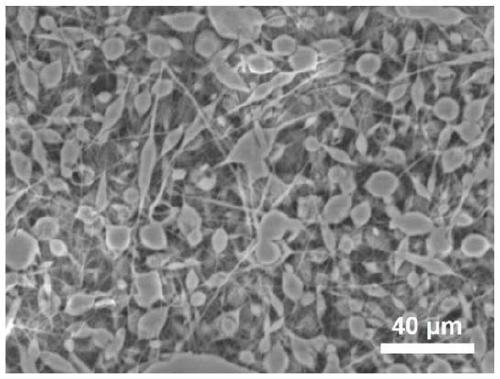

Core-shell self-repairing fiber bead type electrospinning material based on pH response and synthesis method and application thereof

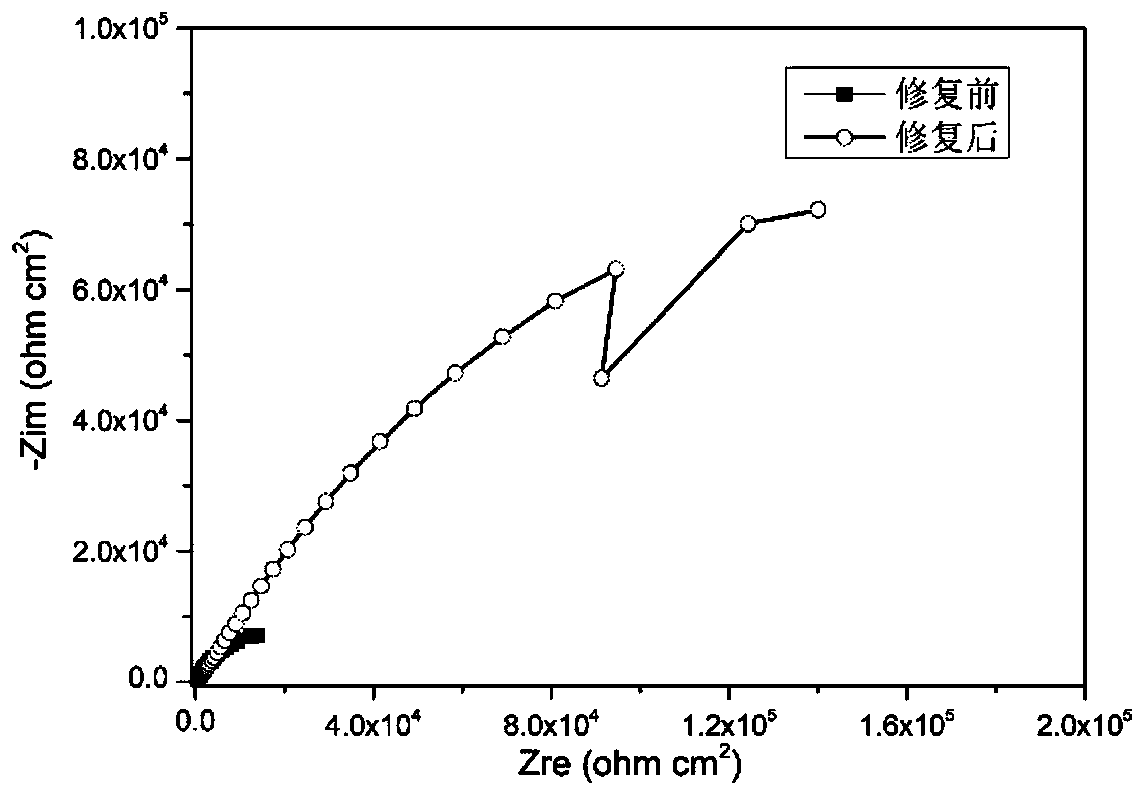

A technology of electrospinning and synthesis method, applied in the field of polymer chemistry, can solve problems such as low repair efficiency and low drug loading, and achieve the effects of increasing drug loading, improving corrosion resistance, and extending transmission paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention is a method for synthesizing a core-shell self-repairing fiber beaded electrospinning material based on a pH response. The specific implementation steps are as follows:

[0048]1) Synthesis of A-component shell solution: polymer shell material, shell material template agent, shell material solvent, crosslinking agent, catalyst according to the mass ratio of 1:0.1-2:5-30:0.2-5:0.075-1 Proportionally weighed, the order of drug addition is:

[0049] 1.1) The polymer shell material and the shell material solvent are mixed first, and stirred at a speed of 600-3000rmp for 4-48 hours in the temperature range of 40-90°C;

[0050] 1.2) Then add the shell material template agent, stir at a speed of 600-3000rmp for 1-4 hours in the temperature range of 50-90°C, and add the crosslinking agent and catalyst respectively;

[0051] 1.3) Finally, in the reflux device, within the temperature range of 40-120°C, stir at a speed of 600-3000rmp for 1-4 hours;

[0052]...

Embodiment 1

[0068] A kind of core-shell self-repairing fiber beaded electrospinning material based on pH response of the present invention, the specific steps of its synthesis method are as follows:

[0069] (1) Synthesis of shell solution of component A: 1 g of polyethylene terephthalate polymer shell material, 1 g of chitin, 0.5 g of pyrrolidine, 5 g of acetone, 20 g of tetrahydrofuran, 1 g of dicumyl peroxide, and dilaurel Weighing of 0.15 g of dibutyltin acid. The order of adding the medicines is that 1g of polyethylene terephthalate polymer shell material, 1g of chitin, 5g of acetone, and 20g of tetrahydrofuran are mixed first, and stirred at a speed of 1000rmp for 6 hours at a temperature range of 45°C. Thereafter, 0.5 g of pyrrolidine was added, and the mixture was stirred at 2000 rpm for 1 hour at a temperature range of 70°C. Add 1 g of dicumyl peroxide and 0.15 g of dibutyltin dilaurate respectively, and stir for 4 hours at a speed of 1000 rpm in a reflux device at a temperature...

Embodiment 2

[0074] A kind of core-shell self-repairing fiber beaded electrospinning material based on pH response of the present invention, the specific steps of its synthesis method are as follows:

[0075] (1) Synthesis of A component shell solution: 0.5g of polyvinylidene fluoride, 1.5g of methyl cellulose, 0.5g of polyvinyl acetate, Al 2 o 3 1g, ZrO 2 1g, 10g of N,N dimethylformamide, 10g of methanol, 4g of dicumyl hydroperoxide, and 0.6g of bismuth isooctanoate were weighed. The order of adding drugs is to mix 0.5g of polyvinylidene fluoride, 1.5g of methyl cellulose, 0.5g of polyvinyl acetate, 10g of N,N dimethylformamide, and 10g of methanol. Stir at 2500rmp for 48 hours. Add Al later 2 o 3 1g, ZrO 2 1 g, stirred at 2000 rpm for 4 hours at a temperature range of 80°C. Add 4 g of dicumyl hydroperoxide and 0.6 g of bismuth isooctanoate respectively, and stir at a speed of 2000 rpm for 2 hours in a reflux device at a temperature range of 100° C.

[0076] (2) Preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com