nickel-based alloy, the weight percentage of which is: Cu: 30.5%, Al: 3.27%, Fe: 1.64%, Cr: 1.37%, Mn: 0.93%, Ti: 0.69%, Nb: 0.51%, Ta: 0.46%, Si: 0.38%, C: 0.068%, S: 0.0035%, and the balance is Ni.

[0085] The production process of novel corrosion-resistant nickel-based alloy comprises the following steps:

[0086] S10, select raw materials, the weight percent of raw materials is composed of: 30.5% pure copper, 3.27% electrolytic aluminum, 1.64% iron powder, 1.37% pure chromium, 0.93% electrolytic manganese, 0.69% pure titanium, 0.51% niobium, 0.46% tantalum, 0.38% pure silicon, 0.068% carbon powder, 0.0035% sulfur, and the rest electrolytic nickel; put the raw materials into a vacuum intermediate frequency melting furnace for melting;

[0087] S20, raising the temperature in the vacuum melting furnace to 1600°C, and then keeping the temperature in the vacuum melting fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com